A Design Method of Panel Design for Combined Building Formwork System

A technology of building formwork and design method, which is applied in the on-site preparation of building components, construction, building construction, etc., can solve the problem of not being able to determine the clear location, type, quantity and reliable connection method of non-standard building formwork, standardization of building formwork , Systematization and industrialization are out of the question, environmental protection and construction cost reduction and ergonomics impact, etc., to reduce the difficulty of construction, improve convenience and reliability, and reduce construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0175] In this example, a plate structural element connected to a beam structural element and a column structural element is taken as an example for illustration.

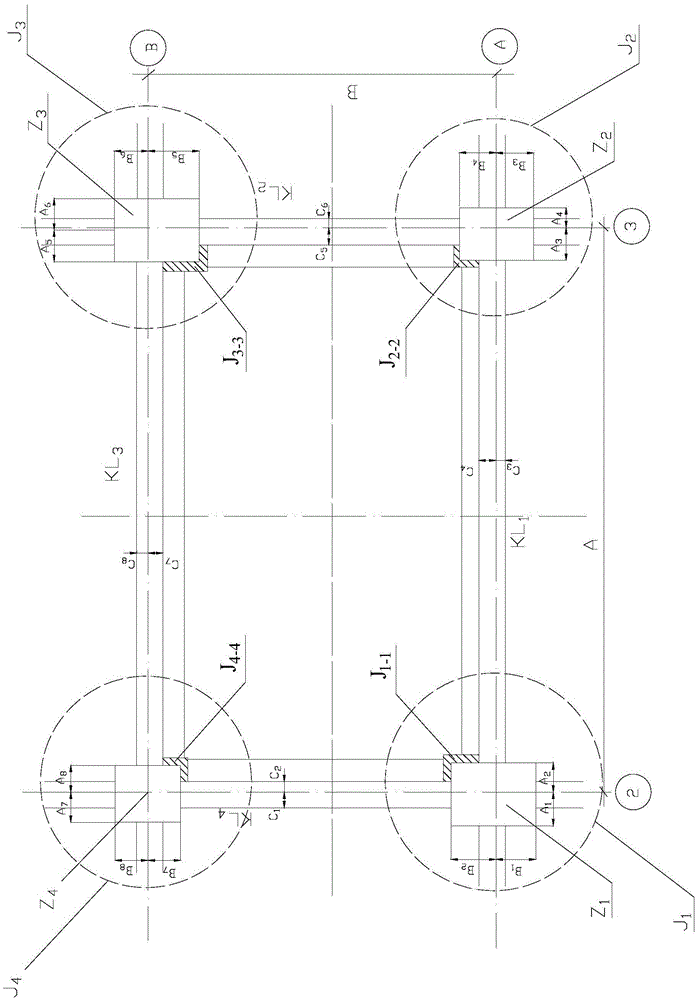

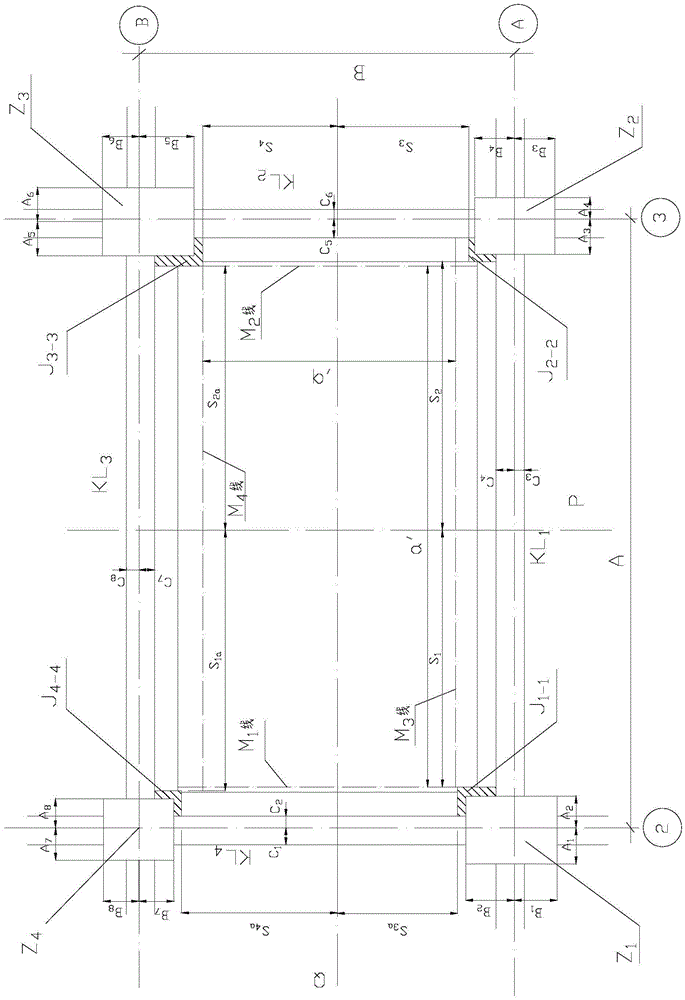

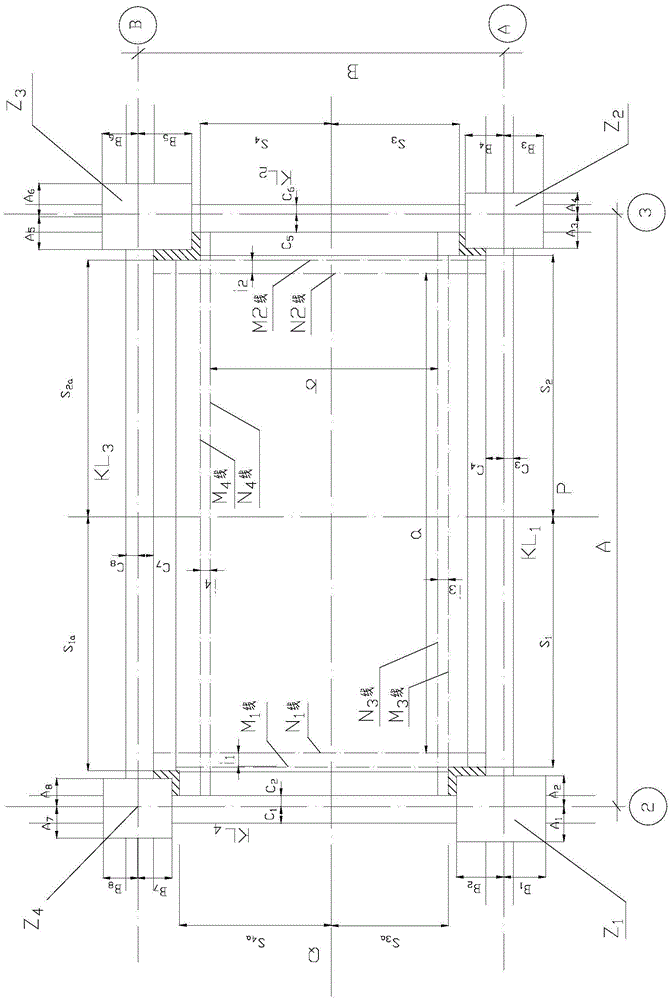

[0176] Such as Figures 1 to 15 , Figures 34 to 38 As shown, the panel design method of the combined building formwork system of the present invention is to divide the construction area of the building formwork to the panel structure unit, and then carry out the panel design according to the divided construction area; wherein, the panel structure unit is constructed The construction area division of formwork refers to:

[0177] Firstly, the construction area of the plate structure unit is divided into standard construction area, non-standard construction area, fixed construction zone, non-standard joint and non-standard joint plate;

[0178] Then, determine the positions and specifications of fixed construction belts, non-standard joints, non-standard gusset plates, standard construction areas and non-standa...

Embodiment 2

[0374] Such as Figure 28 As shown, the plate structure unit in this embodiment is connected with the beam structure unit, and there are no column structure units at the four corners of the plate structure unit. In this embodiment, the design method of the building formwork matching plate for the slab structure unit with beams and no columns is the same as the design method of the building formwork matching plate for the slab structure unit in the first embodiment. When calculating the plane size of each component, the following input condition parameters are specified. Just set:

[0375] A 1 =A 7 =C 1 , A 2 =A 8 =C 2 , A 3 =A 5 =C 5 , A 4 =A 6 =C 6 ;

[0376] B 1 =B 3 =C 3 , B 2 =B 4 =C 4 , B 5 =B 7 =C 7 , B 6 =B 8 =C 8 .

[0377] In this embodiment, there is no need to design building templates for the column structure unit.

Embodiment 3

[0379] Such as Figure 29 As shown, the plate structure unit in this embodiment is connected to the column structure unit, and there are no beam structure units on the four sides of the plate structure unit. In this embodiment, the design method of the building formwork matching plate for the plate structure unit without beams and columns is the same as the design method of the building formwork matching plate for the plate structure unit in Embodiment 1. When calculating the plane size of each component, the following input condition parameters are specially carried out. Just set:

[0380] C 1 =C 2 =C 3 =C 4 =C 5 =C6 =C 7 =C 8 =0.

[0381] At the same time, it is enough to change the building formwork model of the fixed construction belt from the inner corner formwork to the plane formwork. In this embodiment, there is no need to carry out the design of the building formwork matching plate for the beam structure unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com