Tower type oil sucking machine

A tower pumping unit and sucker rod technology, which is applied in the production of fluids, wellbore/well components, earth-moving drilling, etc., can solve the problem of high power consumption, low operating efficiency of beam pumping units, and reliable transmission chain. The performance and service life restrict the development of beamless pumping units, so as to improve the service life and avoid impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

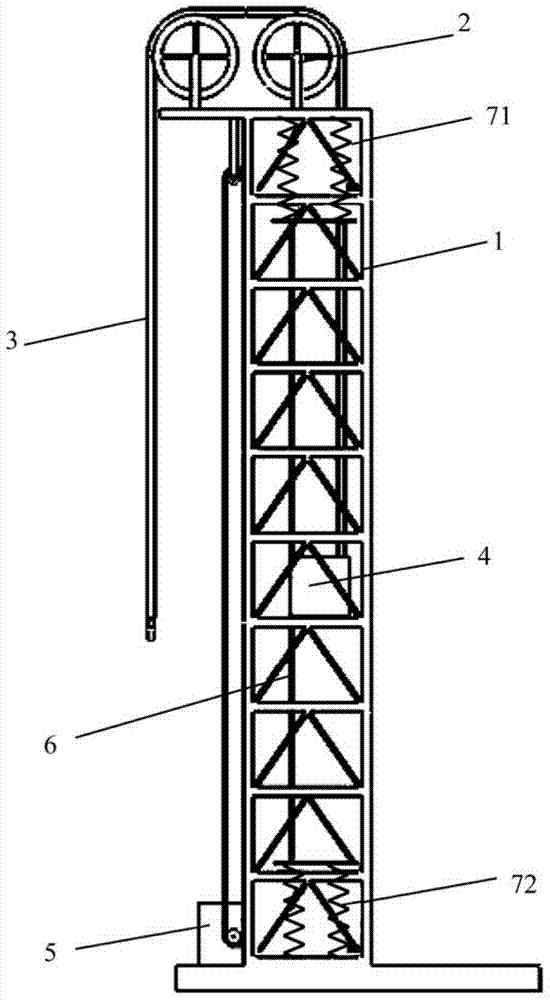

[0020] Such as figure 1 As shown, the motor 5 is fixedly arranged on the frame 1, and the motor 5 drives the fixed pulley 2 to rotate, and drives the counterweight 4 and the sucker rod to move up and down in opposite directions.

Embodiment 2

[0022] Such as figure 2 As shown, the tower pumping unit also includes a chain 6, which is connected end to end to form a closed loop, and the counterweight 4 is fixedly connected to the chain 6; the motor 5 is fixedly arranged on the frame 1, and the motor 5 drives The chain 6 drives the counterweight 4 and the sucker rod to move up and down in opposite directions. That is, the chain 6 driven by the motor 5, the two ends of the chain 6 are connected end to end to form a closed ring, and the counterweight 4 is fixedly connected to the chain 6. It can be understood that the counterweight 4 is connected between the above-mentioned connecting chain 3 and the chain 6. Driven to move up and down.

[0023] Optionally, the tower pumping unit also has a chain positioning device, which is used to position the chain and limit the moving path of the chain. Optionally, there are at least two chain positioning devices: a first chain positioning device and a second chain positioning devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com