Rectangular pipe jacking large-angle obliquely crossing in-tunnel construction method

A technology of rectangular pipe jacking and construction method, which is applied in the direction of earthwork drilling, mining equipment, tunnels, etc., and can solve the problems that the receiving shaft and the pipe jacking axis are not perpendicular to the receiving shaft size, and the receiving shaft cannot be set up.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

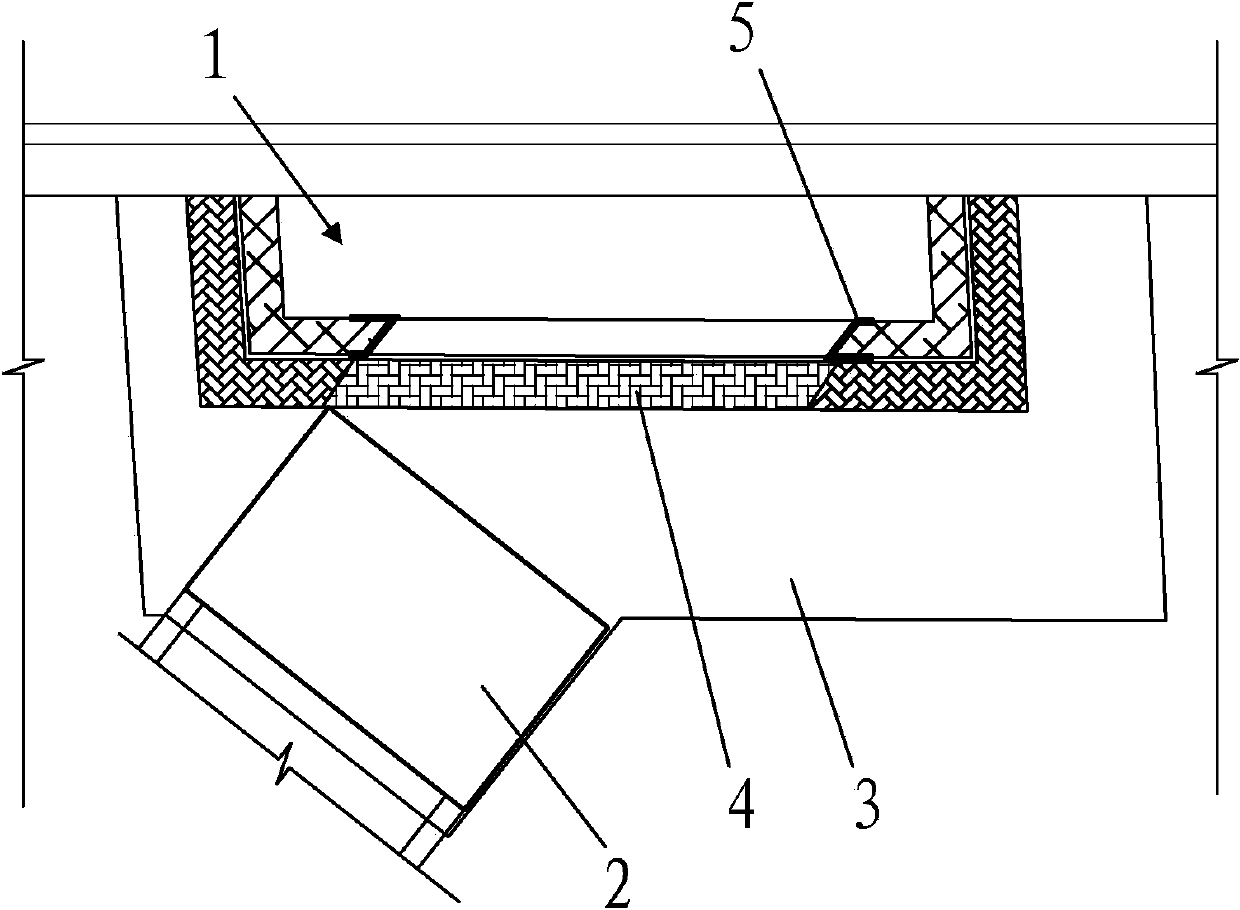

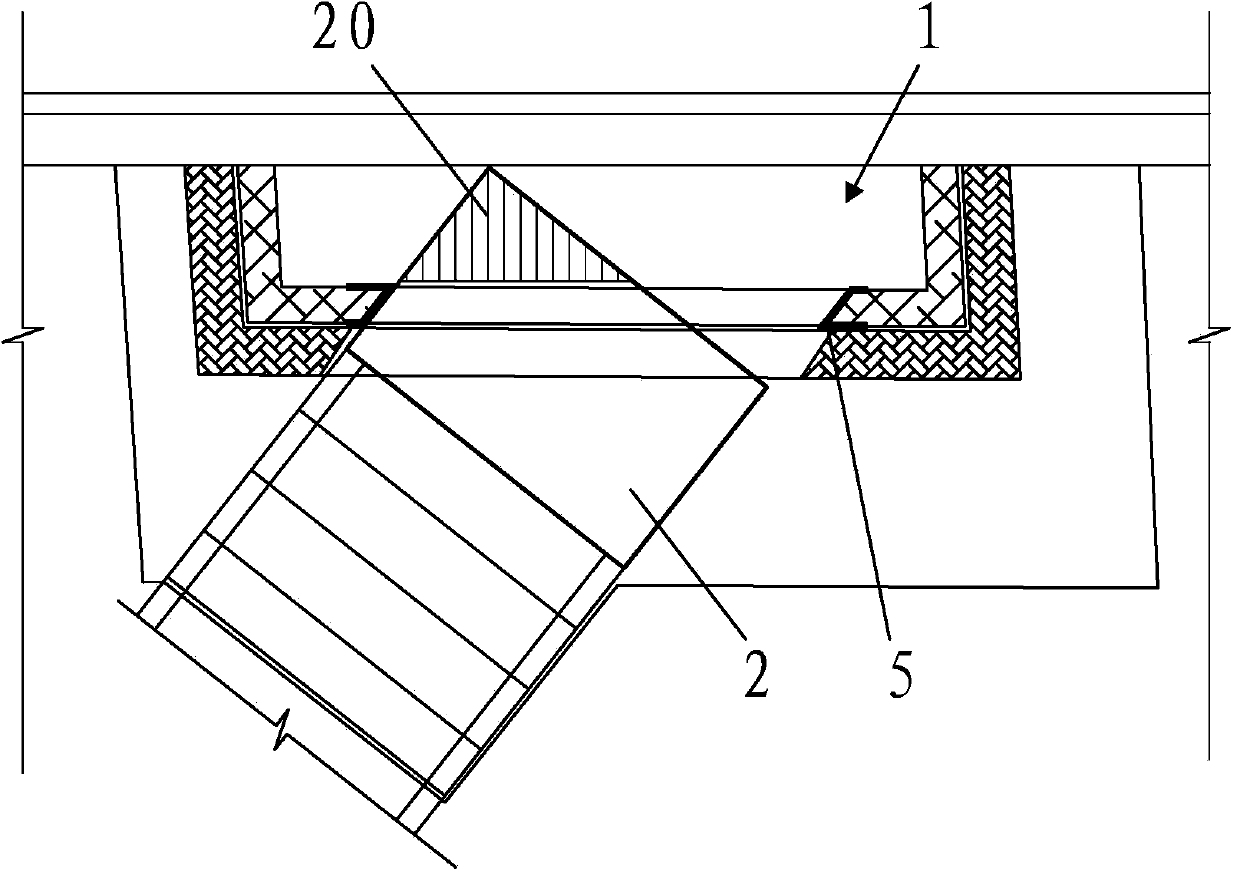

[0023] In order to facilitate the understanding of the structure of the present invention, the following description is given in conjunction with the drawings and embodiments.

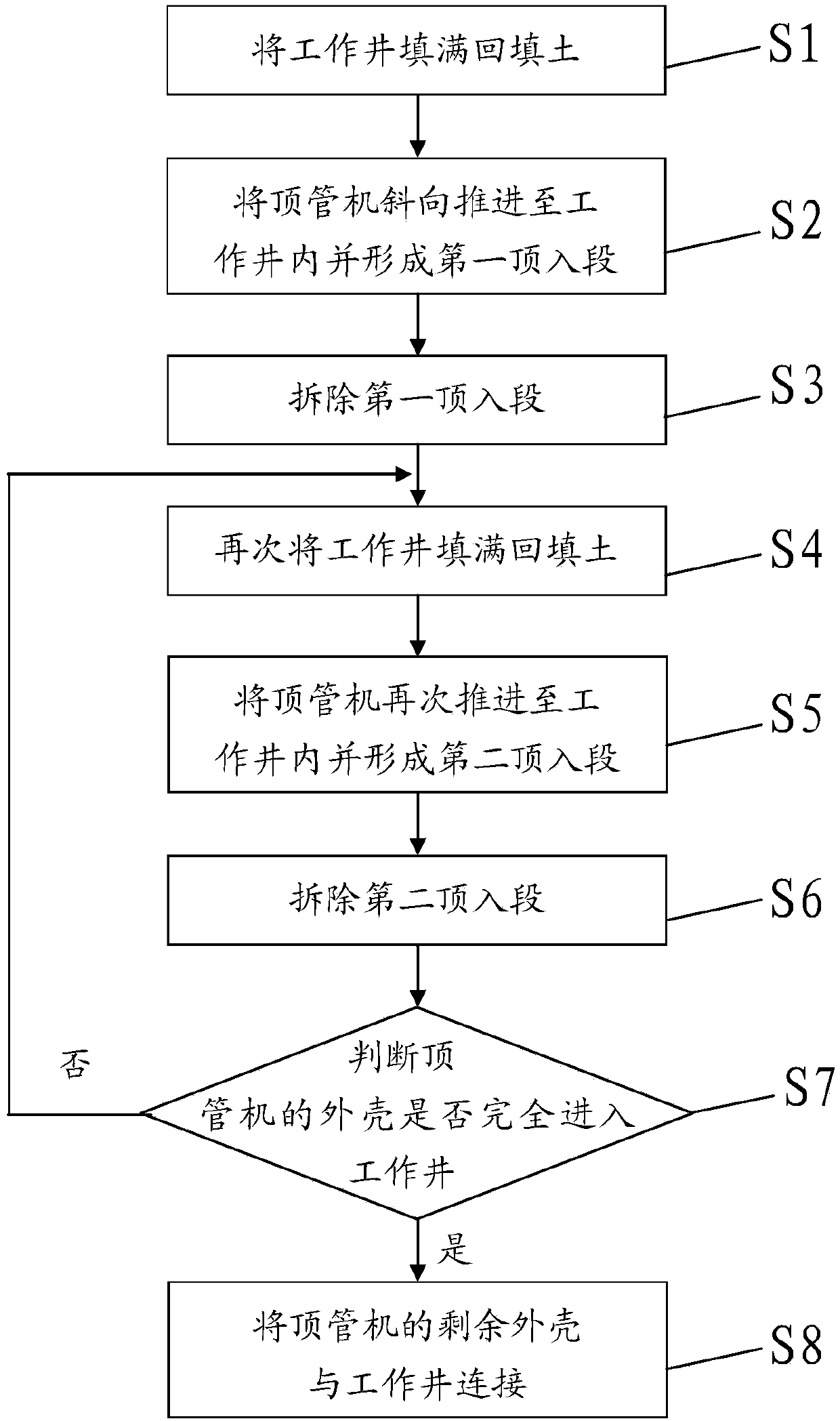

[0024] Reference figure 1 , Is a schematic diagram of the process flow diagram of the large-angle oblique cross-entry construction method of the rectangular jacking pipe of the present invention, such as figure 1 As shown, the present invention provides a large-angle oblique crossing construction method for a rectangular jacking pipe, which combines Figure 2 to Figure 4 , Including the following steps in sequence:

[0025] Step S1, drive the pipe jacking machine 2 diagonally to the front of the working well 1, and fill the working well 1 with backfill;

[0026] Step S2, push the pipe jacking machine 2 obliquely into the working well for the first time to form the first jacking section 20;

[0027] Step S3, excavate the backfill in the working well 1, dismantle the equipment in the first jacking section 20 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com