Brake shoe assembly

A technology of brake shoes and components, which is applied in the direction of brake parts, etc., can solve the problems of increasing the workload of friction plate replacement and reducing the braking capacity of brake shoes, so as to achieve the effect of reducing work intensity and improving braking capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

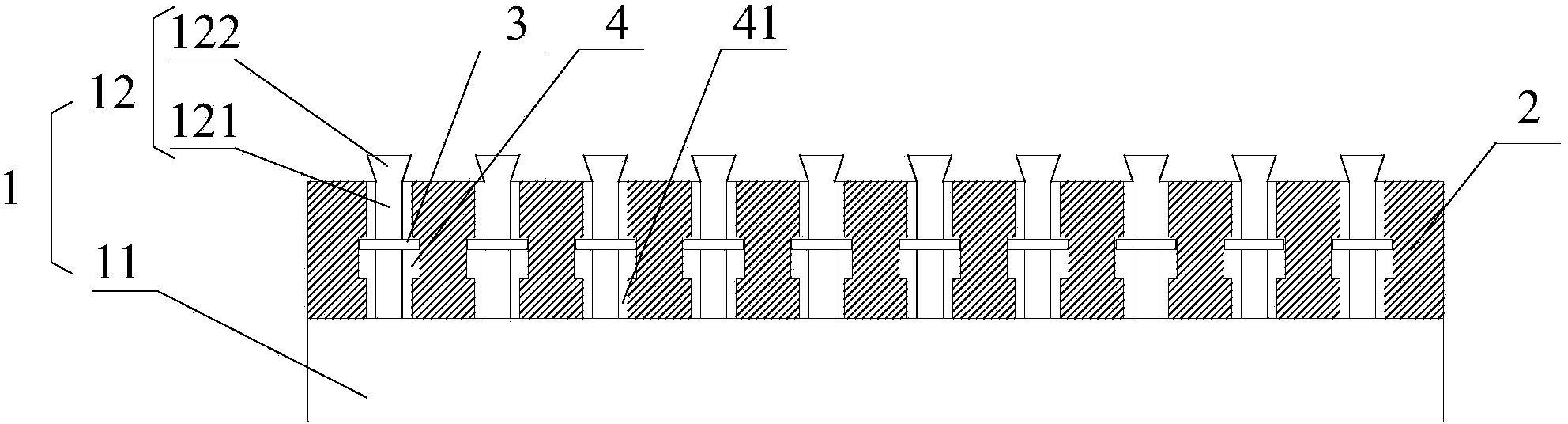

[0011] Such as figure 1 as shown, figure 1 It is a schematic structural diagram of a brake shoe assembly proposed by the present invention.

[0012] refer to figure 1 , in one embodiment, a brake shoe assembly proposed by the present invention is used to brake a vehicle by friction with a brake drum, including a brake shoe 1 and a friction lining 2, and the brake shoe 1 includes a brake body 11 and 10 connection parts 12 fixed on the side of the brake body 11 close to the friction lining 2, and the connection parts 12 are evenly distributed on the brake body 11. The connection parts 12 include a connecting rod body 121 and a friction end 122. The head 122 and the end of the connecting rod body 121 away from the brake body 11 are fixed. From the end away from the connecting rod body 121 to the end close to the connecting rod body 121, the cross-sectional area of the friction end 122 gradually decreases. The middle part of the connecting rod body 121 is provided with an annu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com