Precooling method and system of LNG unloading arm double-ball valve

A technology of unloading arm and double ball valve, applied in the field of LNG, which can solve the problems of LNG ship's heavy dependence and inapplicable pre-cooling test, and achieve the effect of flexible timing, simple structure and easy design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

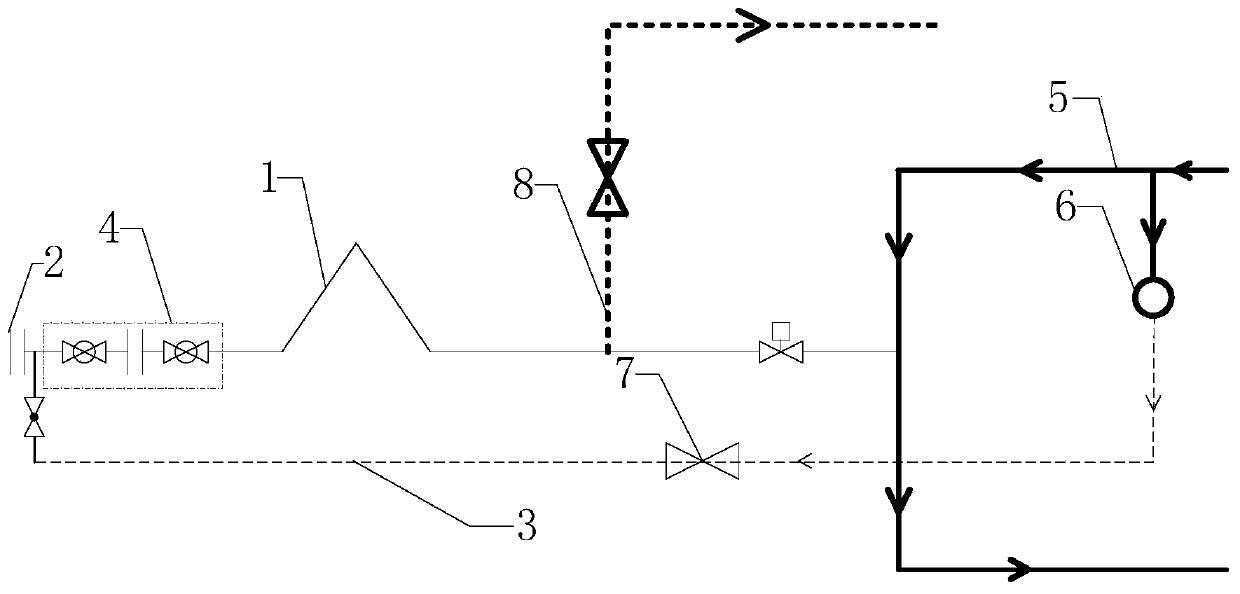

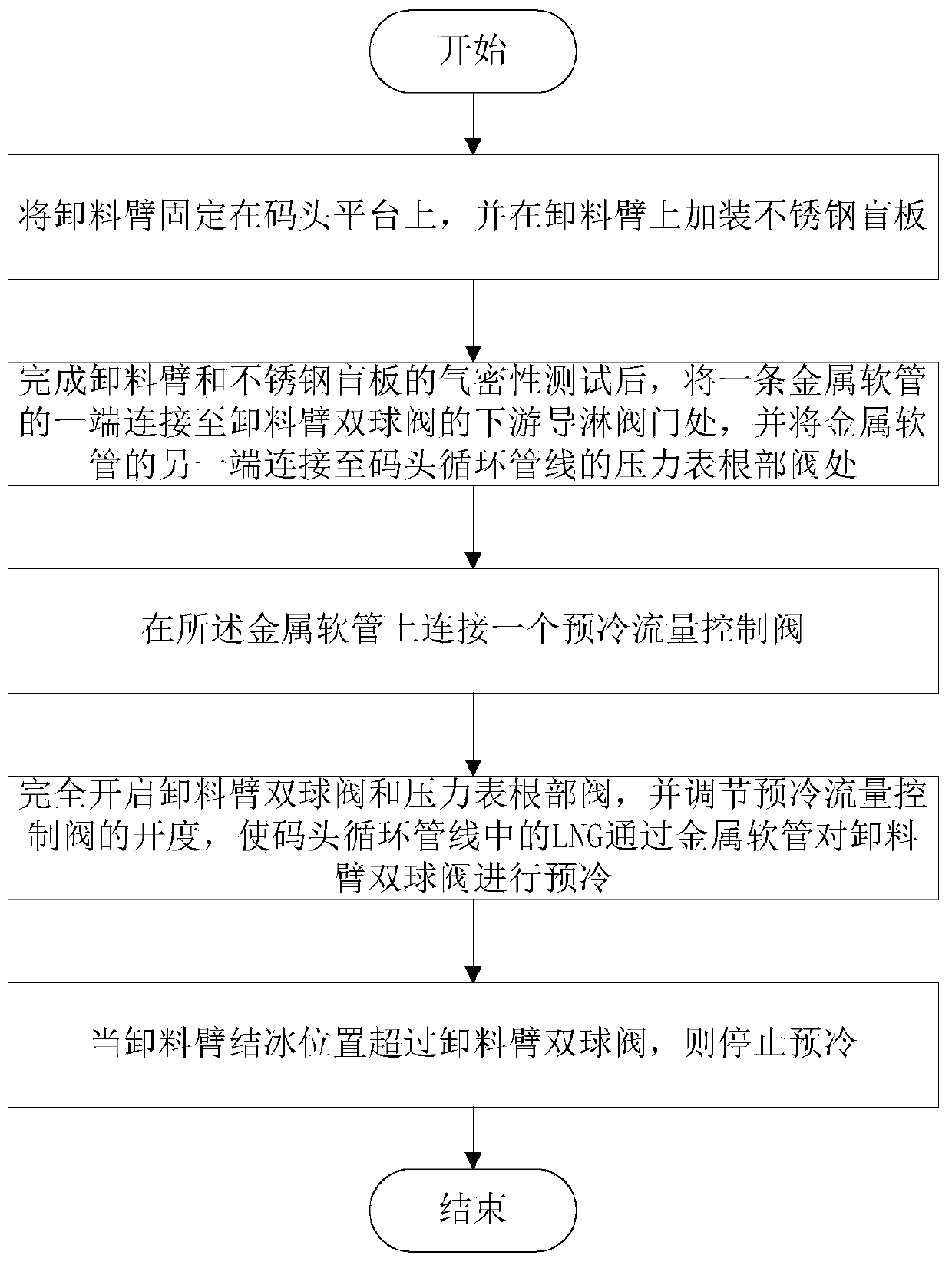

[0029] Such as figure 1 As shown, this embodiment provides a precooling system for a double ball valve of the LNG unloading arm, including a stainless steel blind plate 2 installed on the unloading arm 1, and the stainless steel blind plate is used to block the unloading arm 1 QCDC (QuickConnect / DisconnectCoupler, quick connection and disconnection between the unloading arm and the LNG ship) flange port; also includes a metal hose 3, and one end of the metal hose 3 is connected to the downstream guide of the double ball valve 4 of the unloading arm The other end is connected to the pressure gauge root valve 6 of the wharf circulation pipeline 5, and a pre-cooling flow control valve 7 is also arranged on the metal ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com