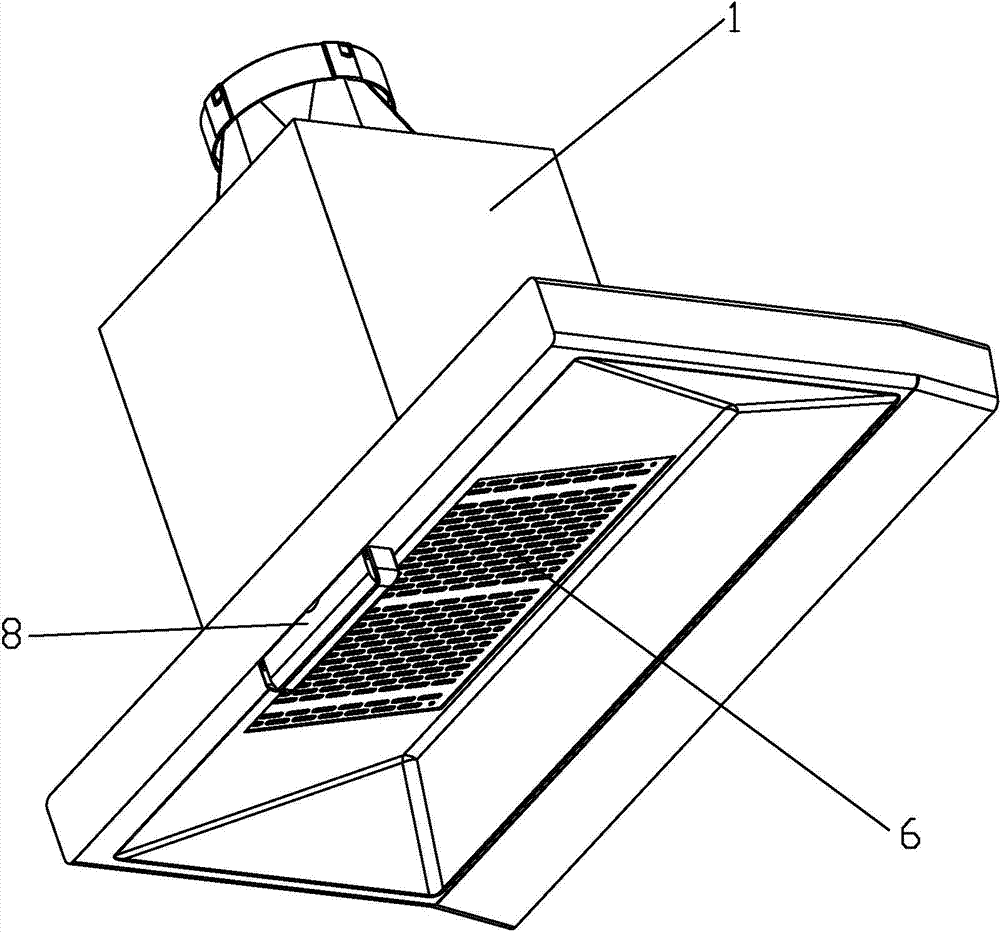

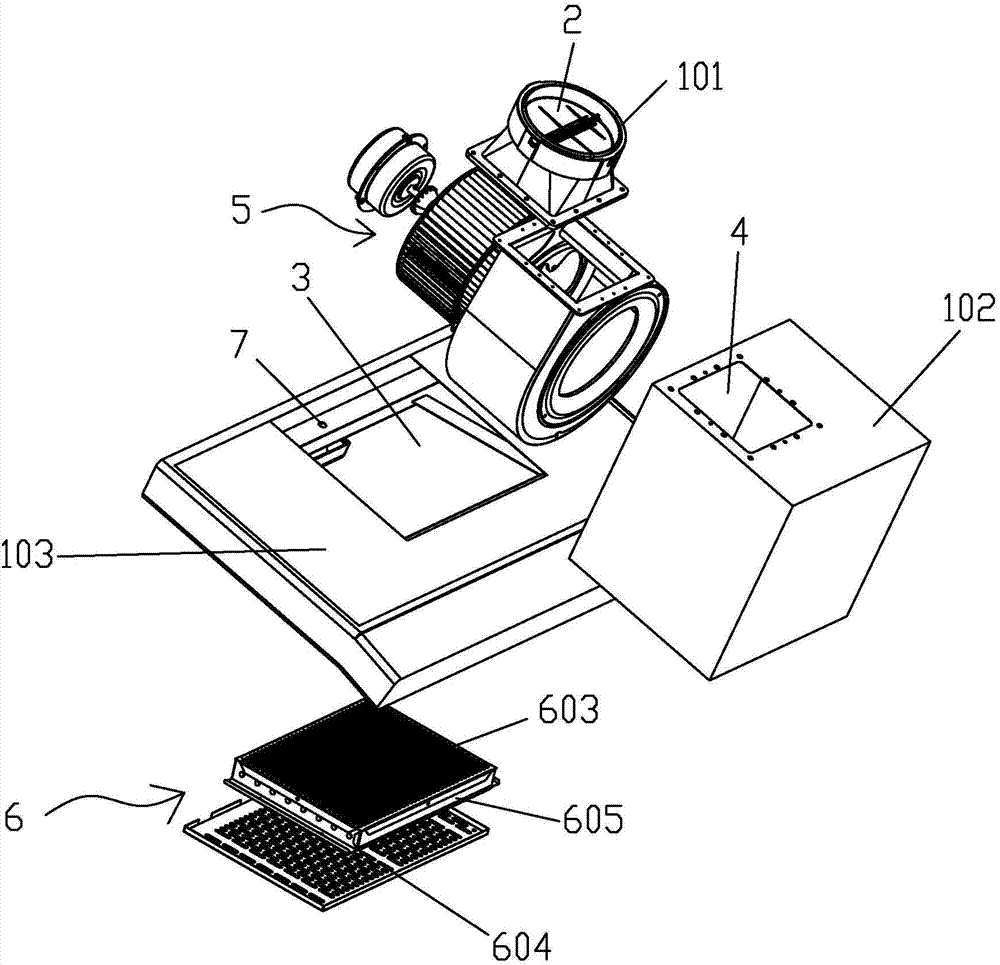

Range hood with oil fume separator

The technology of a range hood and a range hood is applied in the field of range hood, which can solve the problems of polluted environment, noise of range hood, poor operation, etc., and achieve the effects of reducing environmental pollution, prolonging service life and ensuring stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

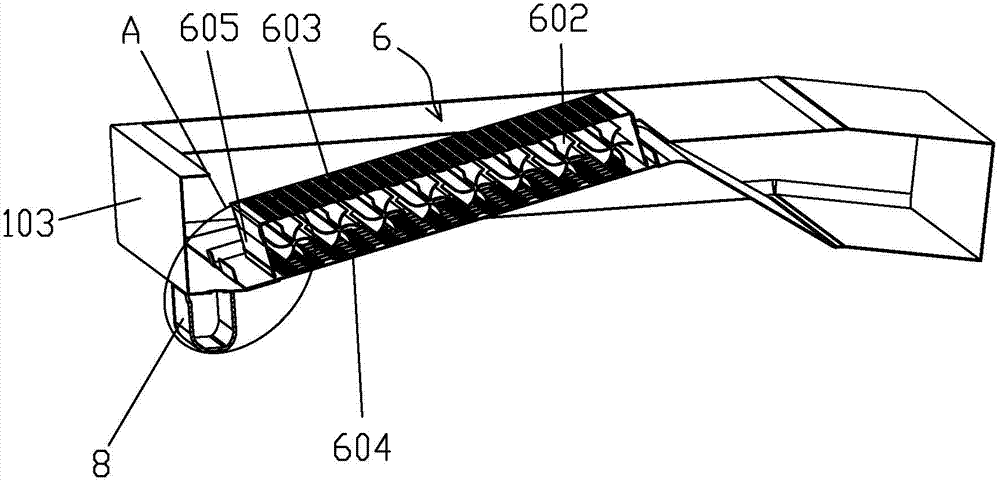

[0036] Embodiment 1: The rotating shaft 601 is provided with four condensation fins 602, the condensation fins 602 are vertically and symmetrically arranged on the plane, and the condensation fins 602 are made of aluminum alloy, such as Figure 4 shown.

Embodiment 2

[0037] Embodiment 2: The rotating shaft 601 is provided with four cooling fins 602, and the cooling fins 602 are symmetrically arranged on the rotating shaft 601 in a corrugated shape. The cooling fins 602 are made of stainless steel, such as Figure 5 shown.

Embodiment 3

[0038] Embodiment 3: The rotating shaft 601 is provided with four arc-shaped condensation fins 602, and the condensation fins 602 are arranged symmetrically in an arc-shaped plane. The condensation fins 602 are made of stainless steel, such as Image 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com