Multi-stage flash generating type heat source tower heat pump system and multi-stage regeneration method

A heat source tower heat pump, flash regeneration technology, applied in the field of air conditioning and refrigeration, can solve the problem of non-condensable gas degassing, high-temperature heat source driving heat reuse, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

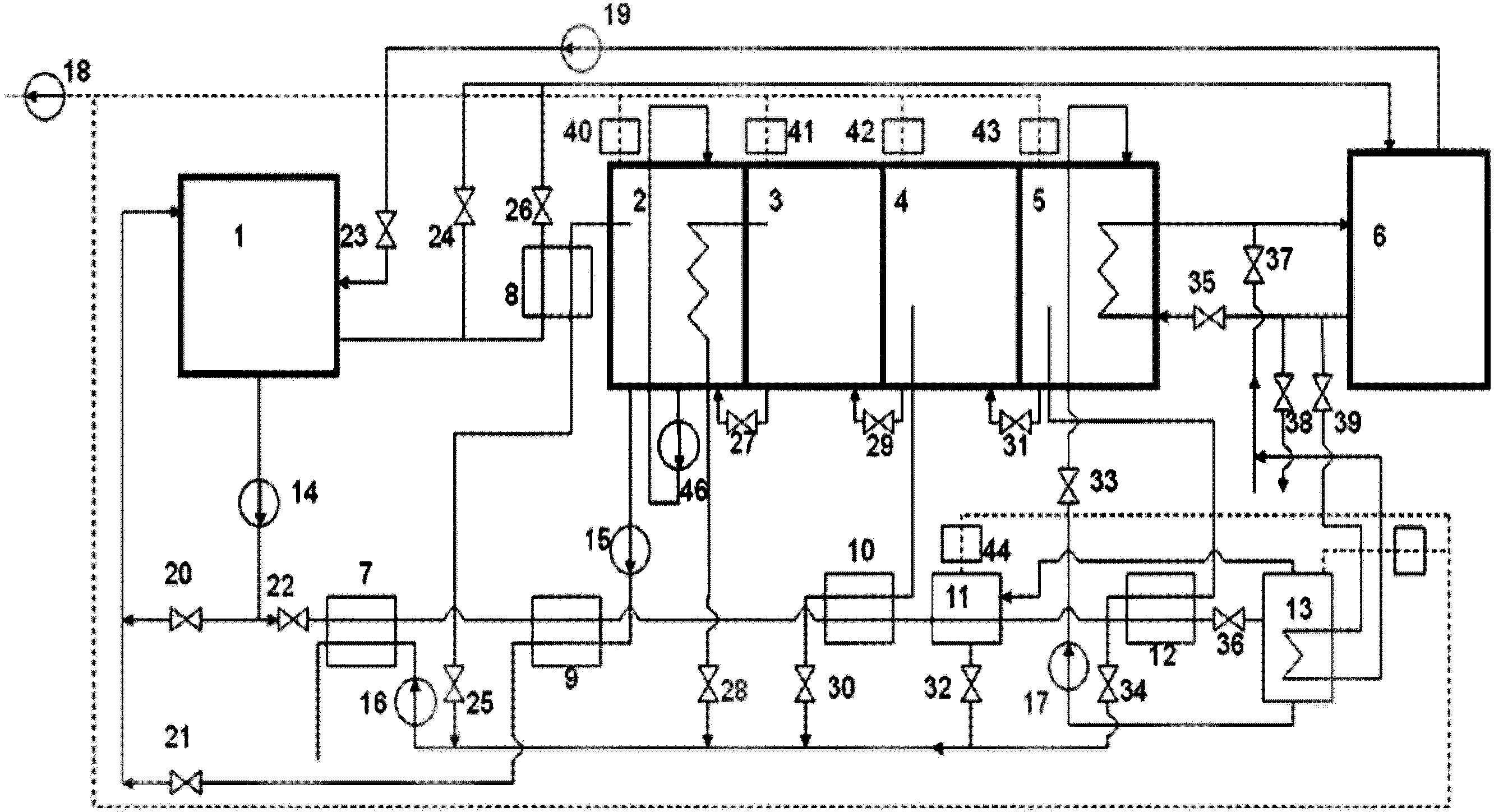

[0022] Embodiment 1, figure 1 A heat source tower heat pump system with multi-stage flash regeneration is given: it includes a working subsystem and a regeneration subsystem.

[0023] The working subsystem includes closed heat source tower 1, heat source tower circulation pump 14, bypass regulating valve 20, heat pump unit 6, organic organic solution circulation pump 19, inlet regulating valve 23, condenser bypass regulating valve 24, return water regulating valve 37 and a water supply regulating valve 38; the regenerative subsystem includes the fourth effect heat exchange chamber 2, the third effect heat exchange chamber 3, the second effect heat exchange chamber 4, the first effect heat exchange chamber 5, the condensation water heat exchanger 7, Condenser 8, solution heat exchanger 9, first heat exchanger 10, condensation degassing chamber 11, second heat exchanger 12, degassing chamber 13, outlet solution booster pump 15, condensed water pump 16, first effect exchanger Ho...

Embodiment 1

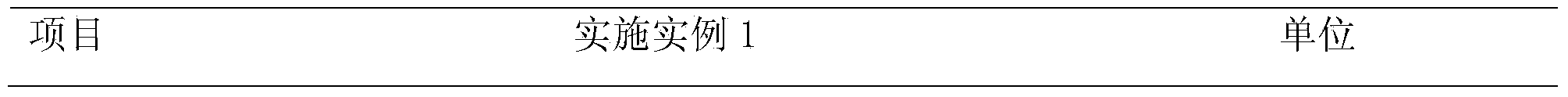

[0077] The calculation parameters of implementation example 1 are shown in Table 1 (for 1 kg of water vapor absorbed by the heat source tower heat pump system from the air), the system is in the regeneration mode under winter working conditions, and the design conditions are: ambient temperature 0 ° C, calcium chloride is used as the antifreeze solution solution, the mass concentration is 20%, the freezing point of antifreeze solution is -20°C, the temperature of hot water inlet and outlet is 45 / 40°C, 4-effect regeneration is adopted, the heat transfer temperature difference between effects is 3°C, and the minimum pressure of the system is 863.6pa (absolute pressure), the maximum pressure is the pressure of the first effect heat exchange chamber 4433pa, the exhausted steam in the degassing chamber accounts for 0.5% of the liquid intake, the condensing water temperature in the condensing and degassing chamber is 27°C, the condensation rate is 98.3%, and the vacuum pump in the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com