Cooling tower water spraying packing sheet

A technology of packing sheet and cooling tower, applied in the field of cooling tower packing, can solve the problems of equipment production process obstruction, short water film residence time, incomplete heat exchange, etc., and achieve significant heat exchange effect, prolong heat exchange time, and not easy to fall apart. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with drawings and embodiments.

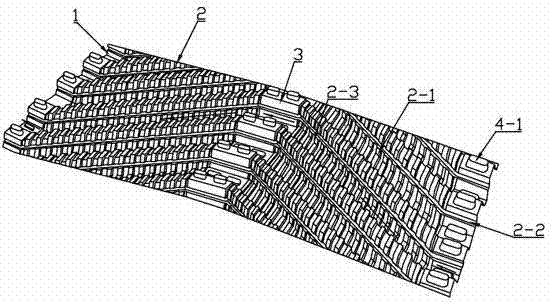

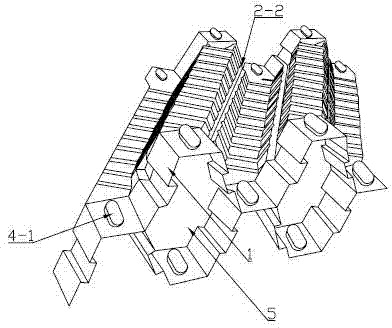

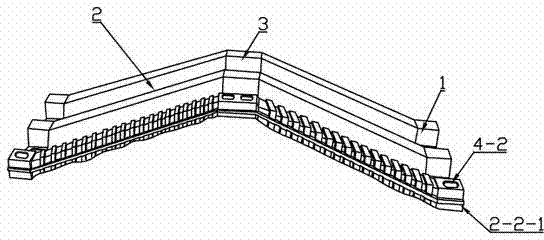

[0012] Such as figure 1 and figure 2 As shown, the present invention includes a filler sheet body. The filler sheet body includes a water shower plate 2 with a trapezoidal cross section and an adhesive edge 1 . The adhesive edge 1 is arranged on both sides of the water shower plate 2 . A running water tank 2-2 is arranged on the trapezoidal waist.

[0013] Such as figure 1 and image 3 As shown, the running water groove 2-2 on one side of the trapezoidal waist has a flowing water groove structure, and the other side corresponding to the trapezoidal waist has a flowing water convex strip structure 2-2-1. The design of the flow tank 2-2 can evenly distribute the cooling water, avoiding the concentration of the cooling water in the stagnation area, and making the heat exchange effect more remarkable. When the front of the packing sheet body is a water flow groove str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com