Automobile generator rotor assembling technology

An automobile generator and rotor assembly technology, which is applied in the manufacture of stator/rotor body, etc., can solve the problems of easy damage and cracking of fan blades and retaining rings, low knurling depth, and difficulty in pressing and fitting, so as to solve the problems of easy falling apart , Simple alignment, firm and stable assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

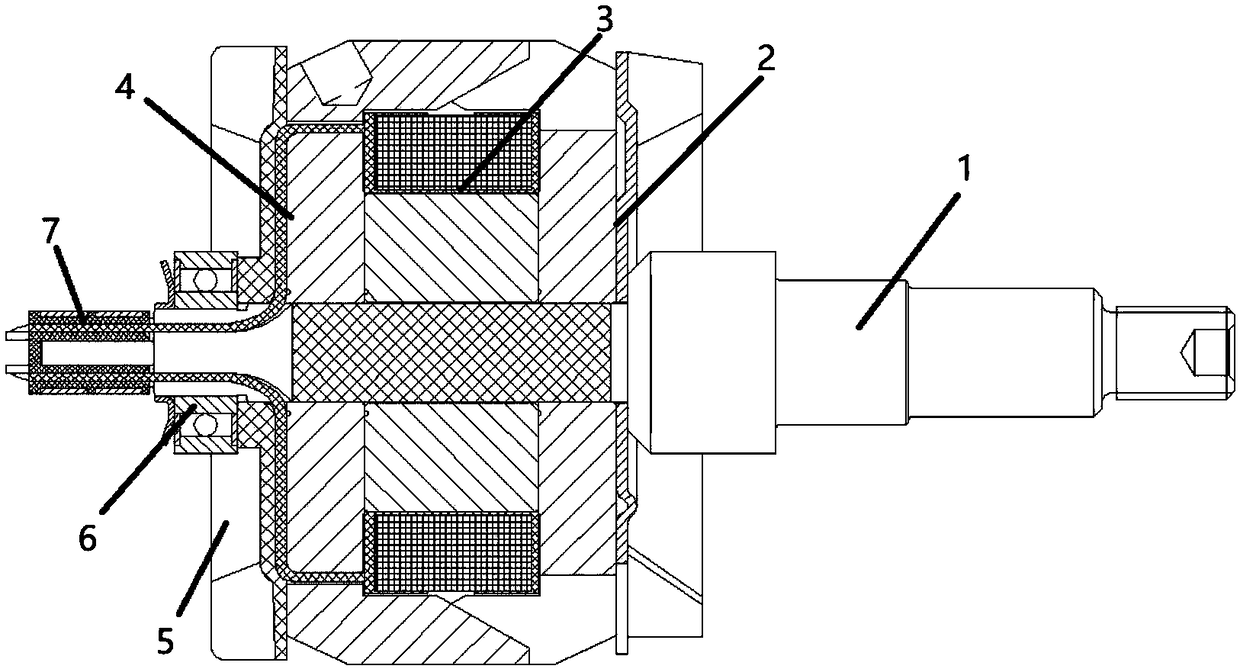

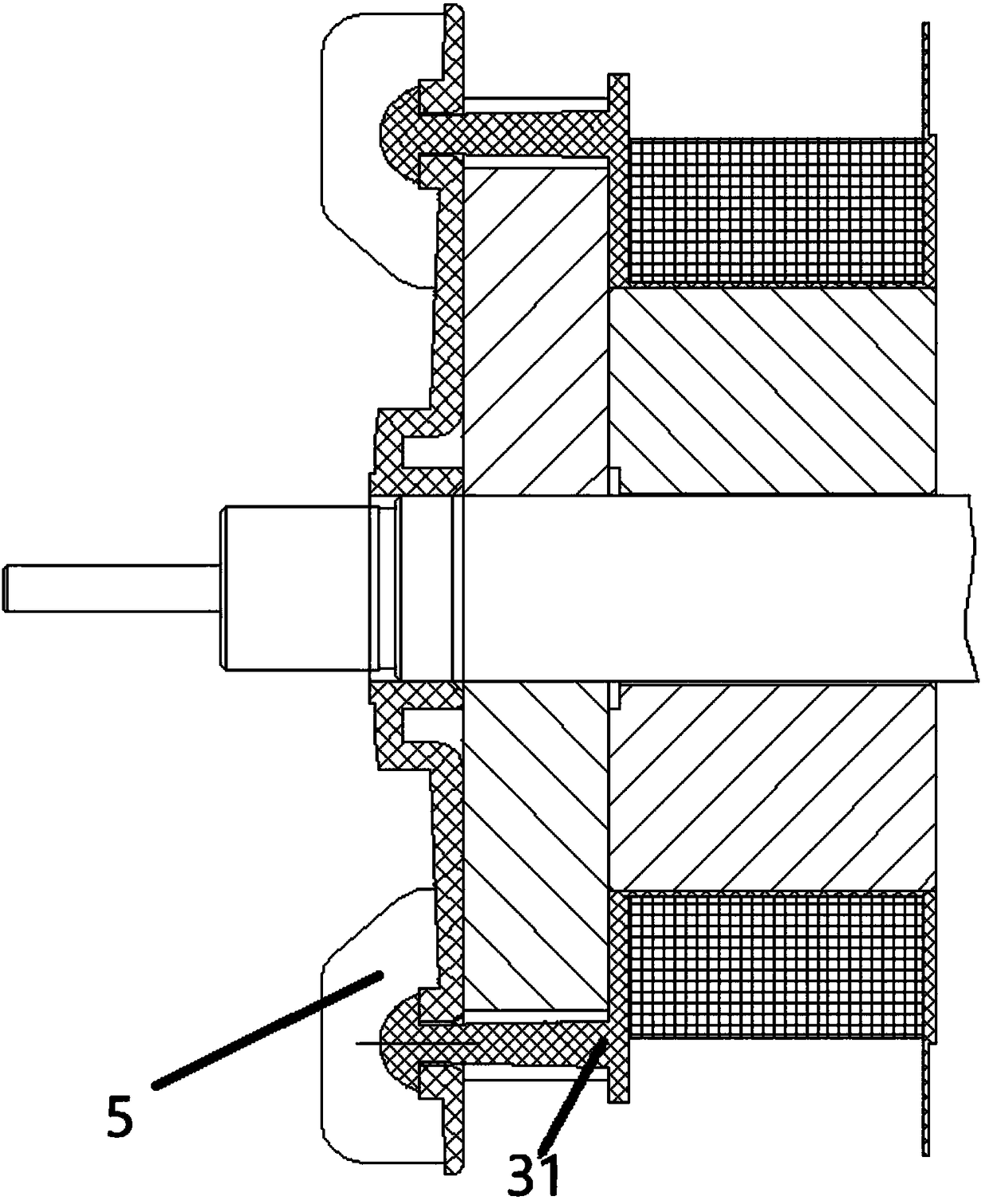

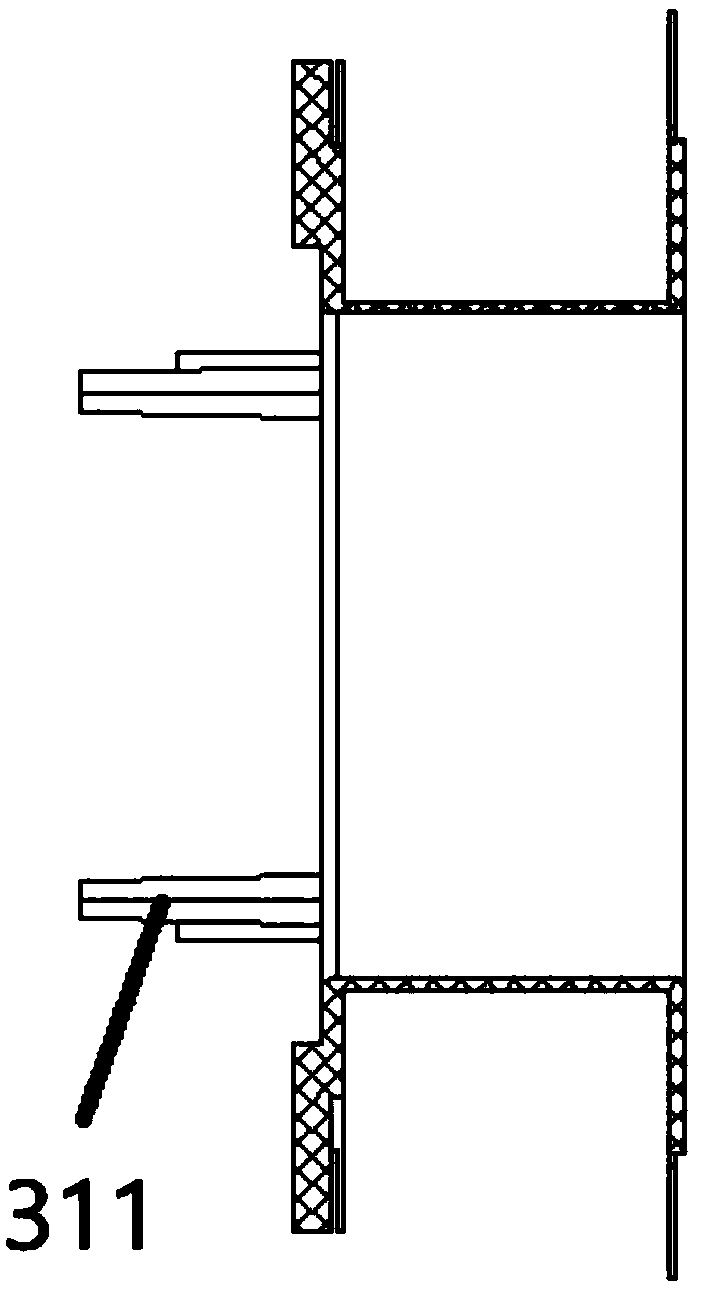

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0033] Such as Figure 1-Figure 4 As shown, the present invention schematically shows an assembly process of an automobile generator rotor.

[0034] The invention discloses an assembly process of an automobile generator rotor, which is characterized in that it comprises the following steps:

[0035] Step 1: Make an indenter according to the diameter of the rotor main shaft 1. Further, the shape of the indenter is tubular, the inner diameter of the indenter is larger than the outer diameter of the rotor main shaft 1, and one end is provided with an annular pointed boss. On the one hand, it avoids the interference between the rotor main shaft 1 and the indenter; on the other hand, it can effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com