Circuit of Ferromagnetic Coating Thickness Gauge Based on Mobile Display Terminal

A technology of display terminal and thickness gauge, which is applied in the field of ferromagnetic coating thickness gauge circuit, can solve the problems of limited data processing capability, low resolution, and high cost, so as to achieve strong data processing capability and improve instrument performance. , The effect of reducing the cost of the instrument

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

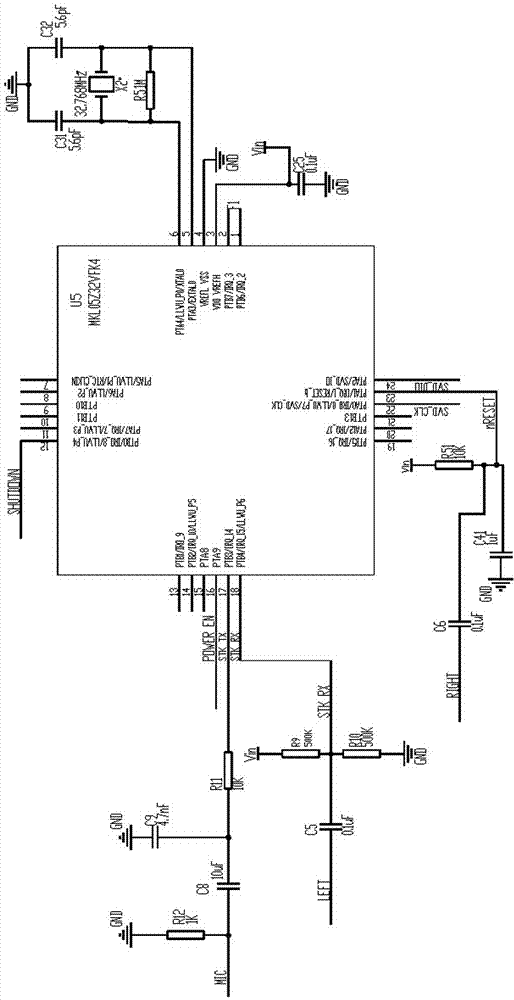

[0030] For the convenience of description, the circuit of the inventive ferromagnetic coating thickness gauge based on the mobile display terminal will be described in detail below in conjunction with the accompanying drawings.

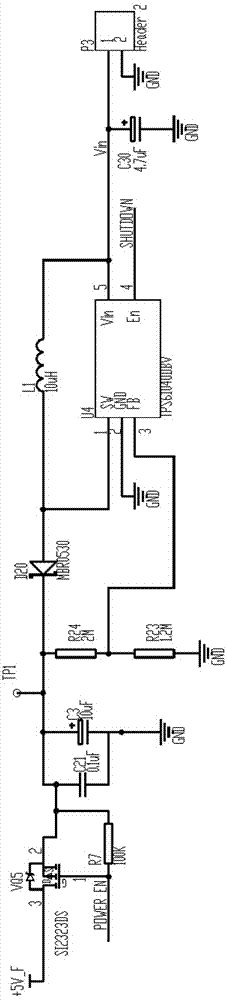

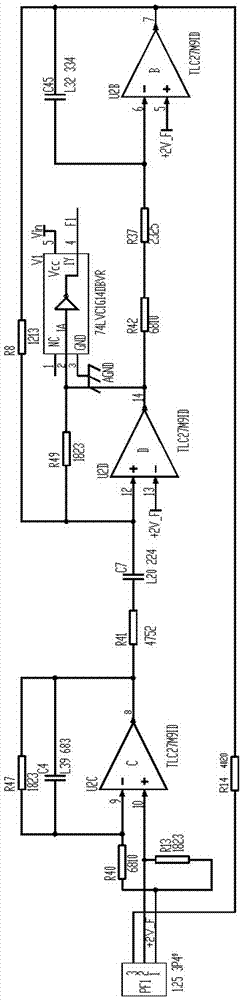

[0031] Such as Figure 1 to Figure 5 As shown in , a ferromagnetic coating thickness gauge circuit based on a mobile display terminal, including F-type coating probe, audio plug, 3-core cable, data acquisition and coding modulation circuit module.

[0032] The data acquisition and coding modulation circuit module includes a data processing circuit.

[0033] In the ferromagnetic coating thickness gauge circuit based on a mobile display terminal, the data processing circuit includes a U5 microcontroller of the model MKL05Z32VFK4, and the U5 microcontroller includes numbers 1 to 24, a total of 24 wiring foot;

[0034] Terminal 1 is PTB6 / IRQ_2, and terminal 1 is connected to F1.

[0035] Pin No. 2 is the PTB7 / IRQ_3 terminal, and pin No. 2 is vacant;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com