Measurement device for strain characteristics of material under extreme conditions

A measuring device and a technology for extreme conditions, applied in the field of measuring devices, can solve problems such as the measurement function of strain characteristics under multi-physical fields, and achieve the effects of reliable measuring method, good repeatability and simple structure of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

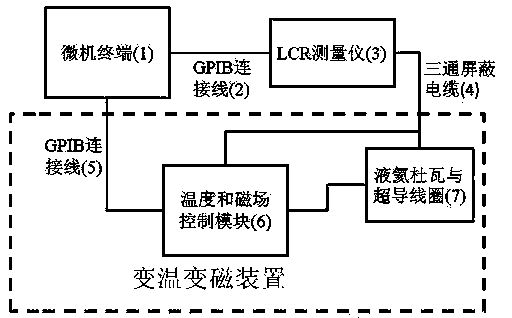

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

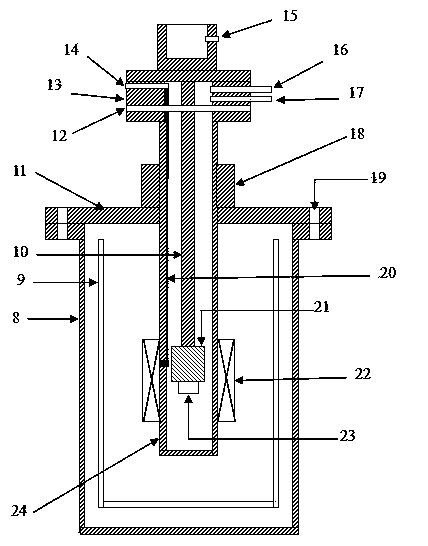

[0029] Preferred embodiment of the present invention is described in detail with reference to accompanying drawing as follows:

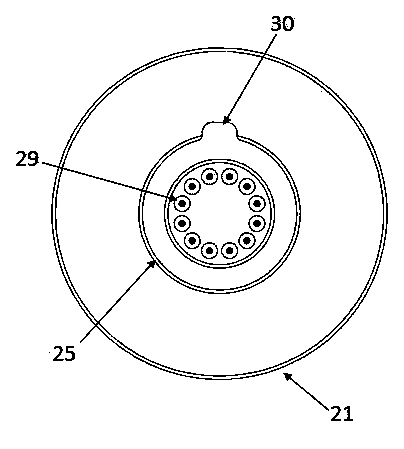

[0030] A measuring device for strain characteristics of materials under extreme conditions, including a microcomputer terminal 1, a TDS-150 data acquisition instrument 3, a temperature-variable magnetic device and a Dewar sleeve inside, a cryogenic chamber 24, a sample conduit 10, and a Dewar cover 11. Superconducting coil 22 , sample stage joint 21 and sample stage 23 .

[0031] The Dewar cover 11 is sealedly installed on the upper end surface of the Dewar sleeve through the first flange to form an outer cavity, and the Dewar bottle 9 is located in the outer cavity; a through hole is opened in the center of the Dewar cover, and the low temperature cavity The lower end of 24 is embedded in the through hole of the Dewar cover 11 and is located in the Dewar bottle 9; the vacuum module 13 is located at the upper end of the low temperature cavity 24, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com