Antenna tower structure virtual assembly method based on scene visualization

A technology of virtual assembly and antenna tower, applied in special data processing applications, instruments, electrical digital data processing, etc., to achieve the effect of broad application prospects and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

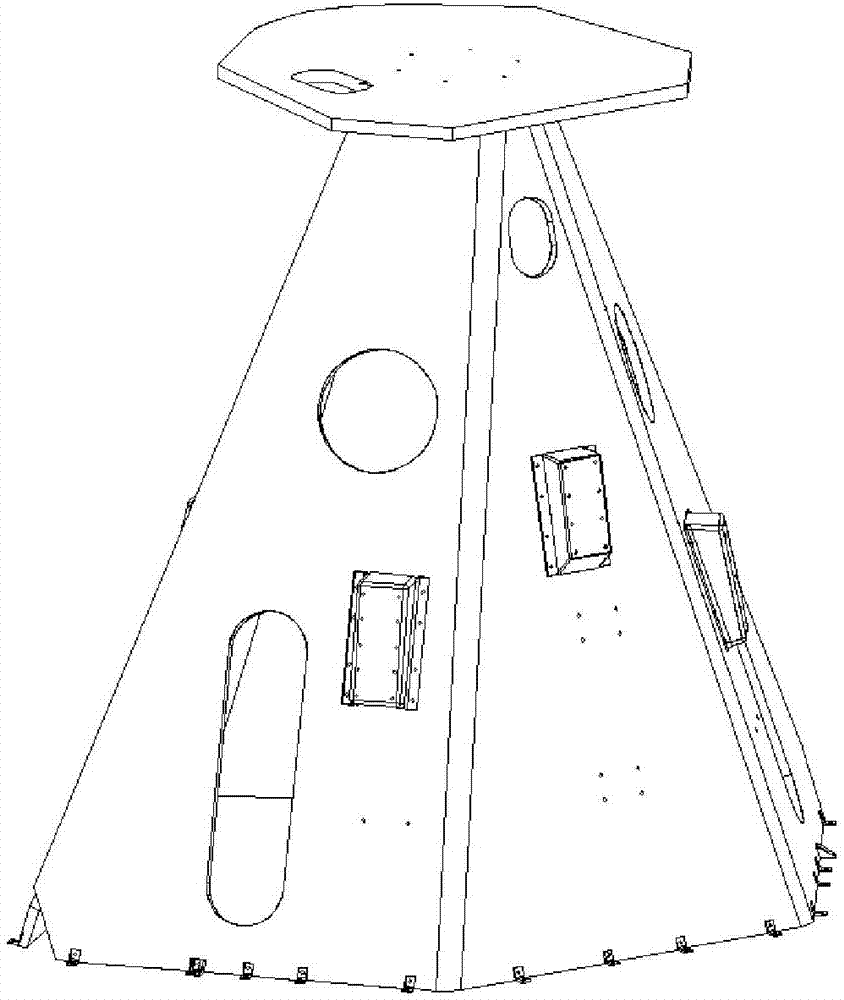

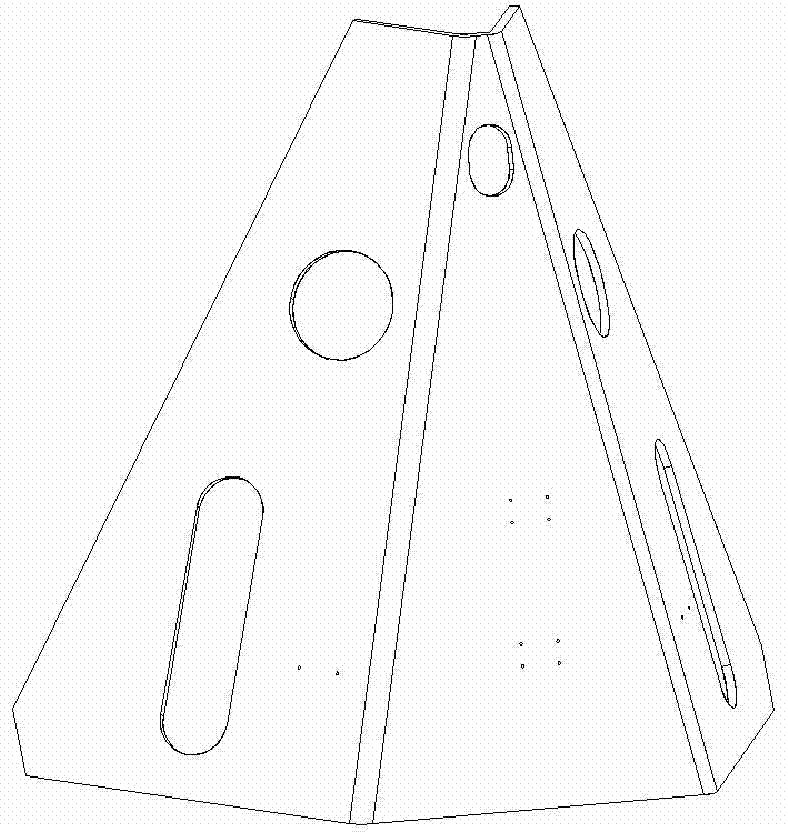

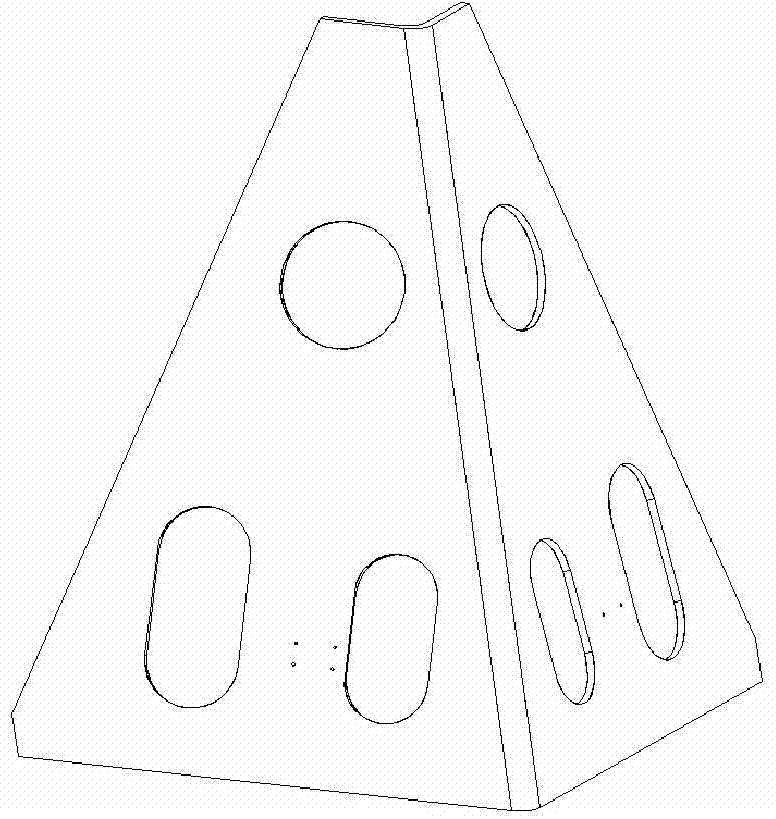

[0023] In the structure of a certain type of satellite antenna tower in my country (as attached Figure 1a ) in the structural assembly, the accuracy of product assembly can be well guaranteed by using the present invention. The antenna tower structure consists of a structural plate consisting of three fixed faces (e.g. Figure 1b shown), a structural plate consisting of two fixed surfaces (such as Figure 1c As shown), the two structural plates are assembled to form a five-sided tower body support plate, and a top plate is installed on the tower body support plate,

[0024] attached figure 2 Shown is the payload support assembled on the tower body. The ultimate purpose of adjusting the structure of the antenna tower body is to ensure the installation accuracy of the payload support.

[0025] The following introduces the application of this technology in actual assembly, specifically divided into two cases: the embedded parts at the installation place of the payload support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com