LED substrate structure and manufacturing method of LED substrate structure

A technology of substrate structure and manufacturing method, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of low light output efficiency of LEDs, and achieve the effects of increasing light output efficiency, increasing axial luminous brightness, and improving luminous brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

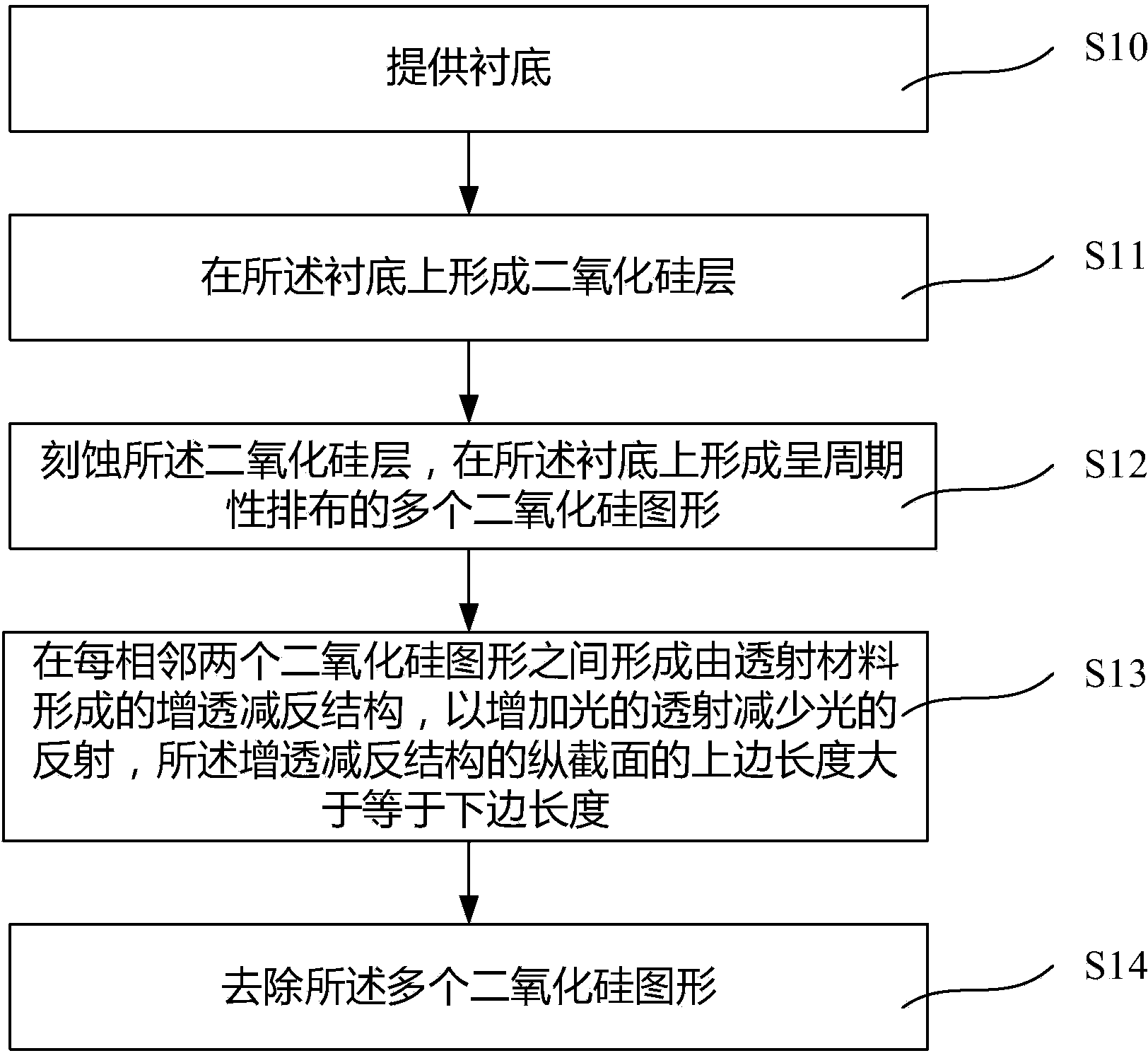

[0051] Specifically, please refer to Figure 2 to Figure 12 , which is a schematic diagram of a device structure formed in the method for manufacturing an LED substrate structure according to Embodiment 1 of the present invention.

[0052] Such as figure 2 As shown, a substrate 20 is provided, preferably, the substrate 20 is a sapphire substrate.

[0053] Next, if image 3 As shown, a silicon dioxide layer 21 is formed on the substrate 20 . In the embodiment of the present application, the thickness of the silicon dioxide layer 21 is 0.5 micrometers to 3 micrometers. Preferably, in forming the silicon dioxide layer 21 on the substrate 20, the deposition speed of the silicon dioxide layer 21 becomes slower and slower, and the process temperature becomes higher and higher. Preferably, the deposition rate of the silicon dioxide layer 21 is gradually decreasing from 100 angstrom / sec to 10 angstrom / sec, and the process temperature is gradually increasing from 200°C to 800°C. ...

Embodiment 2

[0071] Specifically, please refer to Figure 13 to Figure 20 , which is a schematic diagram of the device structure formed in the method for manufacturing the LED substrate structure according to the second embodiment of the present invention.

[0072] Such as Figure 13 As shown, a substrate 30 is provided, preferably, the substrate 30 is a sapphire substrate.

[0073] Next, if Figure 14 As shown, a silicon dioxide layer 31 is formed on the substrate 30 . In the embodiment of the present application, the thickness of the silicon dioxide layer 31 is 0.5 micrometers to 3 micrometers. Preferably, in forming the silicon dioxide layer 31 on the substrate 30, the deposition speed of the silicon dioxide layer 31 becomes slower and slower, and the process temperature becomes higher and higher. Preferably, the deposition rate of the silicon dioxide layer 31 is gradually decreasing from 100 angstrom / sec to 10 angstrom / sec, and the process temperature is gradually increasing from 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com