Three-level wave-by-wave current limiting control method and system

A wave-by-wave current limiting and control method technology, applied to electrical components, AC power input conversion to DC power output, output power conversion devices, etc., can solve large voltage difference, reduce the quality of current waveform, and three-level inverter The problem of small inductance of the reactor and the reactor is eliminated, and the output current is smooth and the quality of the current waveform is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

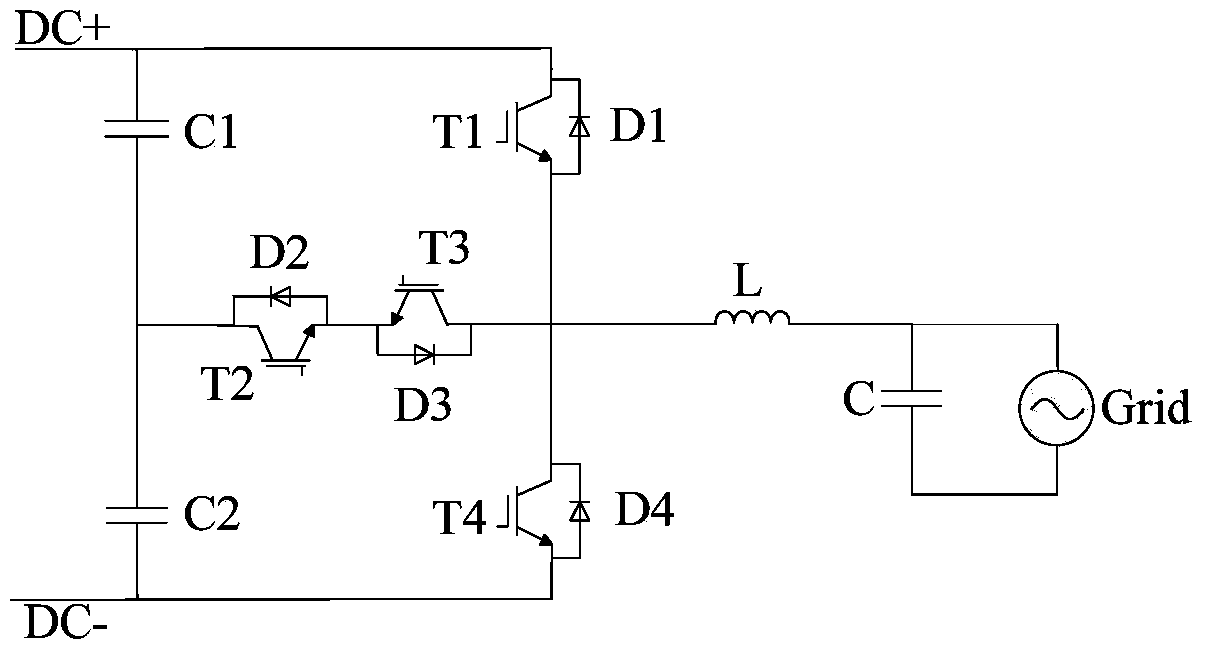

Embodiment 1

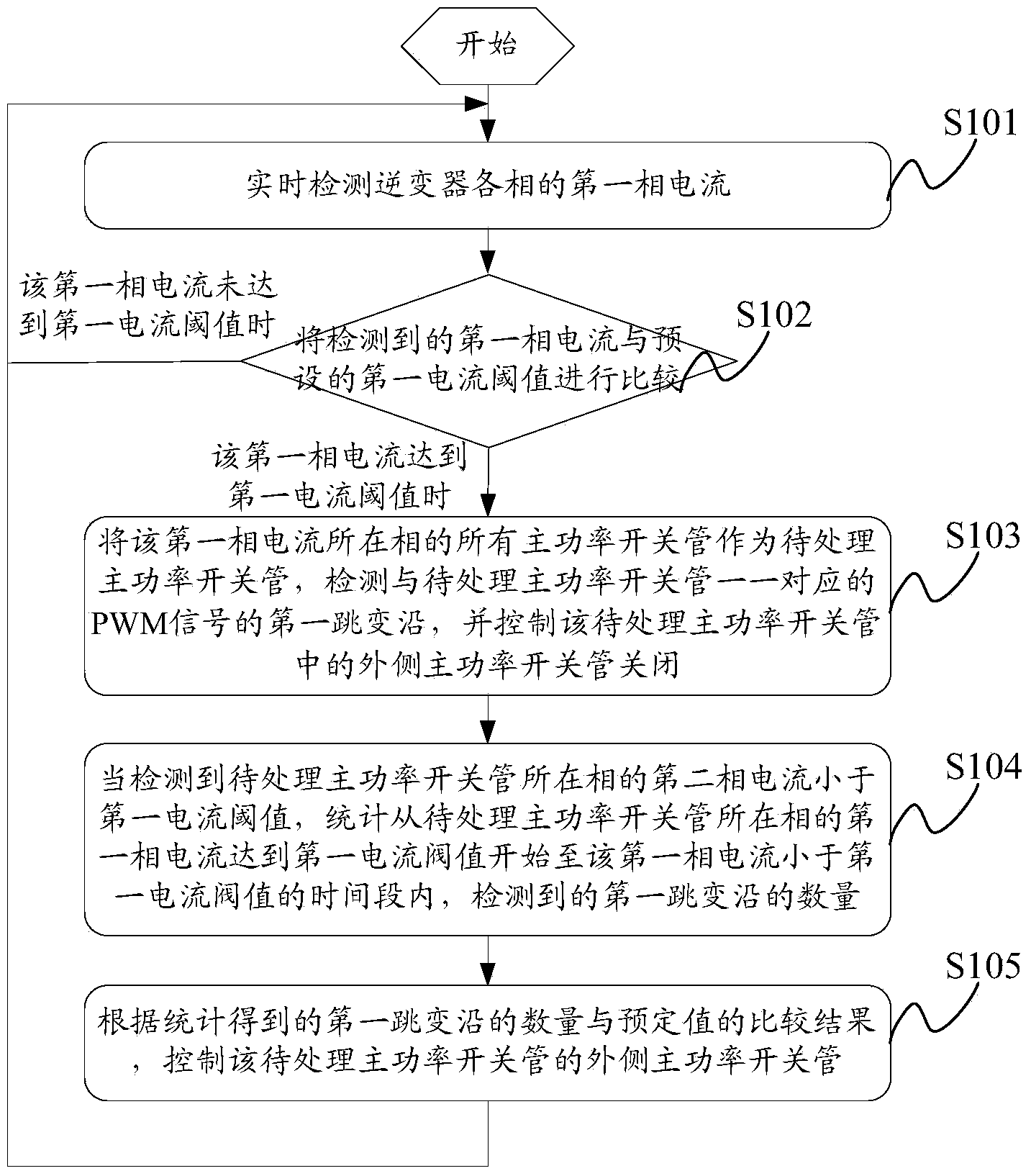

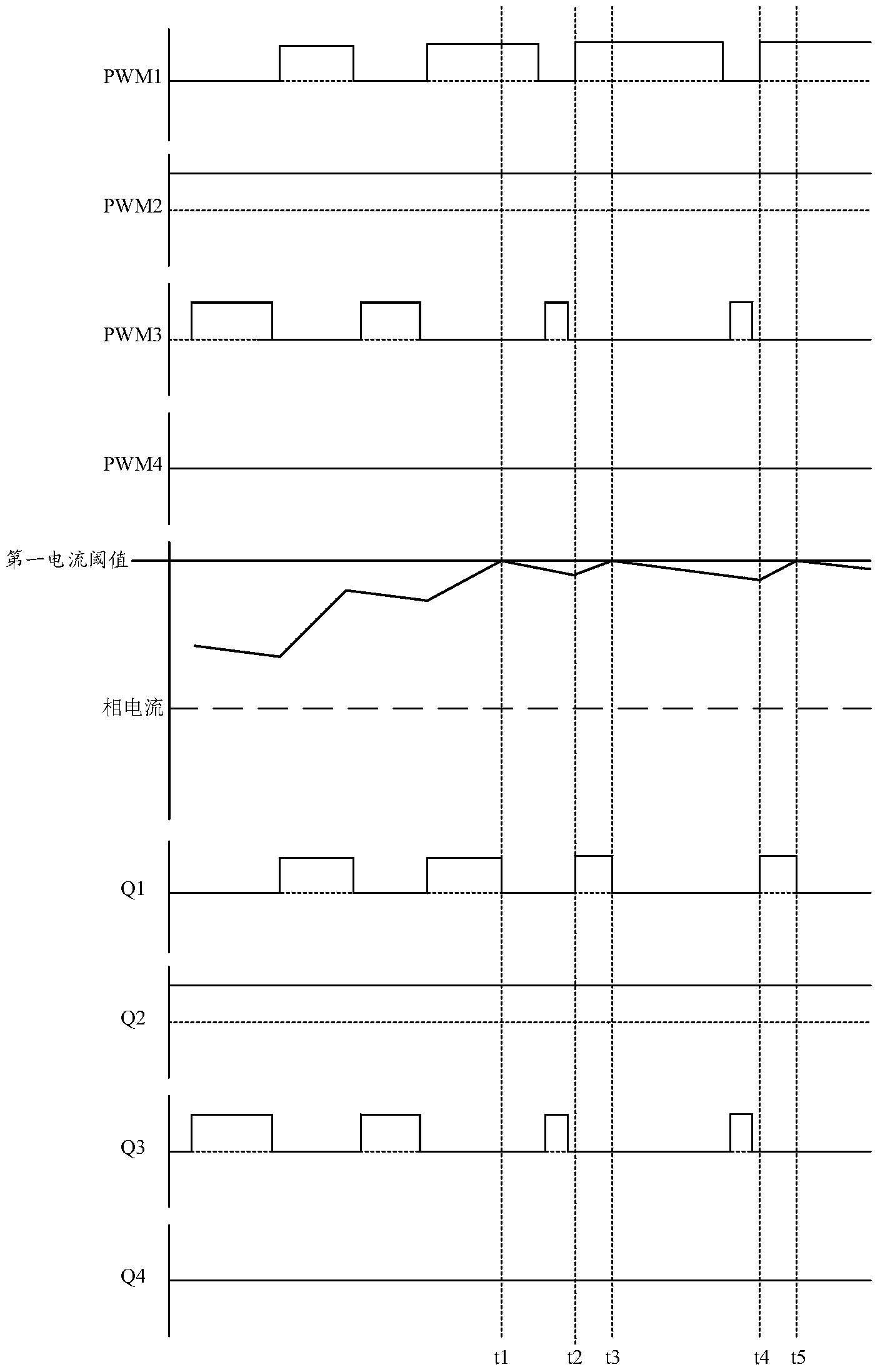

[0056] Such as figure 2 As shown, it is a schematic flow chart of an embodiment of a three-level wave-by-wave current limiting control method of the present invention, combined with image 3 The timing diagram of the three-level wave-by-wave current limiting control method shown in the embodiment of the present invention, the control method may include the following steps:

[0057] Step S101: Real-time detection of the first phase current of each phase of the inverter.

[0058] In practical applications, the current detection circuit in the system can be used to detect the current current of each phase of the system, that is, the first phase current, so as to subsequently determine whether the inverter has overcurrent based on this. Wherein, the number of current detection circuits in this embodiment may depend on the output phases of the system. For a three-phase inverter, three current detection circuits are required to detect the overcurrent signals of the phases respecti...

Embodiment 2

[0080] Such as Figure 5 As shown, it is a schematic flow chart of another embodiment of the three-level wave-by-wave current limiting control method of the present invention, and the method may include the following steps:

[0081] Step S201: Real-time detection of the first phase current of each phase of the inverter.

[0082] Step S202: Compare the first phase current with preset first current threshold and second current threshold respectively.

[0083] Wherein, when the first phase current is less than the first current threshold value, it means that the inverter does not have overcurrent, and it will return to step S201 to continue execution.

[0084] Step S203: When the first phase current is greater than the first current threshold and less than the second current threshold, use all the main power switching tubes of the phase where the first phase current is located as the main power switching tubes to be processed, and detect the Processing the rising edges of the P...

Embodiment 3

[0099] Such as Figure 7 As shown, it is a schematic structural diagram of an embodiment of a three-level wave-by-wave current limiting control system embodiment of the present invention, and the system may include:

[0100] The DSP chip 301, the wave-by-wave current limiting processing device 302, the main power drive circuit 303 and the main power circuit 304 connected in sequence, and the first overcurrent signal judging circuit 305 connected with the wave-by-wave current limiting processing device 302 are connected with the The current detection circuit 306 connected to the first overcurrent signal judging device 305 is respectively connected to the port corresponding to the outer power switch tube of the main power circuit 304 in the DSP chip 301, and the wave-by-wave current limiting processing device 302 The connected PWM signal detection device 307, wherein:

[0101] The DSP chip 301 is used to generate PWM signals corresponding one-to-one to the main power switch tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com