Blighted grain separator

A technology of separators and grains, applied in the direction of solid separation, separating solids from solids with airflow, chemical instruments and methods, etc., to achieve the effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

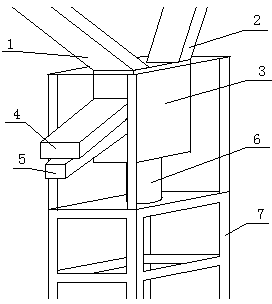

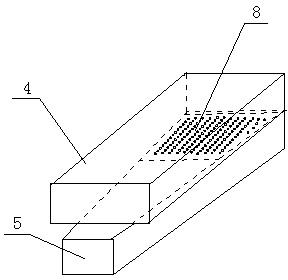

[0020] Such as figure 1 and figure 2 As shown, the present embodiment provides a kind of grain separator, including air blower, wind pipe 1, feed pipeline 2, separation bin 3, the first discharge hopper 4 for conveying the separated grain, for conveying and separating The second discharge hopper 5 and the discharge pipeline 6 for removing impurities, one end of the air-initiating pipeline 1 is connected to the air outlet of the blower, the other end of the air-initiating pipeline 1 is connected to the separation chamber 3, and the top of the separation chamber 3 is connected to The feed pipe 2, the bottom of the separation bin 3 is connected to the discharge pipe 6, and the side of the separation bin 3 is connected to the first discharge hopper 4 and the second discharge hopper 5 in sequence. The discharge pipeline 6 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com