Electrolytic machining method for blisk through oblique swinging mode of spatial swivel feeding composite workpiece

A technology of spatial rotation and integral blisk, applied in electric machining equipment, electrochemical machining equipment, metal machining equipment, etc., to achieve the effect of wide application, optimized feed path, and reduced machining allowance difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

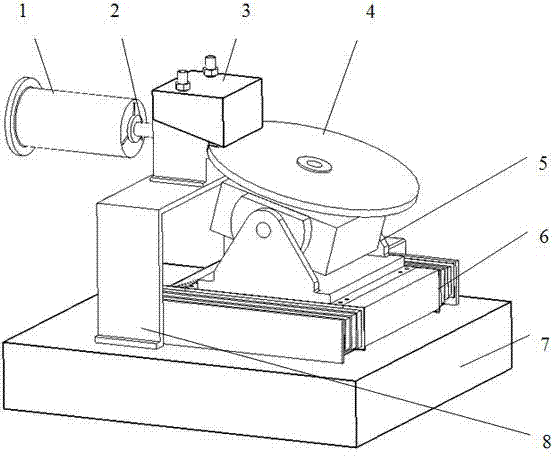

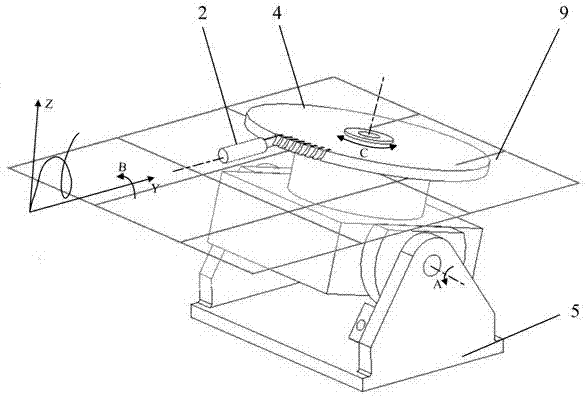

[0018] Combine below figure 1 , 2 , illustrate the specific implementation process of the present invention:

[0019] 1. Reference figure 1 , using a six-axis CNC high-efficiency electrolytic machining machine tool with complex profiles, the machine tool includes a base, a reference platform 7 installed on the base, a Y linear motion platform installed on the reference platform 7, an X linear motion platform and a fixture reference 8; Install the column on the ram of the motion platform, install the Z linear motion platform on the column, install the Y direction CNC turntable on the ram of the Z linear motion platform, install the output shaft 1 on the Y direction CNC turntable, and install it between the Y direction CNC turntable and the output shaft 1 Install the first insulating pad; the Y-direction CNC turntable and the counterweight bracket of the output shaft 1 are installed on the column; the Z-direction rotation and X-direction tilting CNC turntable 5 are installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com