Complex surface numerical control efficient electrolytic machining tool

A technology of electrolytic processing machine tools and complex profiles, which is applied in the direction of electrochemical processing equipment, metal processing equipment, manufacturing tools, etc., which can solve the problems of poor surface quality, low machining accuracy of cascade channel hubs, etc., and reduce the machining allowance Poor, improve machining accuracy and surface quality, reduce the effect of margin difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

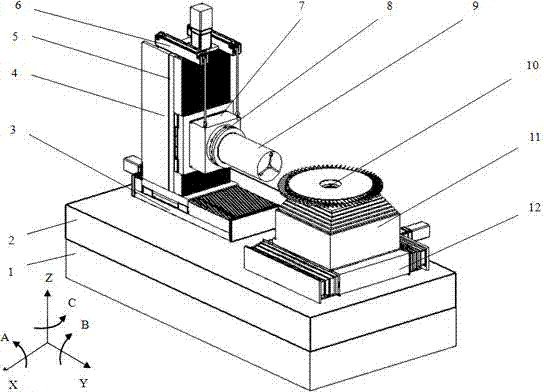

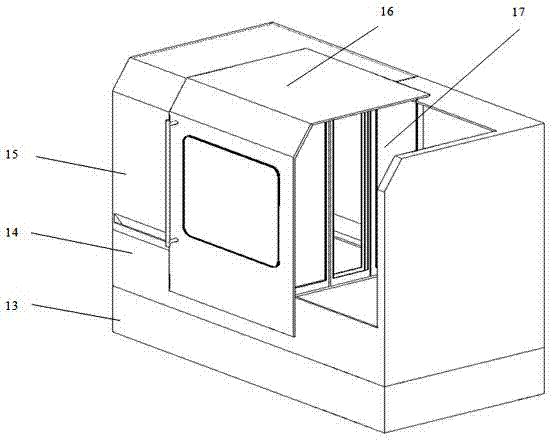

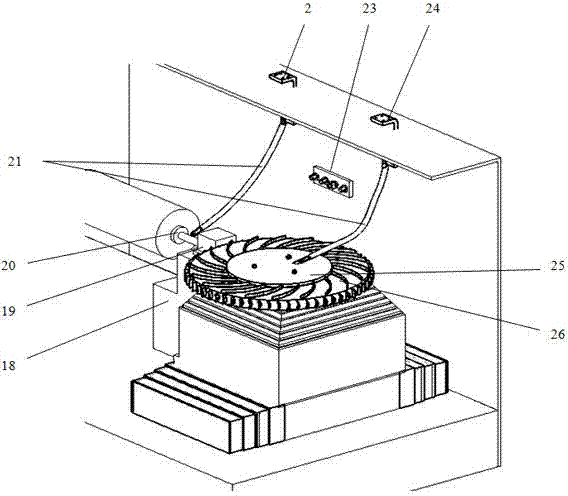

[0030] Combine below figure 1 , 2 , 3, illustrate the specific implementation process of the present invention:

[0031] 1. Reference figure 1 , the base 1 is placed on the ground through level adjustment feet, and the reference platform 2 is installed on the base 1 . The reference platform 2 is divided into two areas: the left non-processing area and the right processing area.

[0032] 2. Reference figure 1 , in the left non-processing area, the Y linear motion platform 3 is installed on the reference platform 2, the column 4 is installed on the ram of the Y linear motion platform 3, and the Z linear motion platform 5 is installed on the column 4. A Y-direction digital control turntable 7 is installed on the ram of the Z linear motion platform 5 , the output end 9 is installed on the Y-direction numerical control turntable 7 , and a first insulating pad 8 is installed between the Y-direction numerical control turntable 7 and the output end 9 . The counterweight bracket 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com