Sheet stock slitting machine

A slitting machine and sheet material technology, which is applied to the attachment of shearing machines, knives for shearing machine devices, shearing devices, etc., can solve the problem that it is difficult to form straight edges, crooked, and affect production efficiency. problem, to achieve the effect of smooth cutting process, preventing wrinkling and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be further described in detail below in conjunction with specific embodiments.

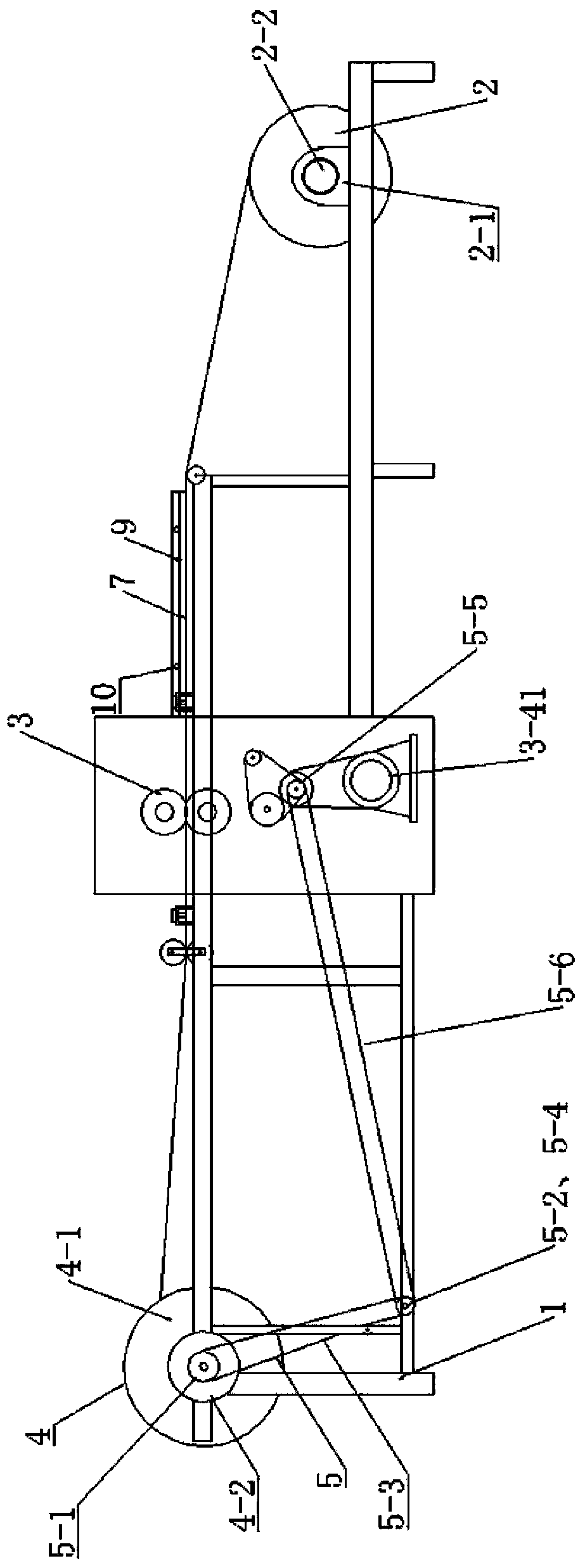

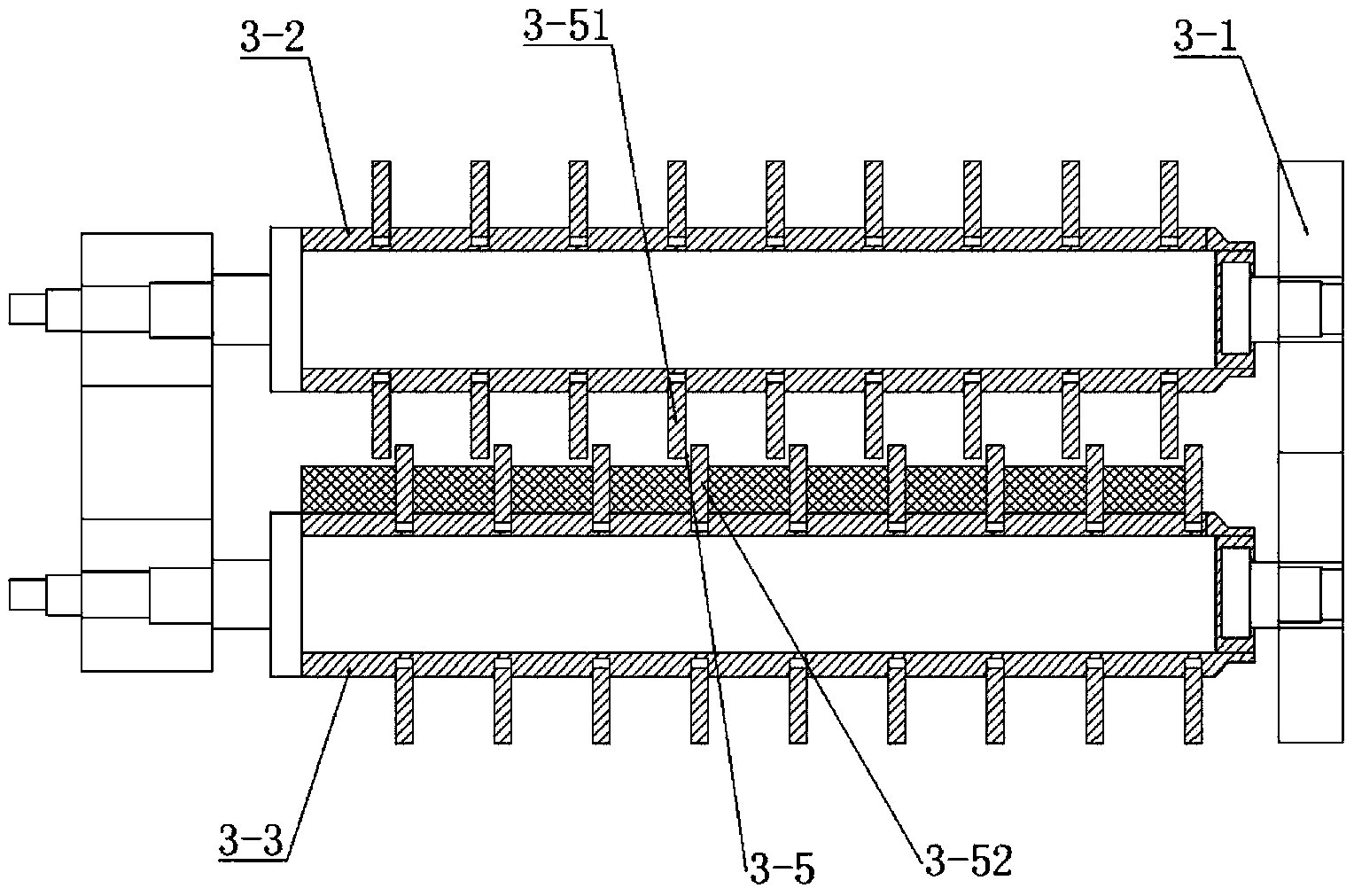

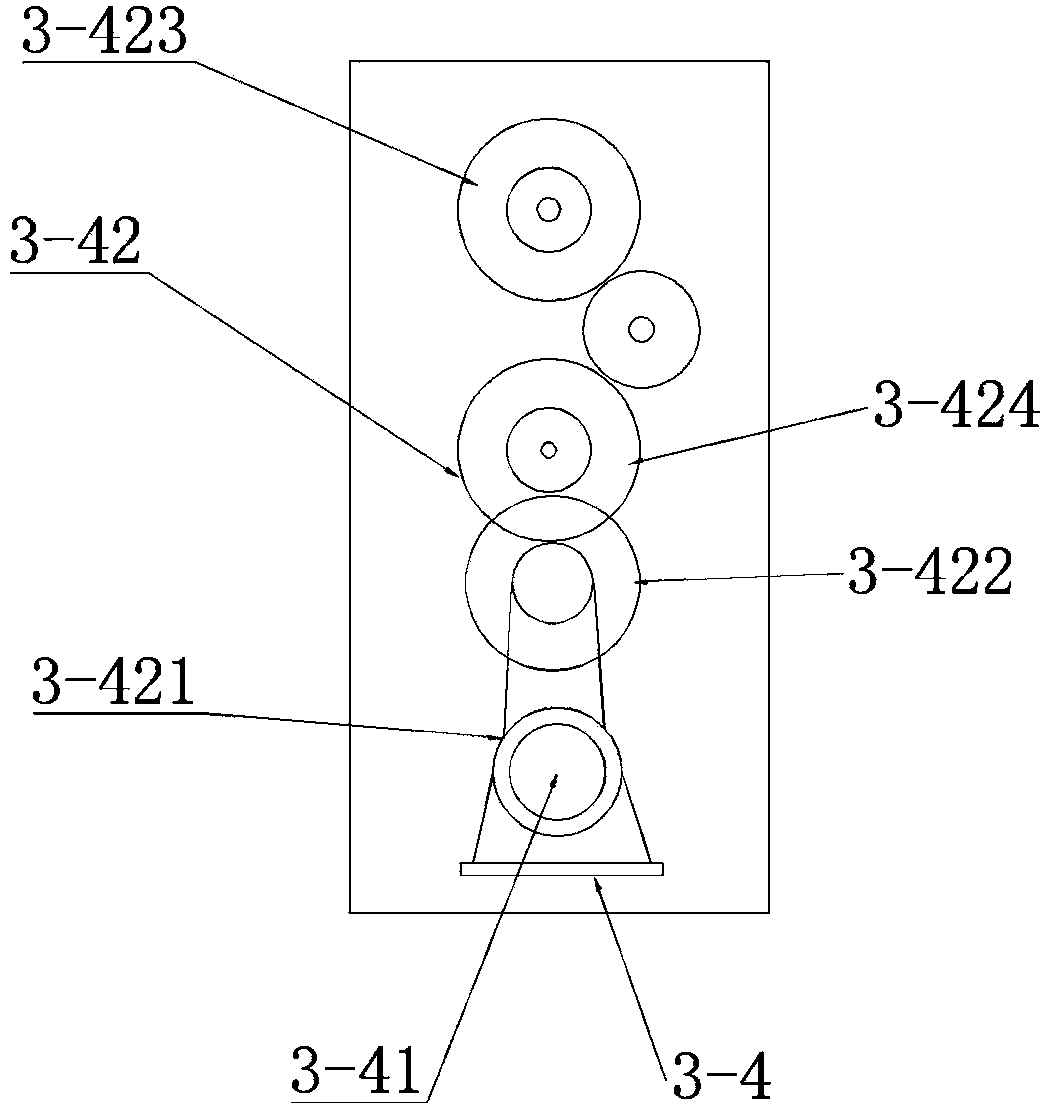

[0025] Such as Figure 1-Figure 8 As shown, a sheet slitting machine of the present invention comprises a frame 1 and a strip feeding mechanism 2, a slitting device 3, a strip winding mechanism 4, a strip loading mechanism 2, a strip The rewinding mechanism 4 is located at the front and rear of the slitting device 3, and the slitting device 3 includes a knife shaft support 3-1, upper and lower knife shafts 3-2, 3-3, and a knife shaft that drives the upper and lower knife shafts to rotate Several groups of shearing modules 3-5 arranged at certain intervals between the power unit 3-4 and the upper and lower cutter shafts, each group of shearing modules consists of an upper cutter 3-51 on the upper cutter shaft and a lower cutter shaft The upper and lower cutters 3-52 are formed, the upper cutter 3-51 and the lower cutter 3-52 are arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com