Optical fiber terminal fixing tool for winding optical fiber and optical fiber winding method

A technology of optical fiber terminal and fixing parts, which is applied in the field of optical fiber terminal fixing parts to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] Hereinafter, embodiments of the present invention will be described in detail.

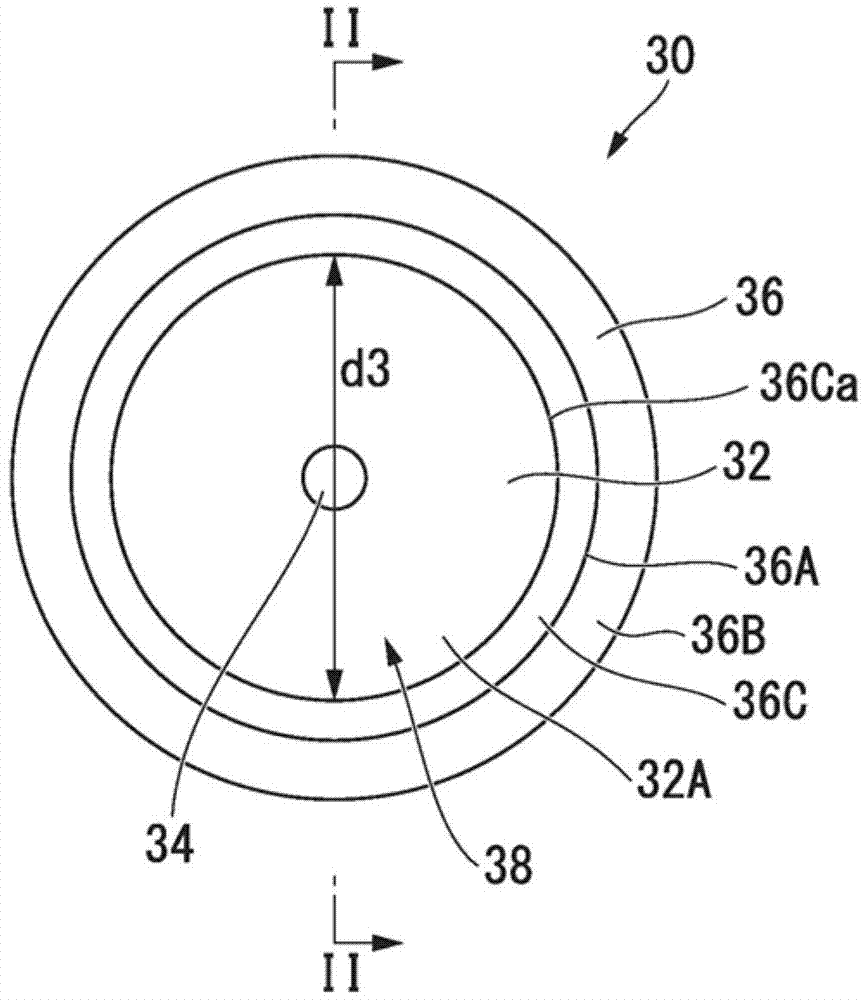

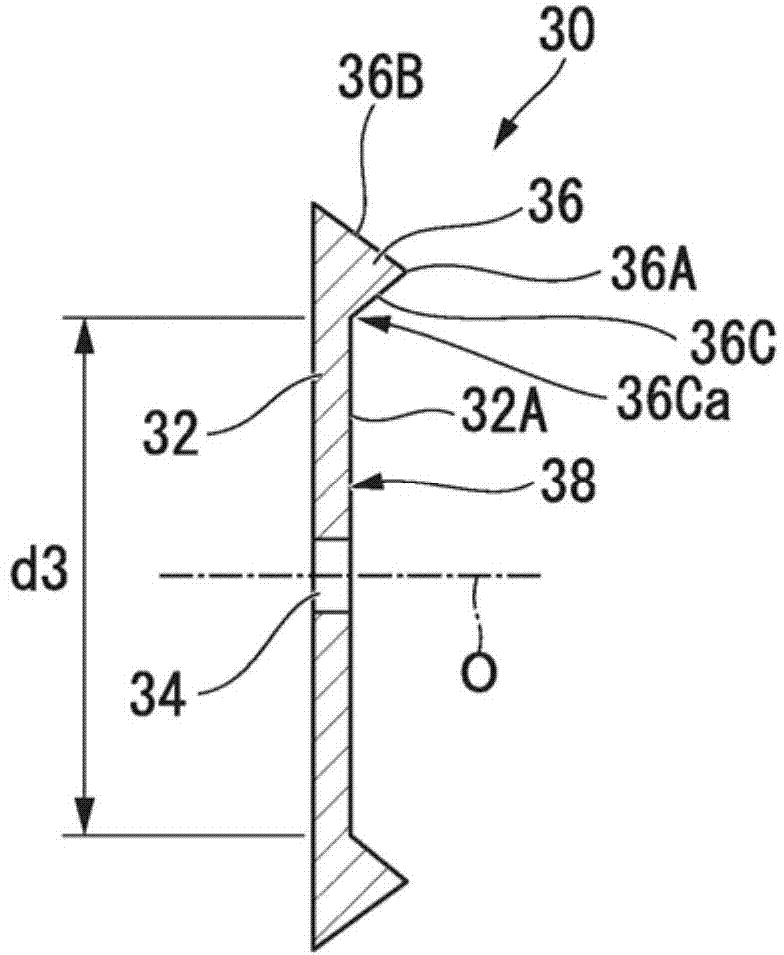

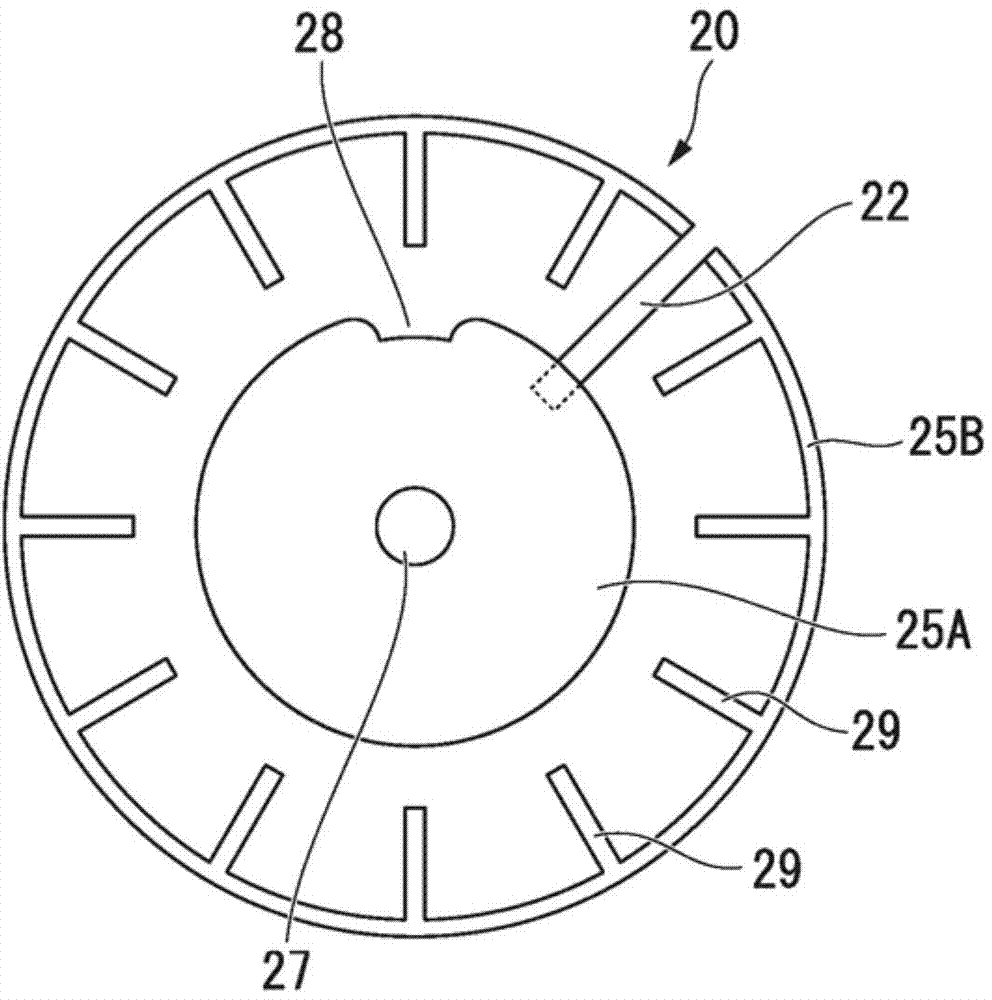

[0071] figure 1 , figure 2 The overall structure of the optical fiber terminal fixture according to the embodiment of the present invention is shown.

[0072] exist figure 1 , figure 2 Among them, the optical fiber terminal fixing member 30 is made of, for example, relatively hard resin such as ABS resin or metal such as aluminum, and is composed of a disc-shaped base (disk-shaped base) 32 as a whole. A shaft hole 34 through which a rotating shaft of a winding machine (not shown) is inserted is formed in a central portion of the disk-shaped base 32 so as to penetrate along the central axis O. As shown in FIG. In addition, an annular raised portion 36 protruding in a direction parallel to the central axis O is formed on a portion of one disk surface 32A of the disk-shaped base 32 near the outer peripheral edge.

[0073] The raised portion 36 is continuous along the circumferential d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com