Foamed ceramic plate kiln car

A technology of foamed ceramics and plate kiln cars, which is applied in the field of kiln cars, can solve the problems of material waste, achieve the effects of avoiding position movement, standardizing and uniform boundary shapes, and high boundary utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments, but this does not constitute any limitation to the present invention.

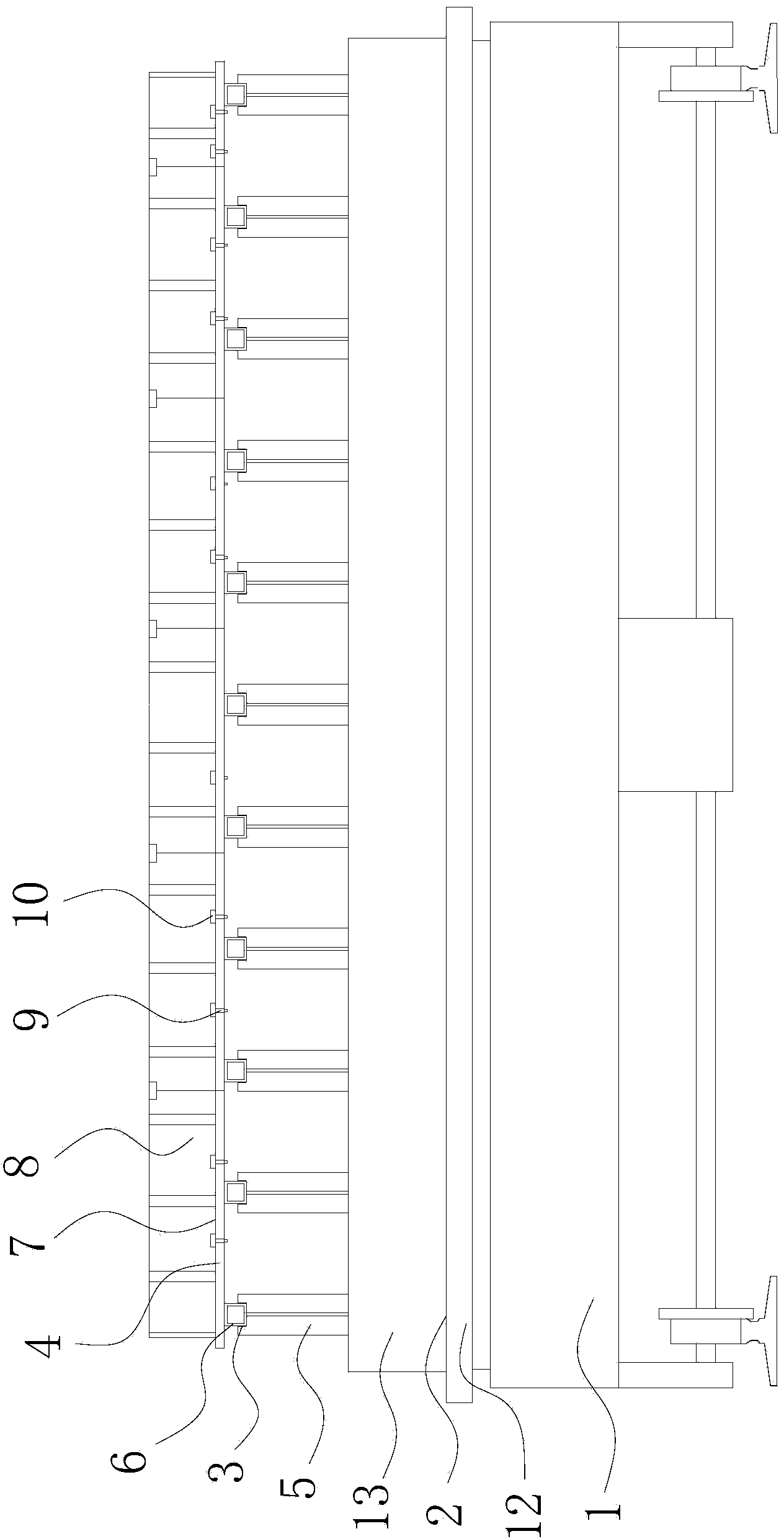

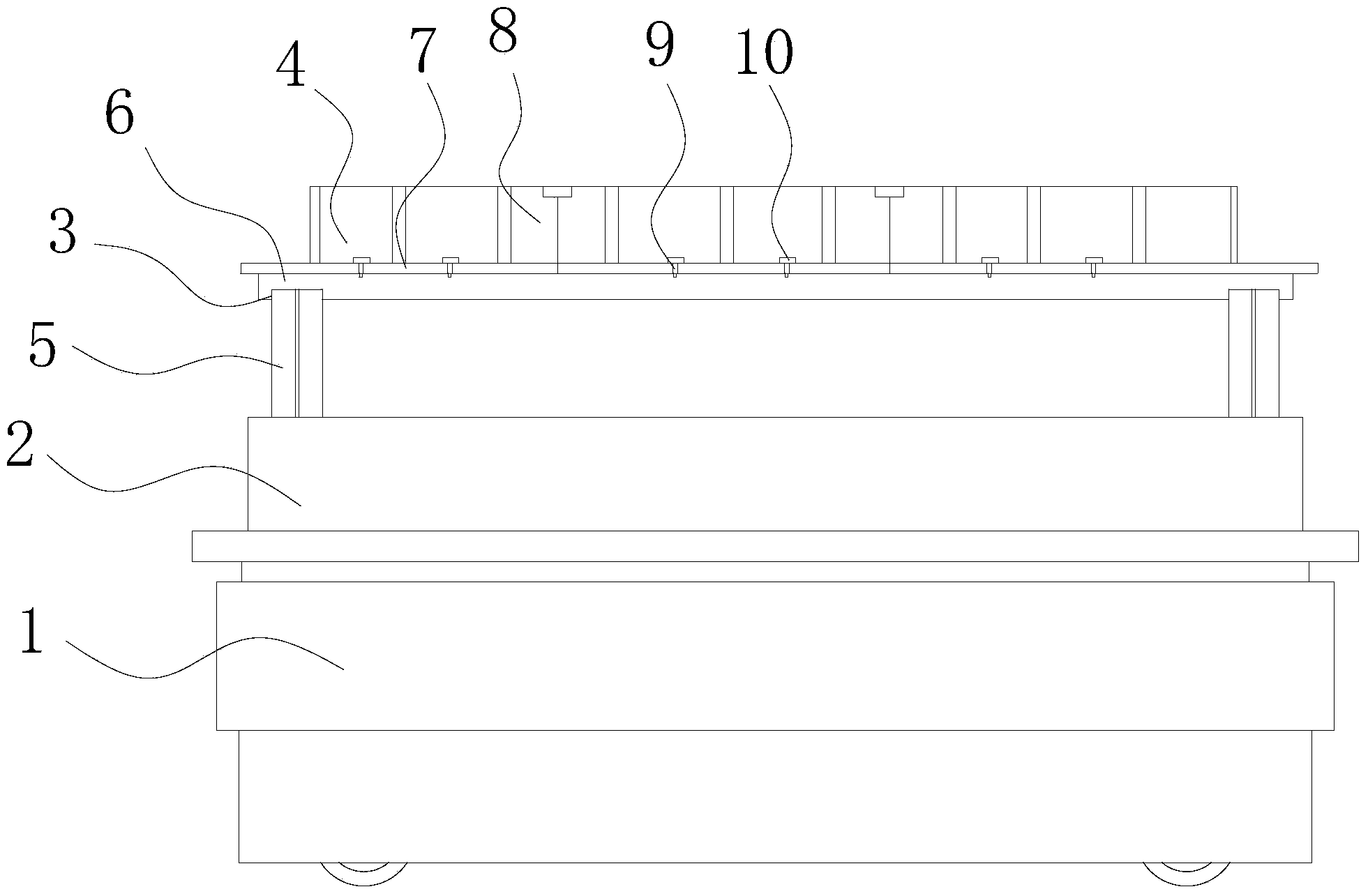

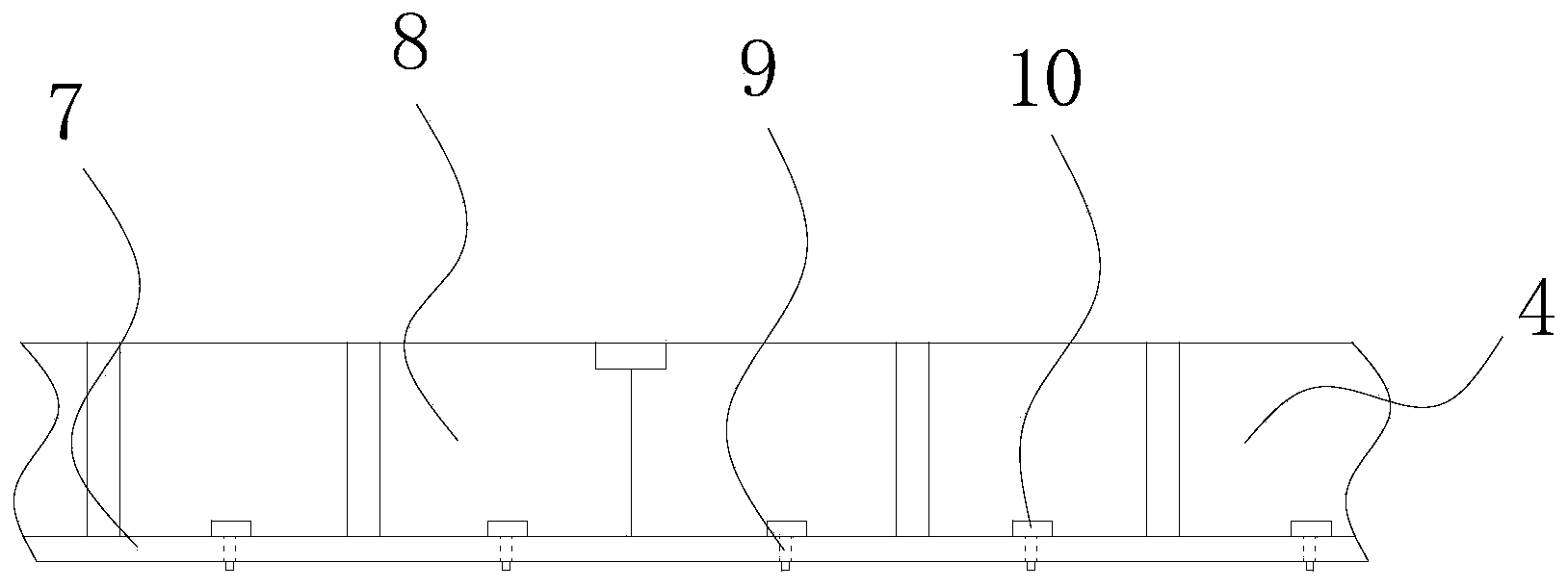

[0019] refer to Figure 1~3 As shown, a foamed ceramic plate kiln car of the present invention includes a car body 1, and the car body 1 is provided with a bottom layer 2, a column layer 3 and a plate layer 4 from bottom to top, and the column layer 3 is made of a plurality of refractory materials The column 5 is composed of a plurality of support beams 6. The lower end of the refractory column 5 is fixed above the bottom layer 2 and is symmetrical to the center line of the vehicle body 1. A support beam 6 is placed on the top of every two refractory column 5. The plate layer 4 is located directly above the support beam 6, the slab 4 includes a bottom plate 7 and a plurality of positioning baffles 8 arranged on the outer side above the bottom plate 7, and the plurality...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com