Method for testing material heat conductivity coefficient through transient plane heat source method

A plane heat source method and thermal conductivity technology, applied in the direction of material thermal development, etc., can solve the problems that cannot accurately reflect the properties of materials, cannot accurately reflect the research process, and the measurement results of thermal conductivity are incorrect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

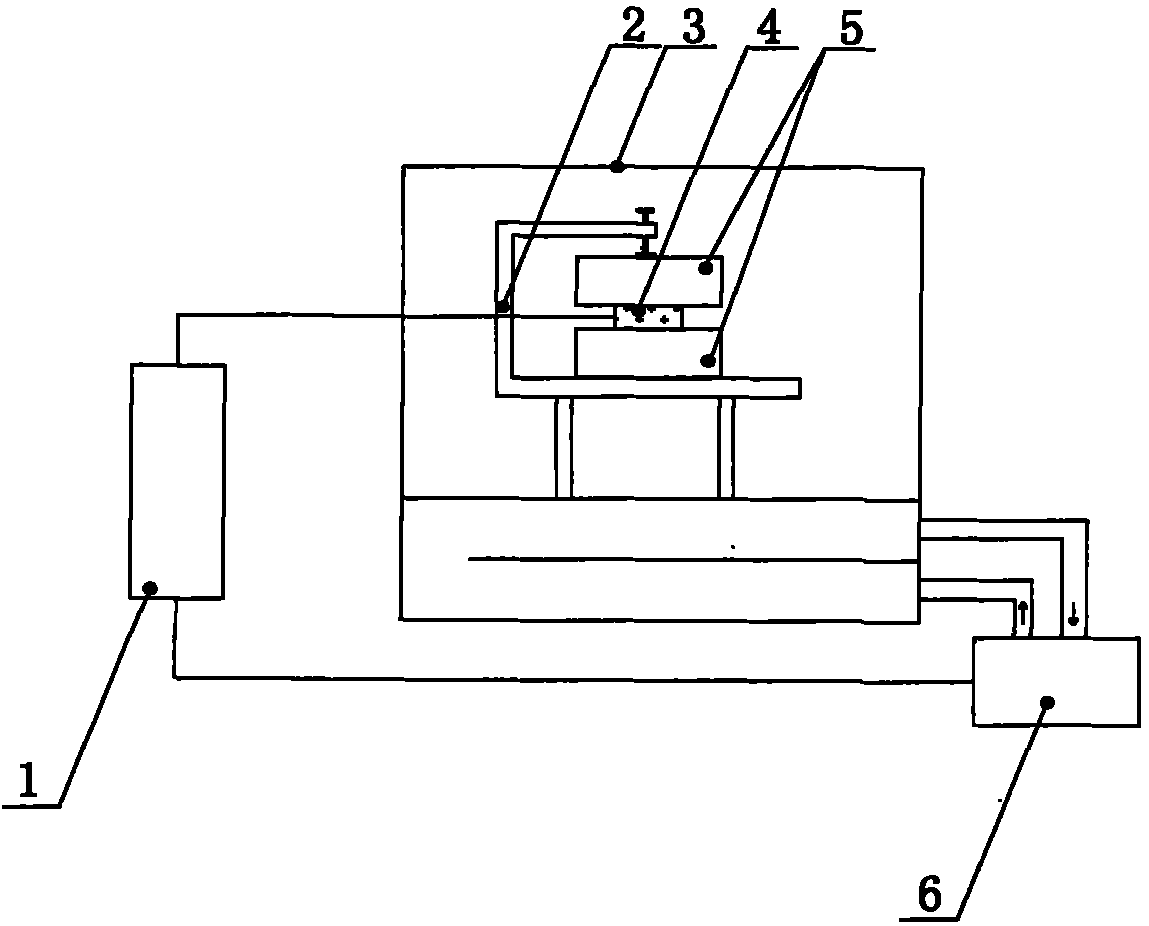

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail according to the examples below.

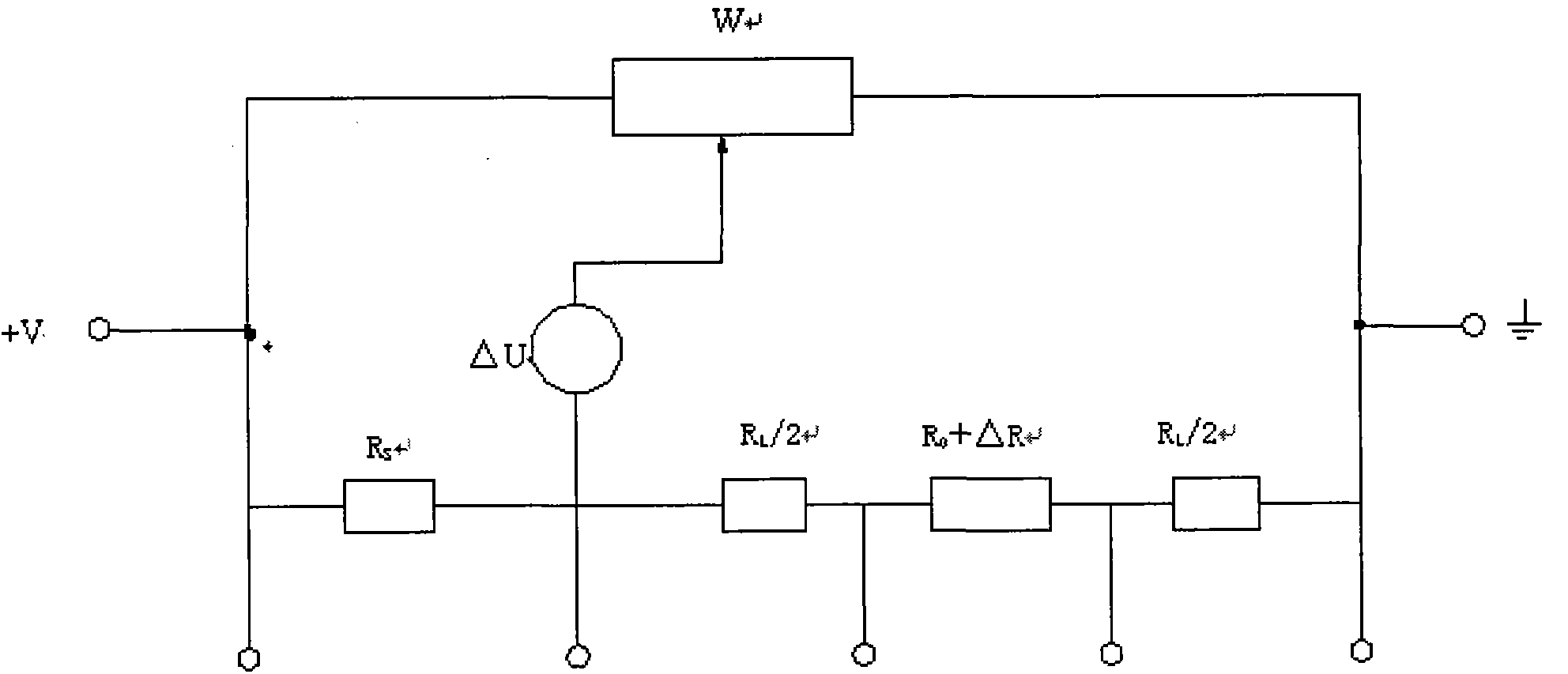

[0016] Balanced bridge: The voltage used for the balanced bridge should make the system current not greater than 1mA, and the reading of the digital voltmeter of the bridge test system is zero after the bridge is balanced.

[0017] Apply heat pulse: According to the total test time and output power, apply a constant direct current to the probe to generate a heat pulse in the sample, and divide the voltage at the initial moment of transient heating by testing the total resistance of the bridge system (that is, R s +R L +R o ), get the current I0 passing through the probe at this time, and the sliding contact of the potentiometer should not be adjusted during this test.

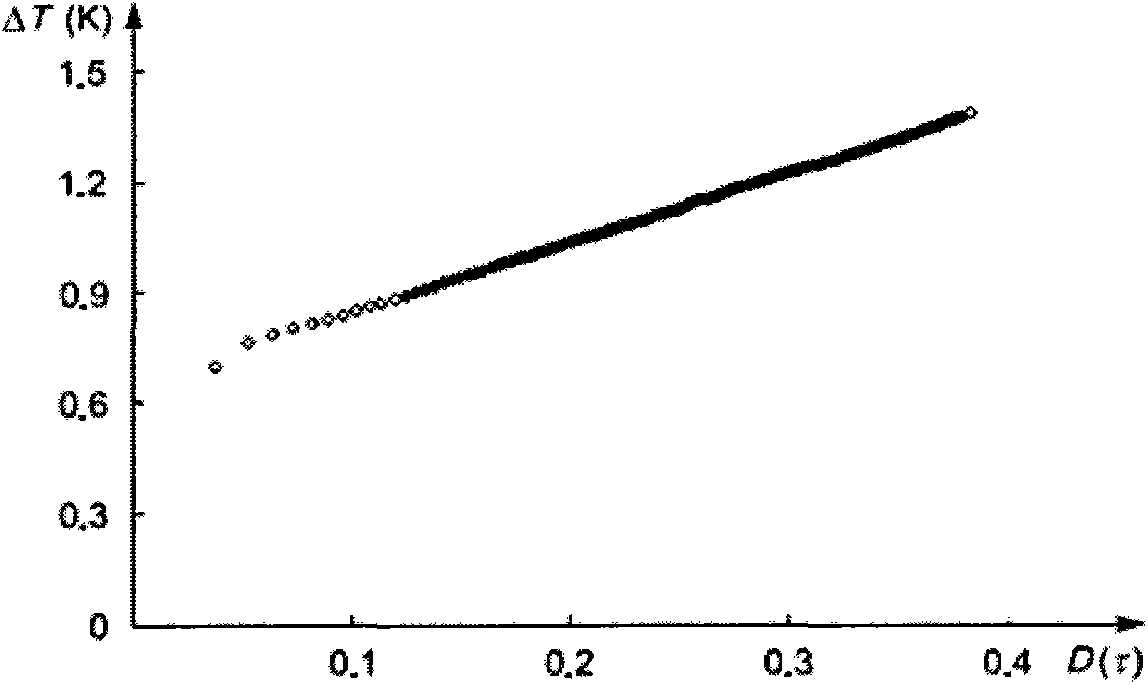

[0018] Acquisition of unbalanced voltage: within the total test time, scan and record the unbalanced voltage at an appropriate time interval, that is, the potential change △U, and the number of acquisitions sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com