An Optimal Calculation Method of Ultrasonic Scattering Coefficient for Crack Direction Identification

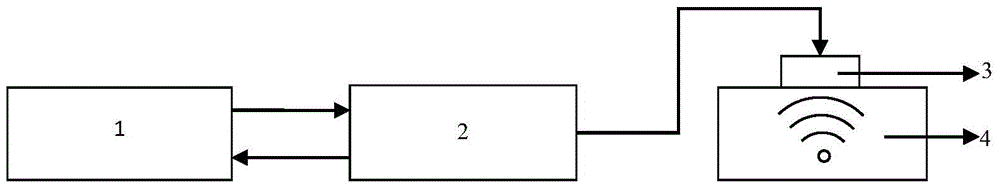

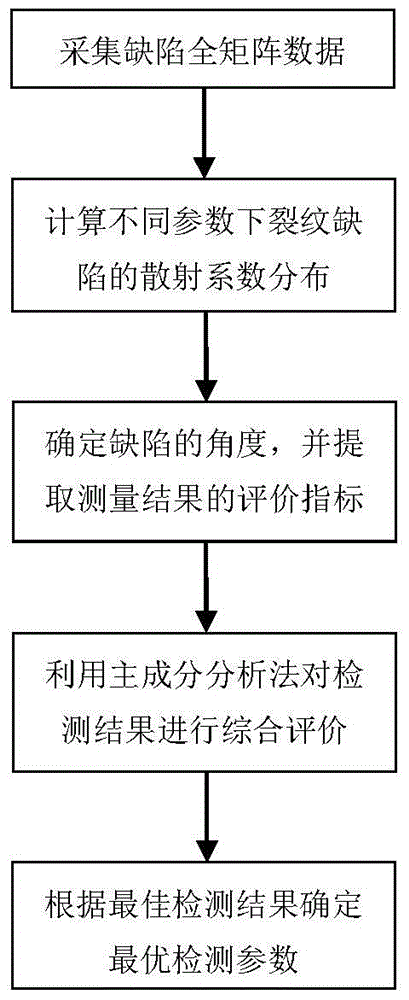

A technology of scattering coefficient and direction identification, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves and processing the response signal of detection, which can solve problems such as increasing the complexity of analysis problems and increasing the amount of calculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The validity of the method of the present invention will be described in detail below using the data obtained from CIVA simulation and detection experiments.

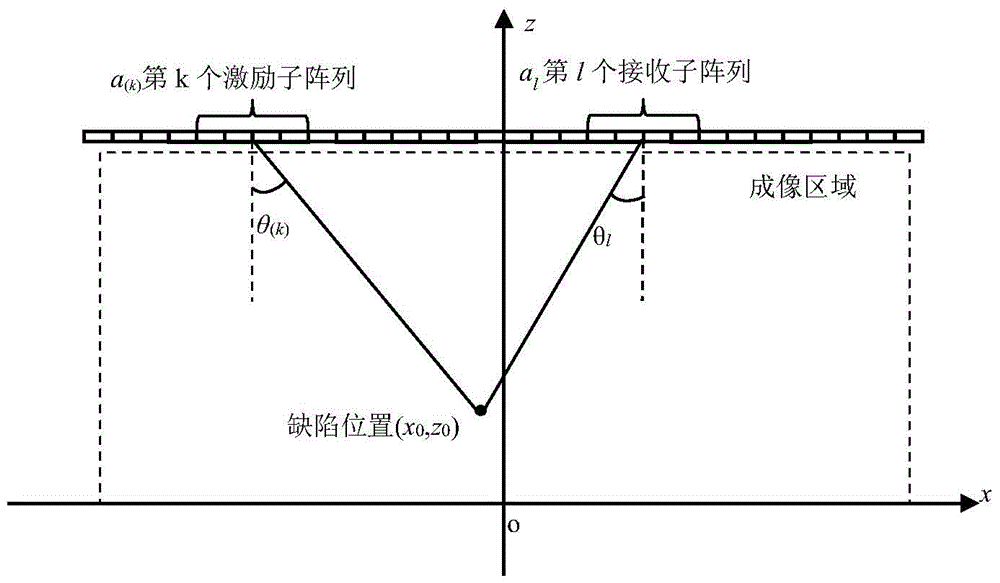

[0047] Using the ultrasonic simulation module in CIVA software, the ultrasonic phased array defect detection is simulated. In CIVA software, a simulation model containing crack defects at an angle of 15° to the horizontal direction is established, such as Figure 4 shown. Wherein, the base material is aluminum, and the crack length is 3 mm. The center frequency of the excitation signal is 5MHz, the sampling frequency is 100MHz, the phased array detection mode is the full matrix data acquisition mode, and the basic parameter settings of the probe are shown in Table 1.

[0048] Table 1 Basic parameters of the probe

[0049] Table1Basic parameters of the probe

[0050]

[0051] Step 1: Collect full matrix data of crack defects

[0052] Export the full matrix data of the detected crack defects from CIVA softw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com