Modeling method for dynamic machining features of complex curved surface

A curved surface processing and dynamic processing technology, applied in the field of CAD/CAM, can solve problems such as the inability to meet the adaptive processing of curved surfaces, and the dependence of programming on manual labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following is a detailed description of the technical solution of the present invention in conjunction with the accompanying drawings.

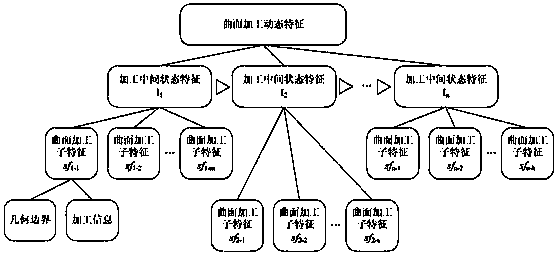

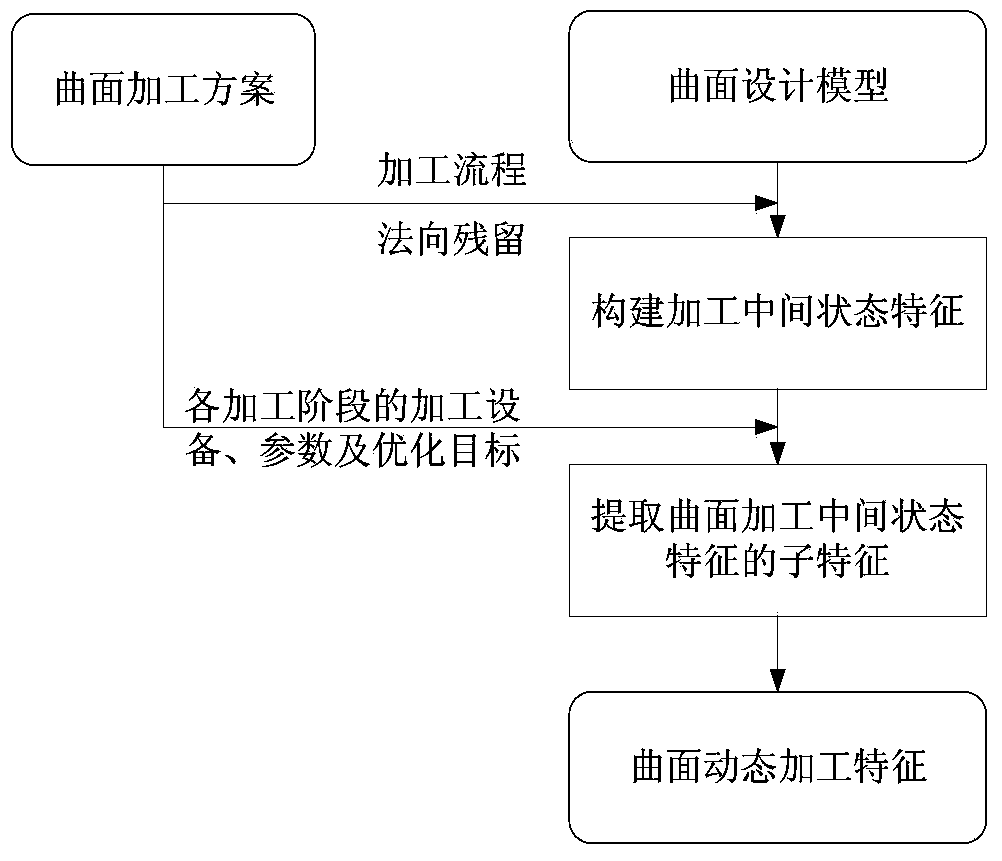

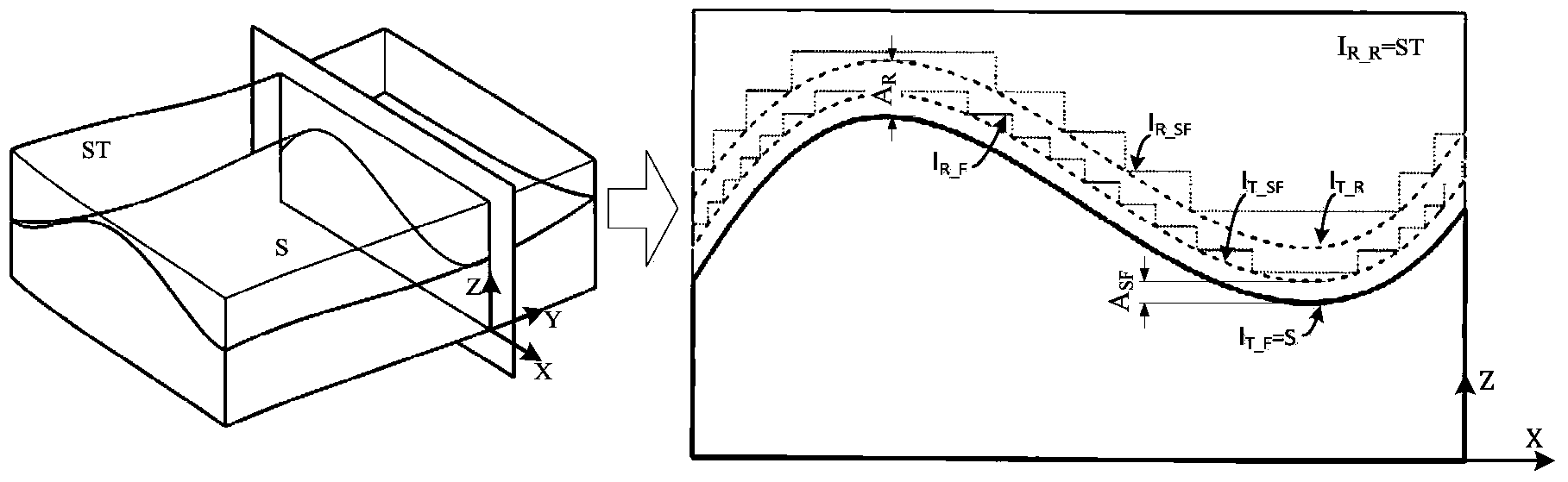

[0039] 1. Define the secondary data structure of the complex surface dynamic processing feature. Complex surface dynamic processing features include processing intermediate state feature level and surface processing sub-feature level, such as figure 2 shown. Each processing stage in the defined surface processing scheme corresponds to a processing intermediate state feature I i , for example, the surface machining plan contains three stages of roughing, semi-finishing and finishing, then the surface contains three processing intermediate state features of roughing, semi-finishing and finishing features, so

[0040] S = ∪ i n I i

[0041] I i The geometric information contained in is the geometric s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com