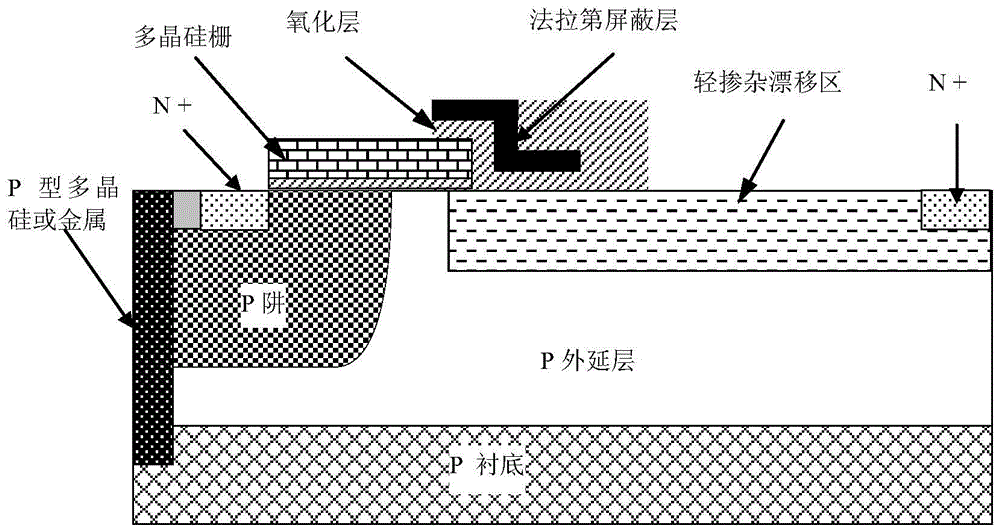

Radio frequency lateral double diffused field effect transistor and its manufacturing method

A field-effect transistor and lateral double-diffusion technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of reducing the electric field intensity under the polysilicon gate and affecting the life of the device, so as to reduce the output The effect of capacitance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for manufacturing a radio-frequency lateral double-diffused field-effect transistor, comprising the following steps:

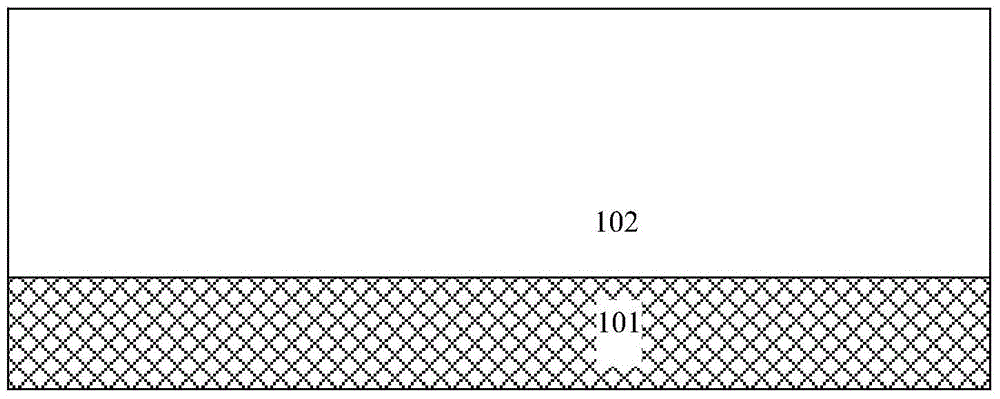

[0042] 1. grow lightly doped P-type epitaxial layer 102 on heavily doped P-type substrate 101, as figure 2 shown;

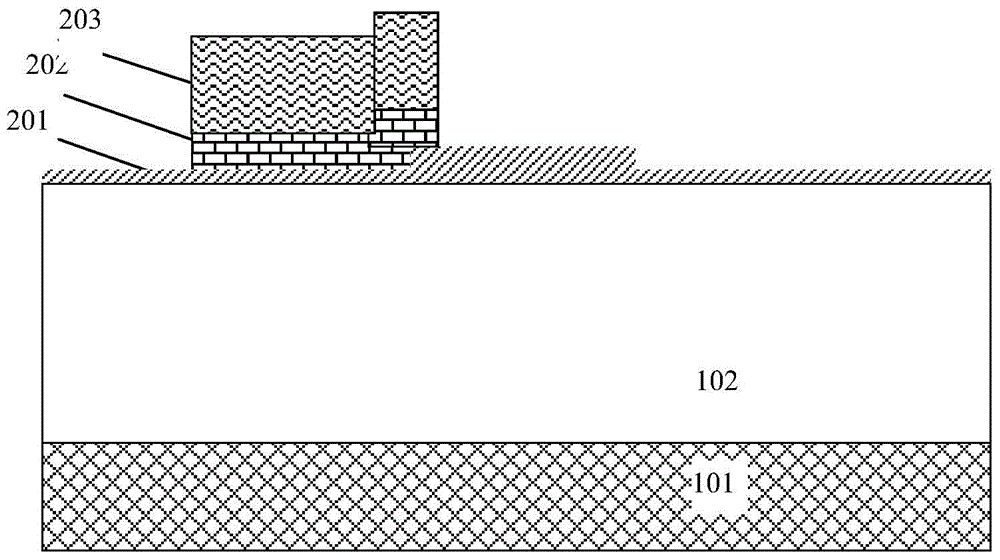

[0043] 2. growing a first oxide layer by thermal oxidation on the P-type epitaxial layer 102;

[0044]3. Keep the first oxide layer in the middle of the P-type epitaxial layer 102, and etch away all other first oxide layers on the P-type epitaxial layer;

[0045] 4. On the P-type epitaxial layer 102, the second oxide layer is grown by thermal oxygen. The second oxide layer is thinner than the first oxide layer. From the left end to the right end, the structure of the oxide layer on the P-type epitaxial layer 102 is thick and thin. structure;

[0046] 5. Deposit polysilicon on the oxide layer 201, etch the polysilicon gate 202 by photolithography, the left part of the polysilicon gate covers the right end of the thin oxide laye...

Embodiment 2

[0063] RF lateral double-diffused field-effect transistors, such as Image 6 As shown, a P-type epitaxial layer 102 is grown on a P-type substrate 101, a P-type epitaxial layer 102 is formed with a P-well 401 on the left, and an N-type drift region 301 is formed on the right. On the P-type epitaxial layer 102 between the left parts of the region 301, a stepped gate oxide and a stepped polysilicon gate 202 are sequentially formed on the left and right, and above the N-type drift region 301 adjacent to the right side of the polysilicon gate 202. A stepped Faraday shielding dielectric layer with a high left and a low right and a Faraday shielding metal 601. The stepped Faraday shielding dielectric layer is located between the stepped Faraday shielding metal layer 601 and the N-type drift region 301, and is high from left to right. There are three thickness distributions of , medium and low, the doping concentration of the N-type drift region located directly below the stepped Far...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com