Heat exchanger and air conditioner

A technology for heat exchangers and heat transfer tubes, applied to indirect heat exchangers, heat exchanger types, heat sinks, etc., can solve problems such as reduced frost resistance, increased air ventilation resistance, and air flow obstruction, achieving Improved rigidity, improved frost resistance, and improved heat exchange performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

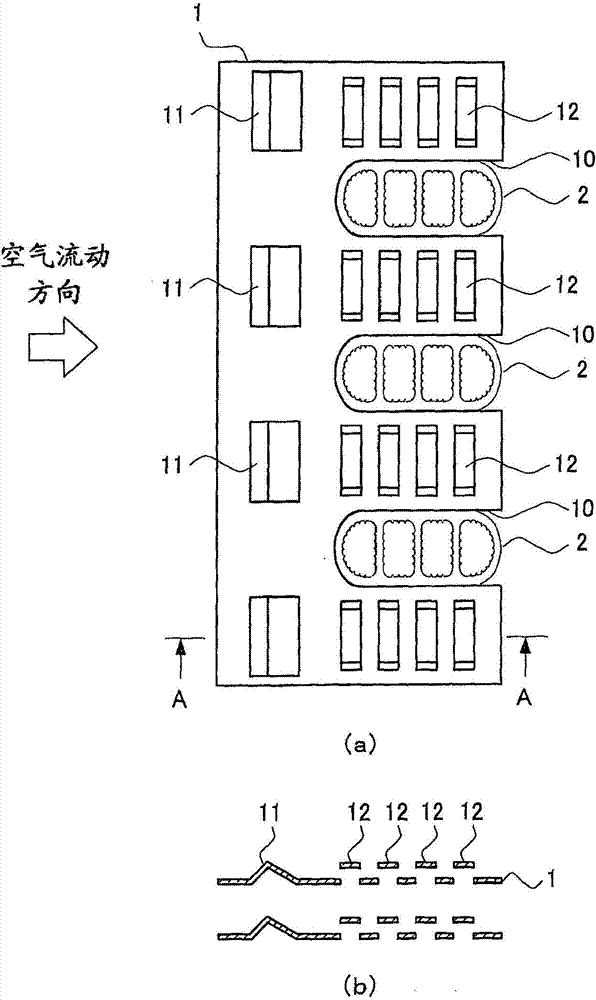

[0029] figure 1 It is a block diagram of the heat exchanger in Embodiment 1 of this invention. figure 1 (a) is a figure which shows the arrangement|positioning relationship of a plate-shaped fin and a heat transfer tube, figure 1 (b) means that figure 1 (a) A-A section diagram. In addition, in figure 1 In , the key parts of the heat exchanger are schematically represented.

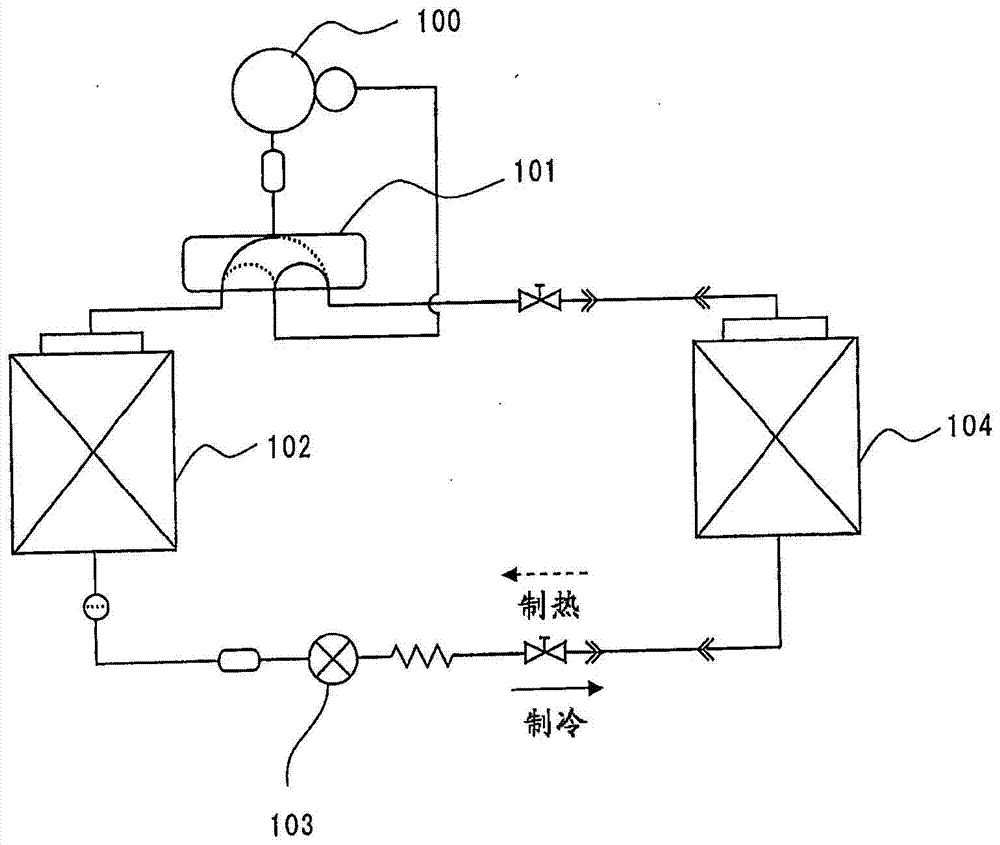

[0030] Such as figure 1 As shown, the fin-tube heat exchanger according to Embodiment 1 has plate-shaped fins 1 and flat tubes 2 as heat transfer tubes. This heat exchanger is mounted on, for example, an air conditioner, and exchanges heat between a fluid (hereinafter also referred to as air flow) such as air passing through the heat exchanger and a refrigerant (medium) flowing through the flat tubes 2 .

[0031] The flat tube 2 is a heat transfer tube whose cross-sectional shape is flat or wedge-shaped. The long axis of the flat tube 2 is oriented toward the flow direction of the fluid (left-right ...

Embodiment approach 2

[0069] Figure 7 It is a configuration diagram of a heat exchanger according to Embodiment 2 of the present invention. Figure 7 (a) represents the configuration relationship between plate fins and heat transfer tubes, Figure 7 (b) means Figure 7 (a) A-A section. In addition, in Figure 7 In , the key parts of the heat exchanger are schematically represented.

[0070] like Figure 7 As shown, in Embodiment 2, notches 10 for inserting the plurality of flat tubes 2 are formed at the upstream end of the plate fin 1 . In addition, the airflow downstream side of the cutout 10 portion of the plate-shaped fin 1 is a flat flat portion.

[0071] In Embodiment 2, the waffle-shaped portion 11 and the slit-shaped portion 12 are also formed on the plate-shaped fin 1 .

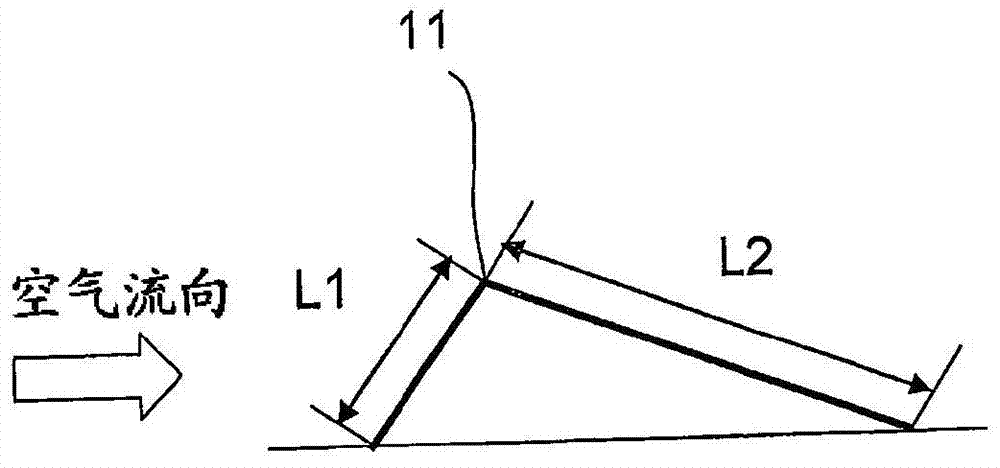

[0072] The waffle-shaped portion 11 is provided on the upstream side of the air flow from the slit-shaped portion 12 . In addition, the waffle-shaped portion 11 is disposed on the upstream side of the upstream end...

Embodiment approach 3

[0084] Figure 9 It is a configuration diagram of a heat exchanger according to Embodiment 3 of the present invention. Figure 9(a) represents the configuration relationship between plate fins and heat transfer tubes, Figure 9 (b) means Figure 9 (a) A-A section. In addition, in Figure 9 In , the key parts of the heat exchanger are schematically represented.

[0085] Such as Figure 9 As shown, in Embodiment 3, a plurality of slit-shaped portions 12 are formed on the plate fin 1 , and the opening width of the slit-shaped portion 12 on the downstream side is formed wider than that of the opening of the slit-shaped portion 12 on the upstream side. Wide. That is, the opening width W of the slit is formed to be larger as it goes from the upstream side to the downstream side.

[0086] The other configurations are the same as those in Embodiment 1 or 2 above, and the same reference numerals are assigned to the same parts. In addition, in Figure 9 In the example shown, al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com