Hand sanitizer and preparation method thereof

A hand sanitizer, technology in parts by weight, applied in the field of hand sanitizer, can solve problems such as poor effect and inability to resist Clostridia, achieve smooth skin, highlight bactericidal effect, and keep skin moist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

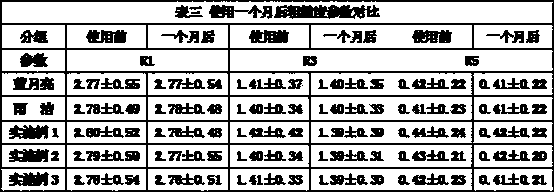

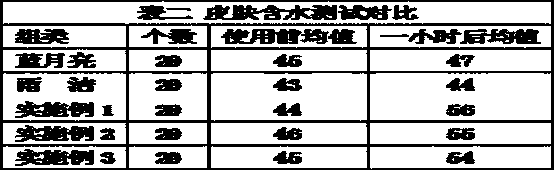

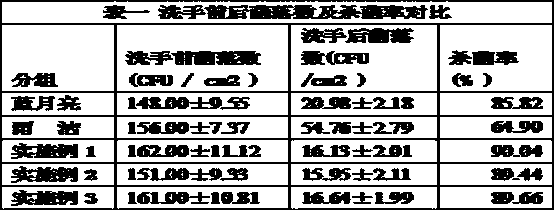

[0041] Embodiment 1: A, get 12 grams of Ruo Ye, 11 grams of Galangal, join in 120 grams of deionized water, decoct for 80 minutes, pass through 200 orders of nylon gauze, get its filtrate; B, under 70 ℃ of conditions, Add 9 grams of sodium lauryl polyoxyethylene ether sulfate, 8 grams of sodium lauroyl sarcosinate, 3 grams of nonylphenol polyoxyethylene ether, and 3 grams of isopropyl myristate to the filtrate in step A successively, and stir for 30 Minutes; C, 7 grams of chitosan, 6 grams of sodium alginate, 4 grams of clove oil, 3 grams of litsea cubeba oil, and 5 grams of jojoba oil were added to the three-dimensional mixer, and stirred at 50 ° C for 50 Minutes; D. Add the mixture in step B and step C to the mixer, stir for 20 minutes, then add 1 g of sodium chloride, and stir for 60 to 80 minutes.

Embodiment 2

[0042] Embodiment 2: A, get 11 grams of Ruoye leaves and 9 grams of galangal, join in 110 grams of deionized water, decoct for 80 minutes, pass through 200 orders of nylon gauze, get its filtrate; B, under 70 ℃ of conditions, Add 9 grams of sodium lauryl polyoxyethylene ether sulfate, 7 grams of sodium lauroyl sarcosinate, 3 grams of nonylphenol polyoxyethylene ether, and 2 grams of isopropyl myristate to the filtrate in step A successively, and stir for 30 Minutes; C, 6 grams of chitosan, 5 grams of sodium alginate, 3 grams of clove oil, 2 grams of litsea cubeba oil, and 4 grams of jojoba oil were added to the three-dimensional mixer, and stirred at 50 ° C for 50 Minutes; D. Add the mixture in step B and step C to the mixer, stir for 20 minutes, then add 0.8 g of sodium chloride, and stir for 60 to 80 minutes.

Embodiment 3

[0043] Embodiment 3: A, get 13 grams of Ruo Ye, 11 grams of Galangal, join in 130 grams of deionized water, decoct for 80 minutes, pass through 200 orders of nylon gauze, get its filtrate; B, under 70 ℃ of conditions, Add 11 grams of sodium lauryl polyoxyethylene ether sulfate, 9 grams of sodium lauroyl sarcosinate, 4 grams of nonylphenol polyoxyethylene ether, and 3 grams of isopropyl myristate to the filtrate in step A successively, and stir for 30 Minutes; C, 8 grams of chitosan, 7 grams of sodium alginate, 5 grams of clove oil, 4 grams of litsea cubeba oil, and 6 grams of jojoba oil were added to the three-dimensional mixer, and stirred at 50 ° C for 50 Minutes; D. Add the mixture in step B and step C to a blender, stir for 20 minutes, then add 1.5 grams of sodium chloride, and stir for 60 to 80 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com