A material screening and mixing equipment

A material sieve and equipment technology, applied in sieves, mixers, chemical/physical processes, etc., can solve the problems of quality decline, long mixing time, poor effect, etc., to improve quality and quality, high uniformity, and ensure continuous The effect of running

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

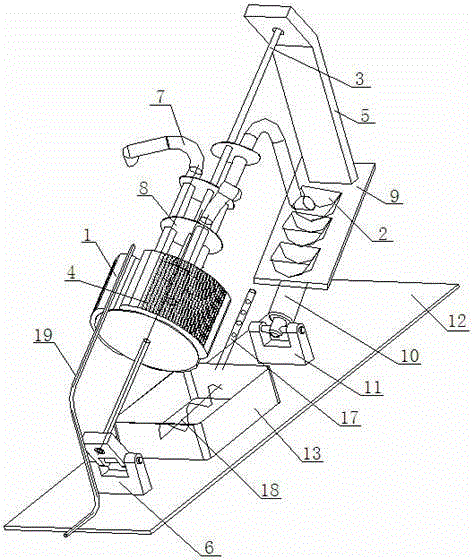

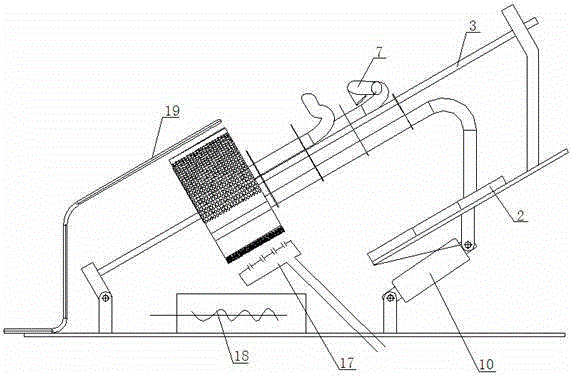

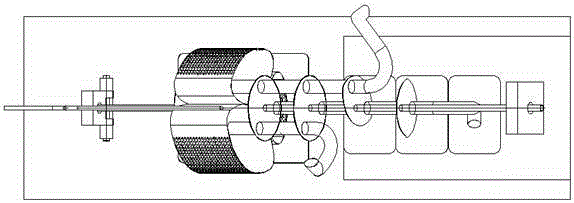

[0027] see Figure 1-4 , a material screening and mixing equipment, including two or more feeding devices, two or more raw material bins 2, two or more sieve buckets 4, a material receiving device and a rotating shaft 3. The feed device, the raw material bin 2 and the sieve bucket 4 correspond one by one, and the two or more sieve buckets 4 are respectively fixed on the rotating shaft 3, and the two or more sieve buckets 4 The material barrel 1 is formed by connecting them through edges; the material barrel 1 can be cylindrical or conical, and the material barrel 1 ensures the balance and stability of material screening. According to the type of pre-mixture, the number of feeding devices, raw material bins 2 and sieve buckets 4 is designed; the number of sieve buckets 4 is given according to the amount of each pre-mixture. 3. Screen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com