Safe economical square billet caster tundish casting control device

A bracket and fixing bolt technology, which is applied in the field of safe and economical billet casting machine tundish casting control device, can solve the problems of unsafe personnel close to high temperature, high labor intensity, waste of molten steel, etc., and improve the working space and working conditions , solve the effect of high labor intensity and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

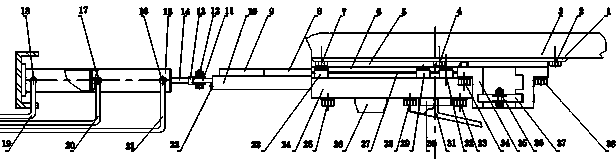

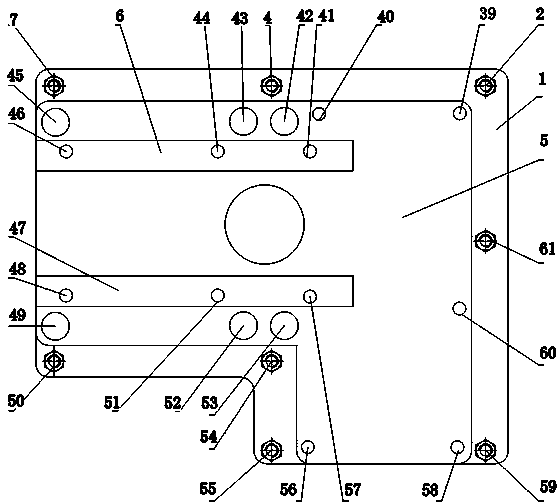

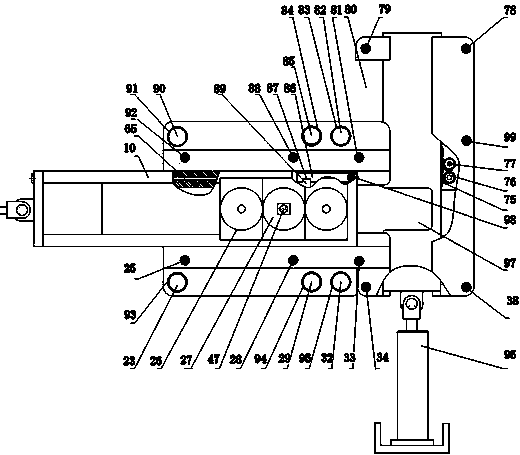

[0032] Such as figure 1 , 2 , 3, 4, 5, 6, and 7, it includes a fixed bottom plate (1), which is fixed by bottom plate fixing bolts I (2), bottom plate fixing bolts II (4), and bottom plate fixing bolts III (7). ), bottom plate fixing bolt Ⅳ (50), bottom plate fixing bolt Ⅴ (54), bottom plate fixing bolt Ⅵ (55), bottom plate fixing bolt Ⅶ (59), bottom plate fixing bolt Ⅷ (61) are fixed to the tundish shell (3) Upper; the middle left part of the fixed bottom plate (1) has a convex arc surface (6) on one side and a convex arc surface (47) on the other side, and a bracket is provided on the convex arc surface (6) on one side to fix the inner Wire Ⅰ (46), bracket fixing inner wire II (44), bracket fixing inner wire III (41), and bracket fixing inner wire IV (48) on the convex curved surface (47) on the other side Frame fixing inner wire Ⅴ (51), bracket fixing inner wire Ⅵ (57); the middle and left part of the fixed bottom plate plane (5) of the fixed bottom plate (1) is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com