Processing method of step surface of rubber workpiece

A processing technology and step surface technology, applied in the field of processing technology of rubber workpiece step surface, can solve the problems of long cycle and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

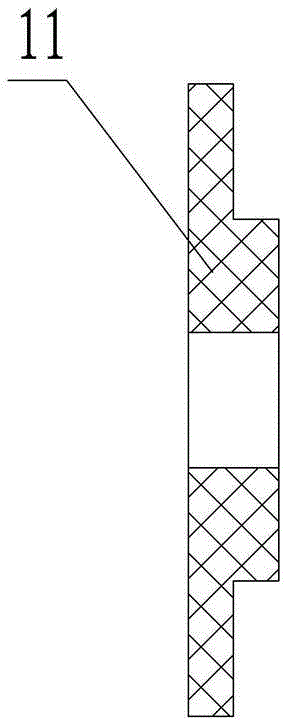

[0019] The embodiment of the processing technology method of rubber workpiece step surface of the present invention: the method processing figure 1 For the rubber gasket shown, the specific steps are as follows:

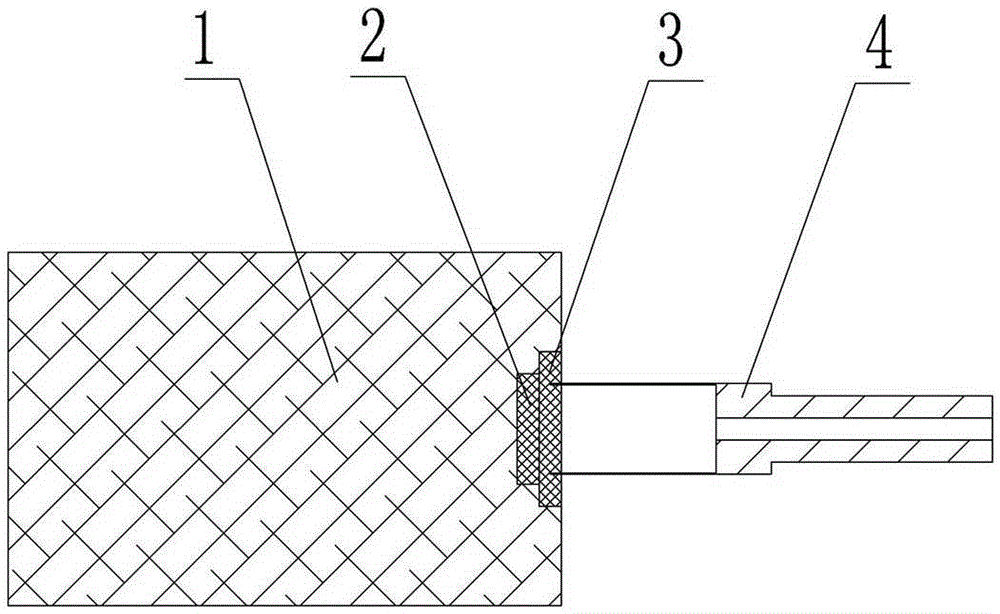

[0020] ① Utilize the first hollow drill bit to drill a hole on a rubber plate, and produce a circular plate-shaped blank 3 after processing, wherein the thickness of the rubber plate is equal to the thickness of the rubber washer, and the inner diameter of the first hollow drill bit is equal to that of the large diameter section of the rubber washer outer diameter;

[0021] ② Utilize the second hollow drill bit to process the center hole on one end surface of the blank 3, the inner diameter of the second hollow drill bit is equal to the aperture of the center hole;

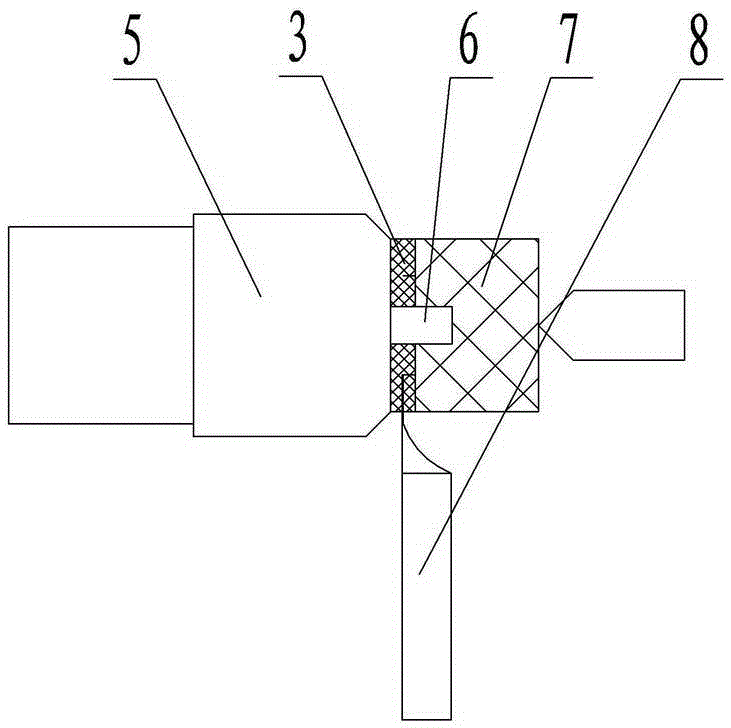

[0022] ③ if figure 2 As shown, the blank 3 is put into the positioning hole of the positioning tool 1, the positioning tool is a wooden positioning block, the positioning hole is arranged on an end su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com