Infrared-heating graphite purification furnace with stirrer

A graphite purification furnace and infrared heating technology, applied in the field of graphite processing equipment, can solve the problems of reduced graphite purification effect, influence of graphite purification quality, inaccurate temperature control, etc., and achieve the effect of good heating effect, good purification effect and uniform heating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

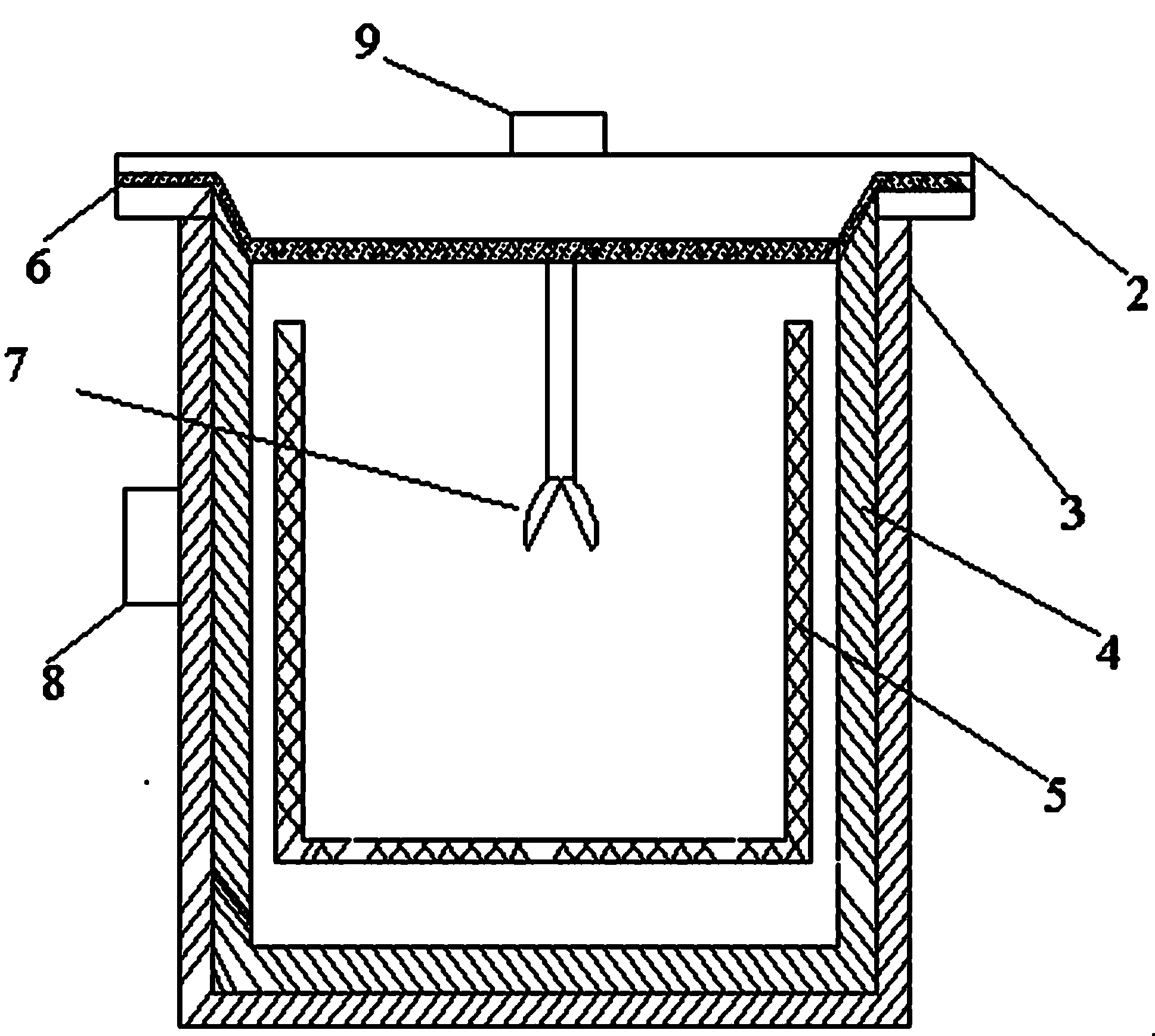

[0010] Such as figure 1 Shown, a kind of infrared heating graphite purification furnace with stirrer comprises shell 3, top cover 2, and the underside of top cover 2 is provided with insulation cover 6; The inside of shell 3 is provided with thermostat, and thermostat is set by The temperature regulator 8 outside the casing 3 is controlled, and the temperature regulator 8 adopts PID control; the inside of the casing 3 is provided with an insulation layer 4; the insulation cover 6 cooperates with the opening of the insulation layer 4 to form the infrared heating purification furnace with agitator The inner side of the thermal insulation layer 4 is provided with an infrared heater 5, the infrared heater 5 is barrel-shaped, and the lower end of the thermal insulation cover 6 is fixed with an agitator 7, so that the heating is more uniform and the reaction ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap