A kind of equipment and method for preparing carboxymethylated rice bran polysaccharide

A rice bran polysaccharide and carboxymethylation technology, which is applied in the field of preparation of carboxymethylated rice bran polysaccharide and rice bran polysaccharide carboxymethylation reaction, can solve the problems of affecting the reaction effect and uneven energy absorption, so as to improve the antioxidant activity, High free radical scavenging capacity, enhanced antioxidant activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

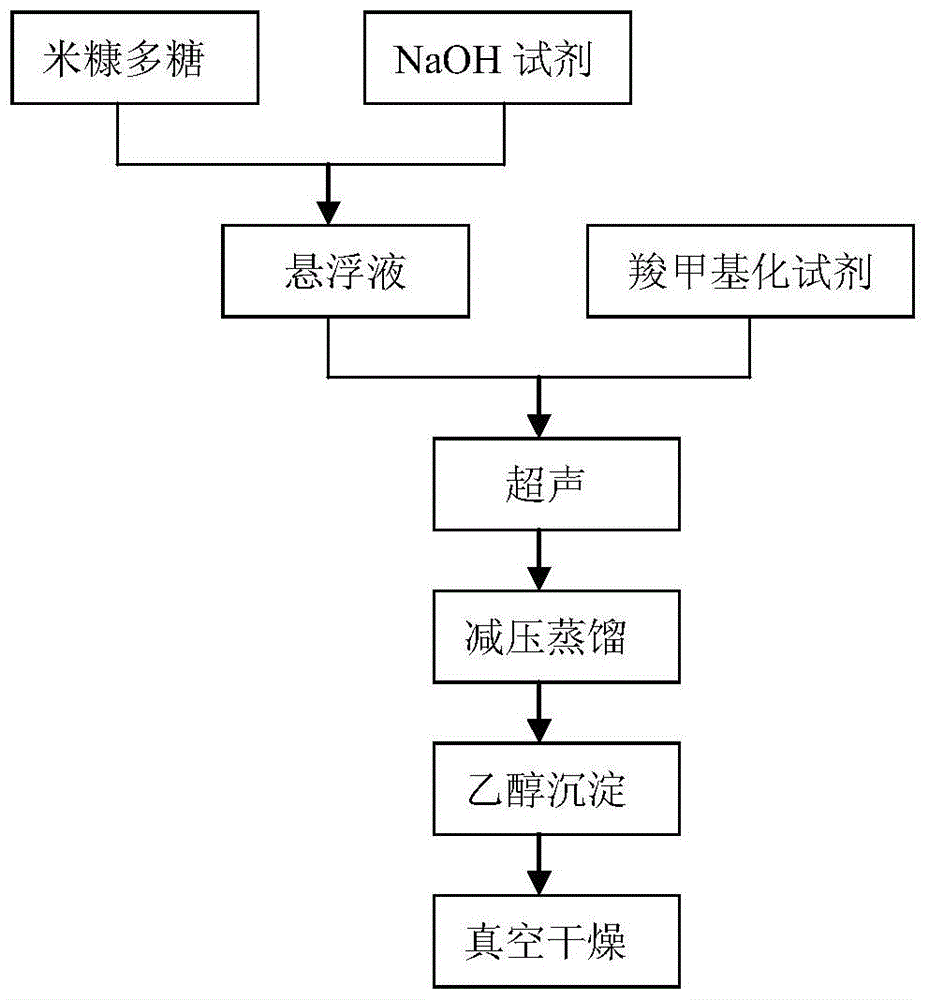

Method used

Image

Examples

Embodiment 1

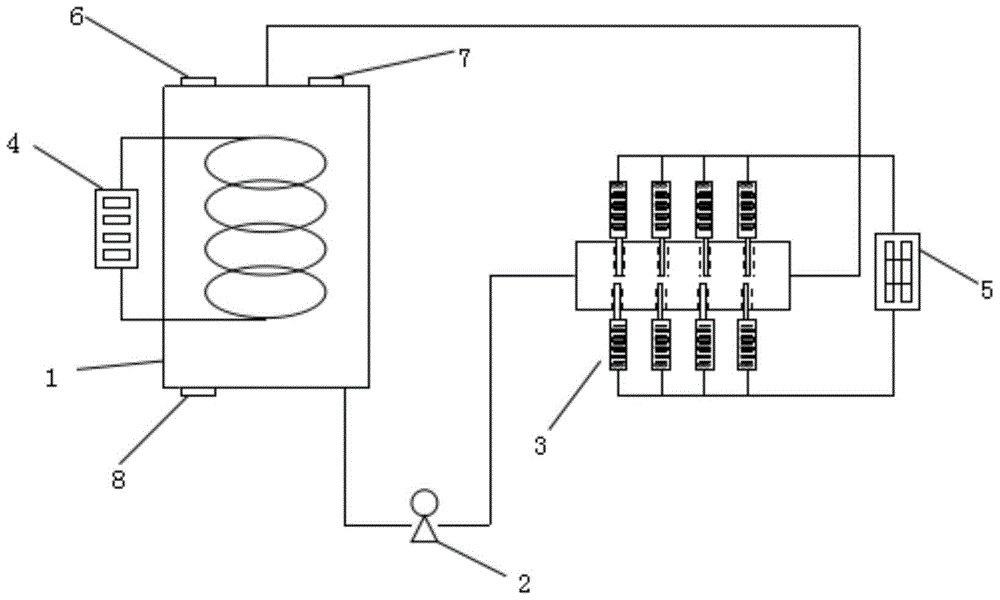

[0030] refer to figure 1 , a kind of equipment for preparing carboxymethylated rice bran polysaccharide, comprising a reactor 1, a circulation pump 2, an ultrasonic generator 3, a temperature control device 4, an ultrasonic controller 5, a liquid feed port 6, a fixed feed port 7, and an outlet The feed port 8 is composed of; the top of the reactor 1 is provided with a liquid feed port 6 and a solid feed port 7, and the bottom end is provided with a discharge port 8, the temperature control device 4 is connected with the reactor 1, and the circulation pump 2 The inlet of the pump is connected to the bottom of the reactor 1, the outlet of the circulating pump 2 is connected to the ultrasonic generator 3, the outlet of the ultrasonic generator 3 is connected to the top of the reactor 1, and the ultrasonic controller 5 is connected to the ultrasonic generator 3.

[0031] The equipment is an external circulation type ultrasonic reaction device, the probes of the ultrasonic generato...

Embodiment 2

[0042] The difference with Example 1 is:

[0043] The ultrasonic treatment conditions in step d are: ultrasonic power 140W, ultrasonic time 10min, reaction temperature 40°C;

[0044] In step f, three times the volume of absolute ethanol was added to the dialyzed solution in step e, left standing at 4°C for 10 hours, centrifuged to obtain a precipitate, and vacuum freeze-dried to obtain carboxymethylated rice bran polysaccharide with a degree of substitution of 0.68.

Embodiment 3

[0046] The difference with Example 1 is:

[0047] The ultrasonic treatment conditions in step d are: ultrasonic power 180W, ultrasonic time 15min, reaction temperature 40°C;

[0048] In step f, three times the volume of absolute ethanol was added to the dialyzed solution in step e, left standing at 4°C for 10 hours, centrifuged to obtain a precipitate, and vacuum freeze-dried to obtain carboxymethylated rice bran polysaccharide with a degree of substitution of 1.39.

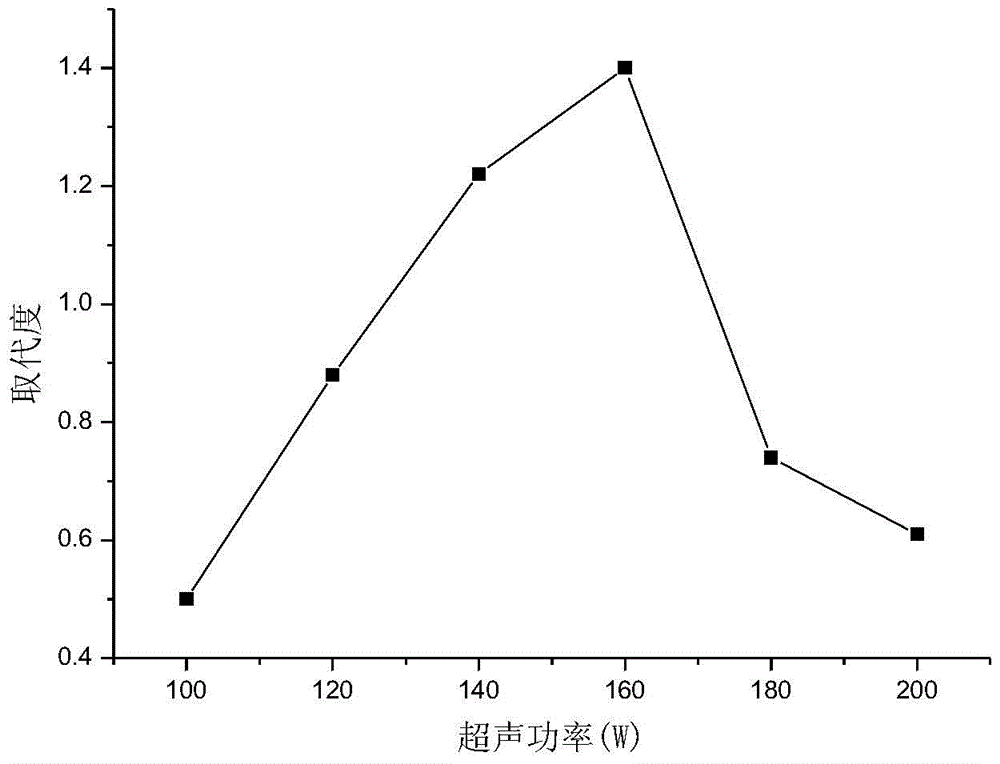

[0049] To the optimization of the optimal conditions of ultrasonic treatment in step d described in embodiment 1:

[0050] (1) Single factor experiment on ultrasound-assisted response

[0051] The influence of different power on the degree of substitution: under the conditions of reaction temperature of 60°C and reaction time of 20 minutes, the power of the ultrasonic wave is changed, and the power is respectively selected as 100W, 120W, 140W, 160W, 180W, and 200W. Through the determination of the degree of subs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com