An extended hanging basket for cantilever beam cast-in-place construction and its construction method

A cantilever beam and cast-in-place technology, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of inability to bind steel bars in the rear section of the box girder, fixed management of construction procedures, waste of time for box girder sections, etc. To achieve the effect of shortening the binding time of steel bars, shortening the construction period, and good engineering practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

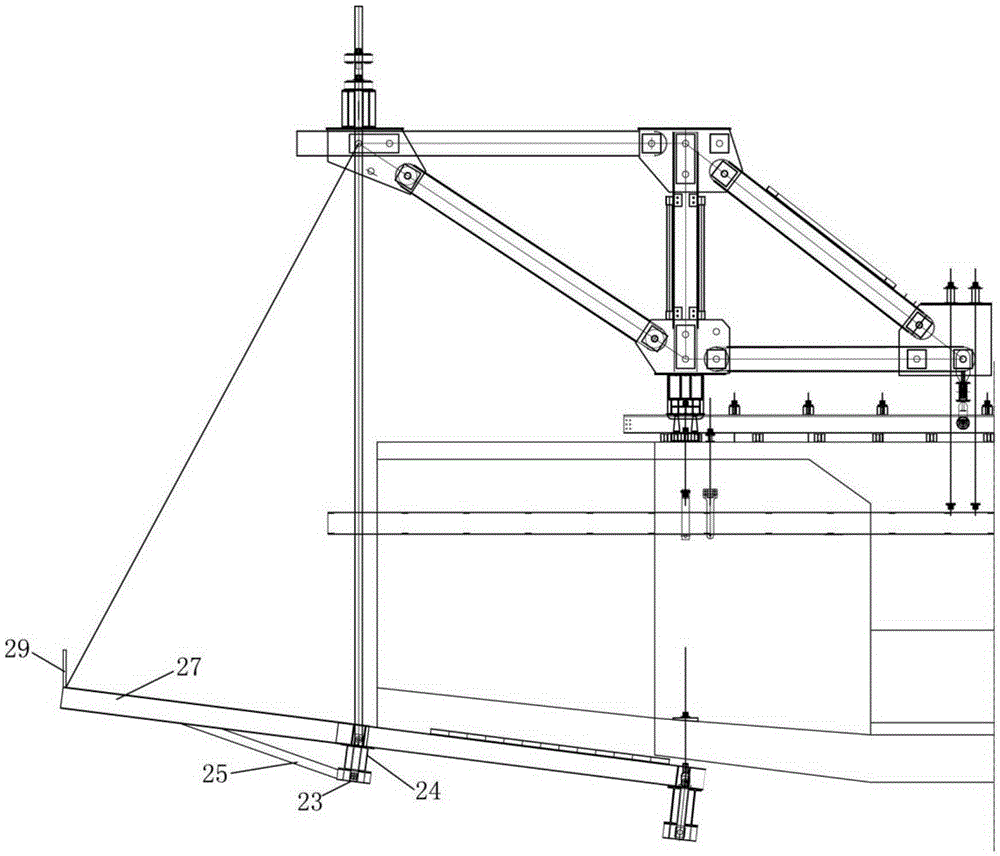

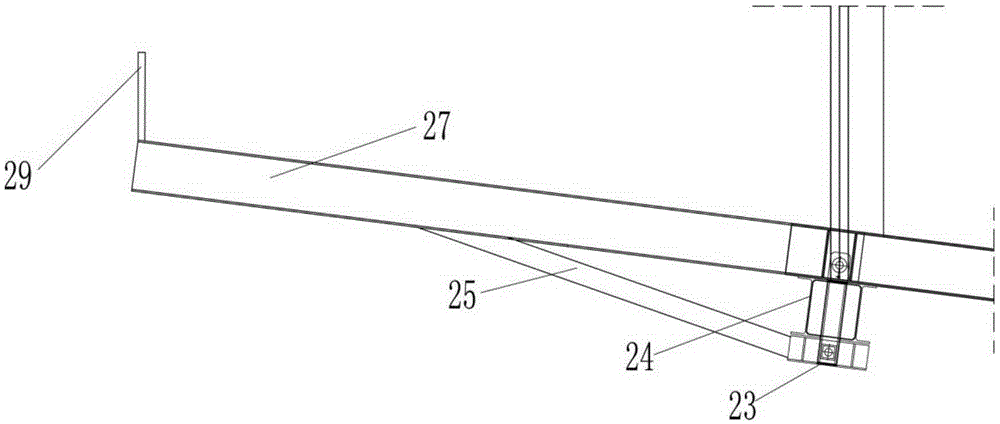

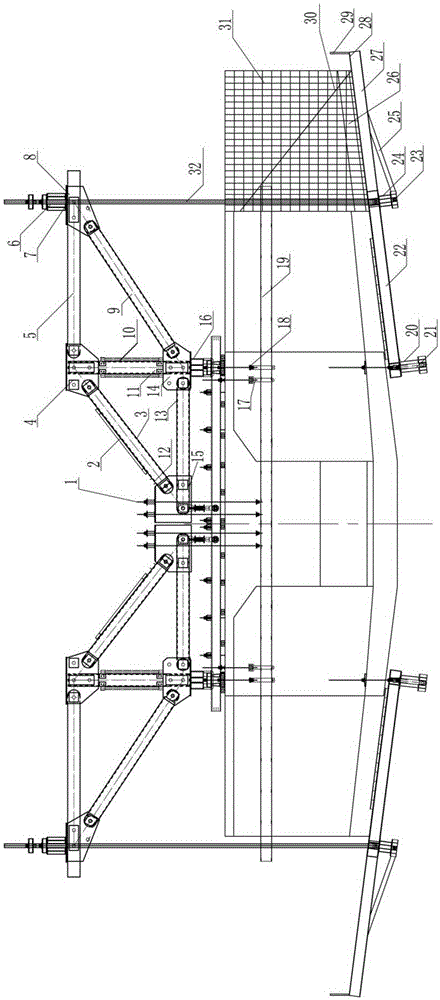

[0048] 1. Hanging basket extension

[0049] (1) Connect 22 channel steel to the lower beam in front of the hanging basket;

[0050] Weld 5m-long 22-channel steel in the I-beam slot of the lower beam in front of the hanging basket, with a spacing of 630-1100mm, a total of 20 pieces on one side, and the effective length of the long section is 4.5m.

[0051] (2) Set up the triangular support frame;

[0052] The position 2.25m away from the 22-channel steel at the long end is used as a node, and the beam hanger is used as a node, and the 2.4m-long 14-channel steel is welded as an oblique support, and each 22-channel steel is one piece.

[0053] (3) Set up guardrails.

[0054] Weld 1.6m long steel pipes around the outermost 22 channel steel with a spacing of 1.2m, set 2 horizontal bars, and then lay dense mesh.

[0055] 2. Lay the base plate formwork

[0056] (1) Bamboo plywood is laid on the cantilevered extension frame of the hanging basket;

[0057] (2) Bamboo plywood is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com