A prefabricated rc frame node with anti-drop beam energy dissipation device

An energy-consuming device and anti-falling beam technology, which is applied in the direction of earthquake resistance, protective buildings/shelters, building types, etc., can solve problems such as high cost, unconsidered falling beams, and many wet operations on site, so as to prevent pressure Unstability and deformation, reduction of construction waste, and effect of increasing pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

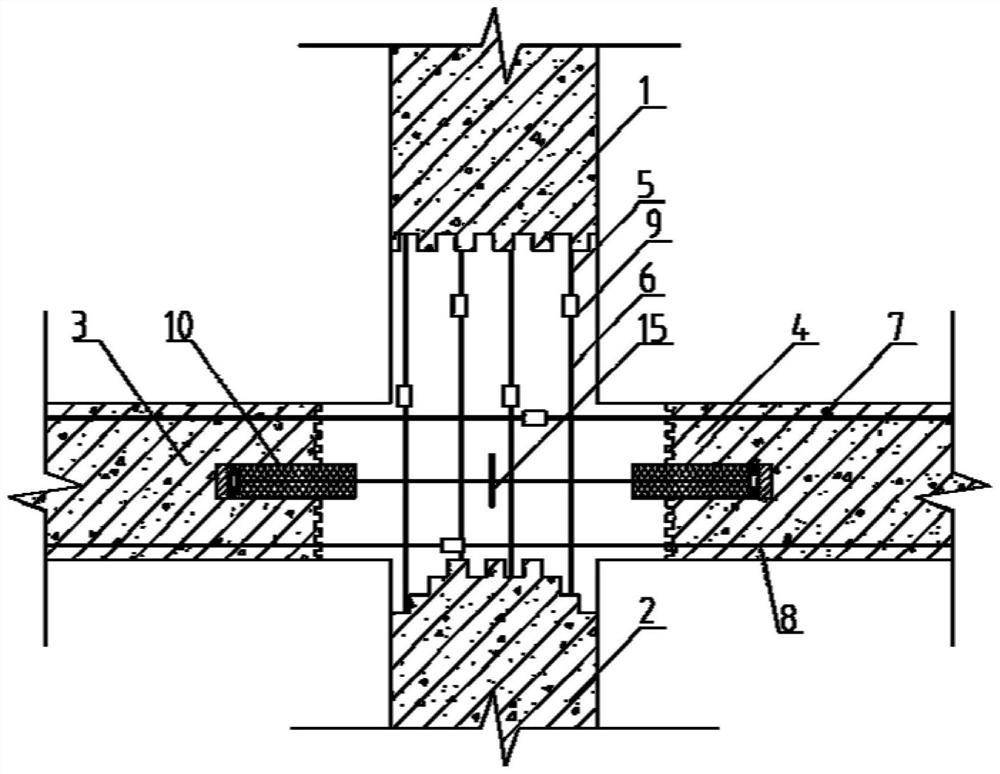

[0022] Such as Figure 1 to Figure 6 As shown, a prefabricated RC frame node with anti-fall beam energy dissipation device includes: precast concrete upper column 1, precast concrete lower column 2, precast concrete left beam 3, precast concrete right beam 4 and anti-fall beam energy dissipation device 10. Among them, the built-in anti-fall beam energy dissipation devices 10 in the left and right beams are connected by steel cables 13, and the end steel plates are arranged in the middle of the steel cables; the beams and columns are respectively connected by steel sleeves to reserve longitudinal reinforcement.

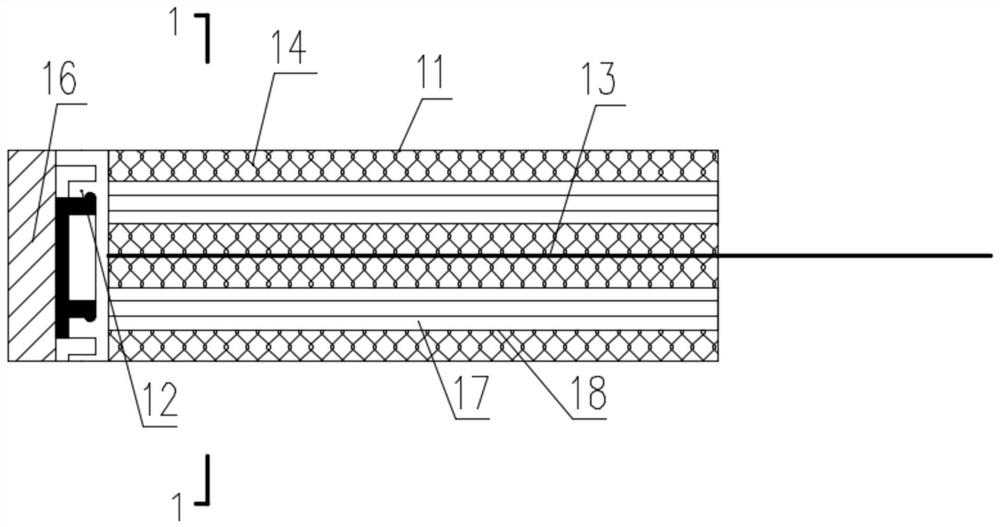

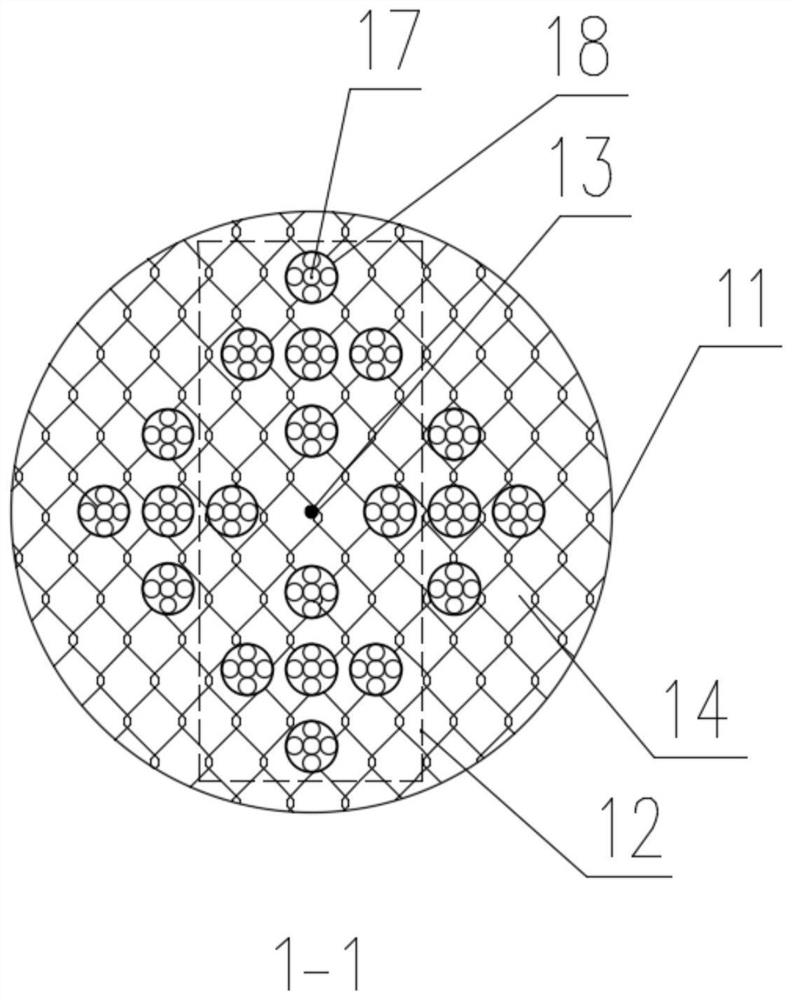

[0023] Built-in anti-fall beam energy dissipation device 10, including: built-in rigid casing 11, buckle 12, memory alloy ball 14, buckle steel plate 16, anti-fall beam memory alloy column 17, thin-walled fixing sleeve 18; built-in rigid casing 11. The material is hard steel, which are partially pre-embedded in the precast concrete left beam 3 and the precast concrete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com