Square prefabricated reinforced concrete culvert

A reinforced concrete and concrete technology, applied in the field of culverts, can solve the problems of long time for concrete solidification, uneven quality of finished products, and unguaranteed safety, etc., and achieve the effect of convenient construction, fewer assembly steps, and quick pipe formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

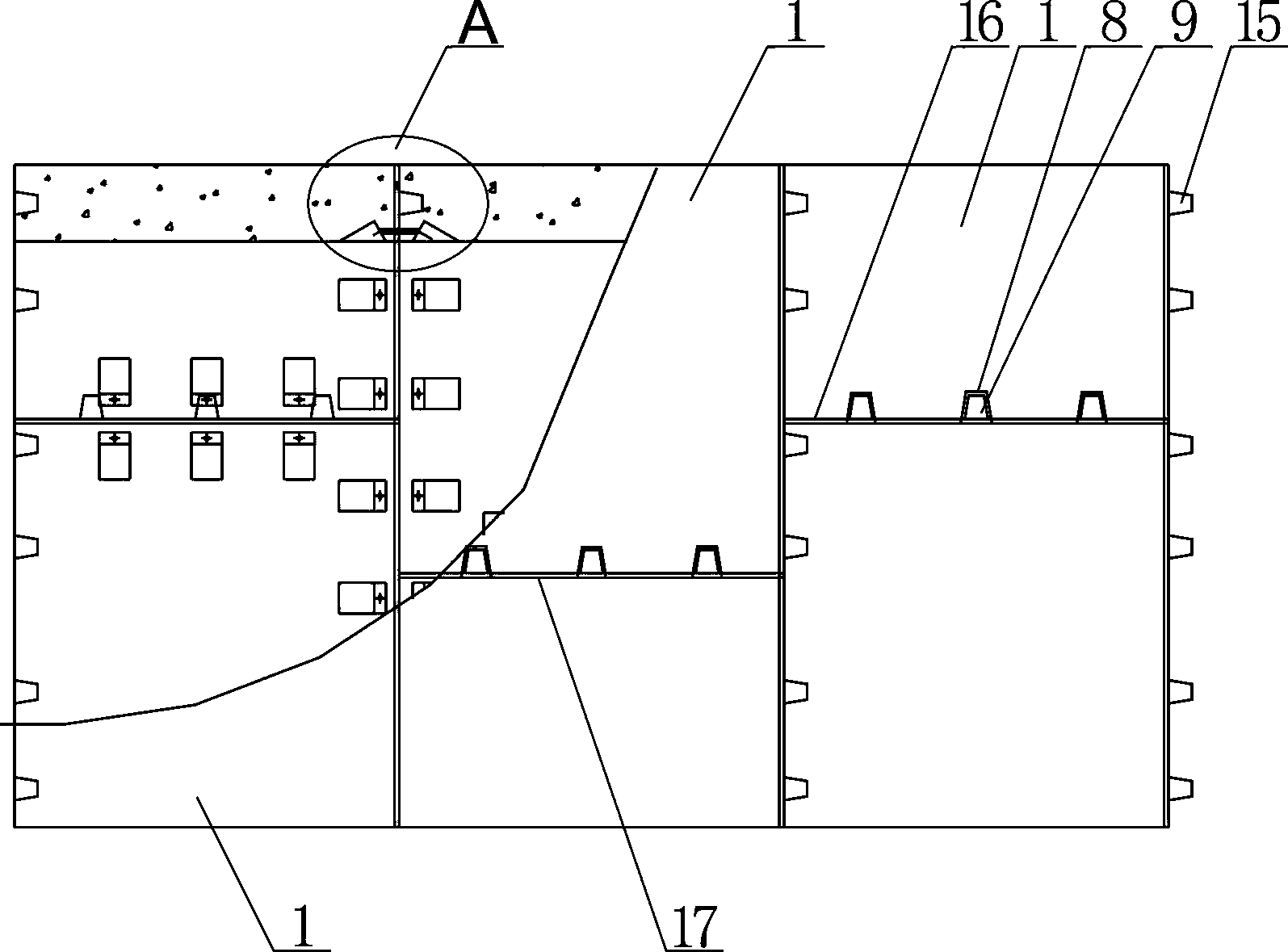

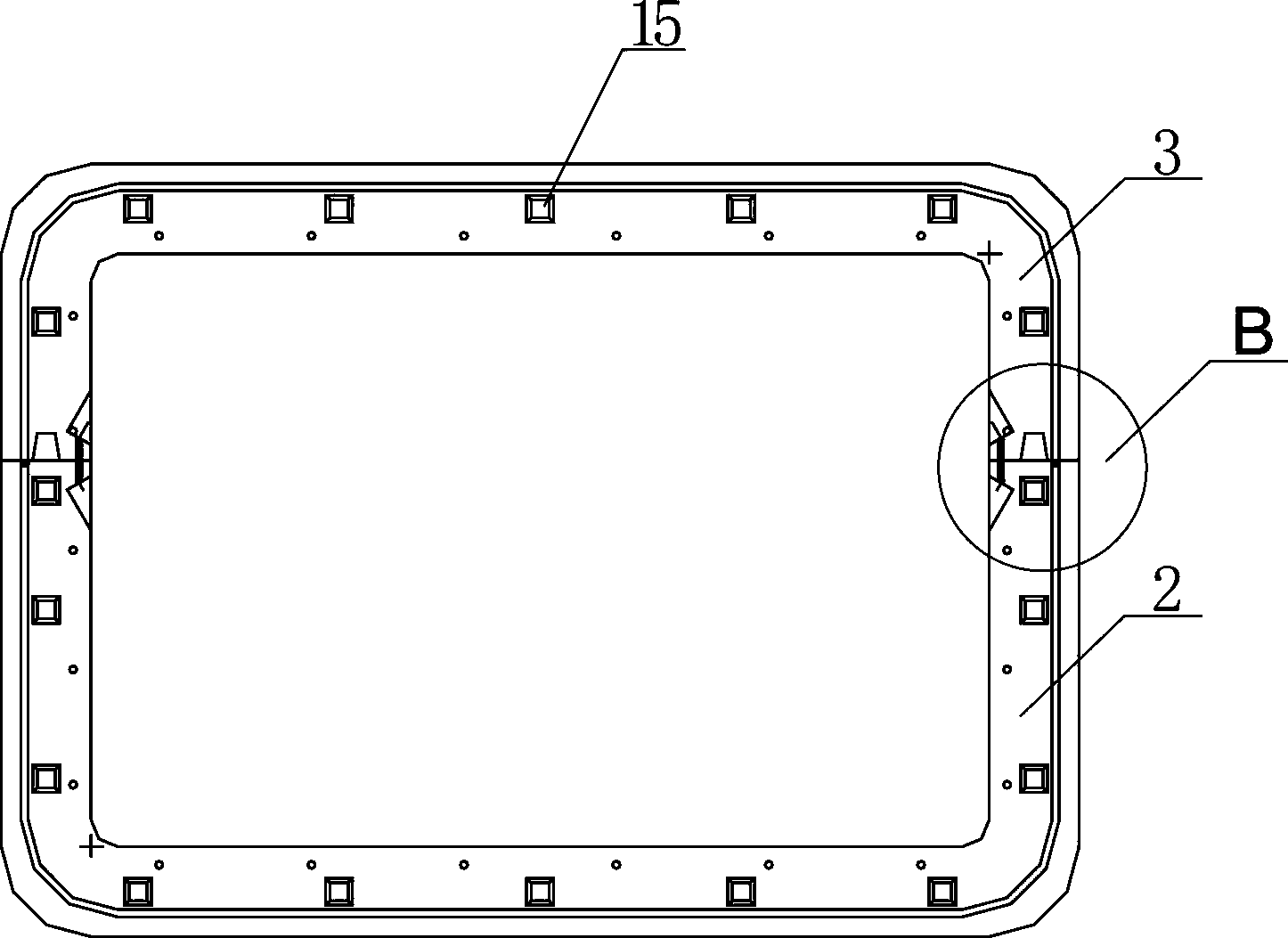

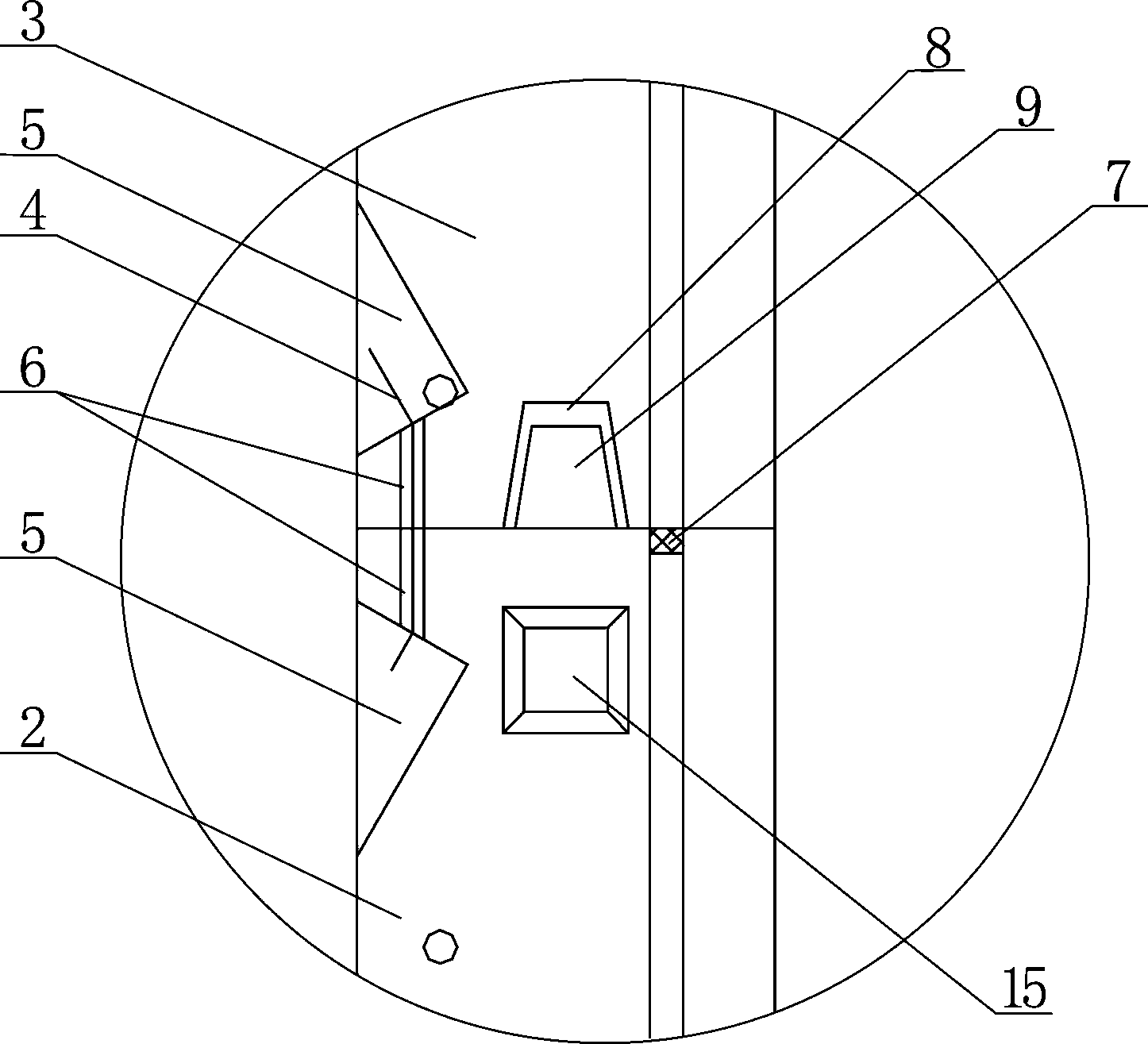

[0024] Such as figure 1 , 2 3, the reinforced concrete prefabricated square culvert is formed by butting multiple sections of prefabricated concrete pipes 1. The cross section of the prefabricated concrete pipes 1 is square, and each section of prefabricated concrete pipe 1 is composed of a large half tank 2 and a small half The trough body 3 is connected by an arc-shaped transverse bolt 4. On the inner wall of the major half trough body 2 and the smaller half trough body 3 and close to the connection between the major half trough body and the small half trough body, a plurality of grooves 5 are distributed correspondingly at intervals. The groove 5 is a V-shaped groove. A through hole 6 is provided on the side wall of the groove 5 near the connection point, and the arc-shaped transverse bolt 4 is penetrated in the opposite through hole on the large half groove body 2 and the small half groove body 3. A sealing strip 7 is provided at the junction of the large half tank and the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap