Double-tuned liquid column damper

A damper and liquid technology, applied in the direction of building components, shockproof, etc., can solve the problem that the control effect is not as good as TMD, etc., and achieve the effect of simple installation, large economic and social benefits, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in combination with technical solutions and with reference to the accompanying drawings.

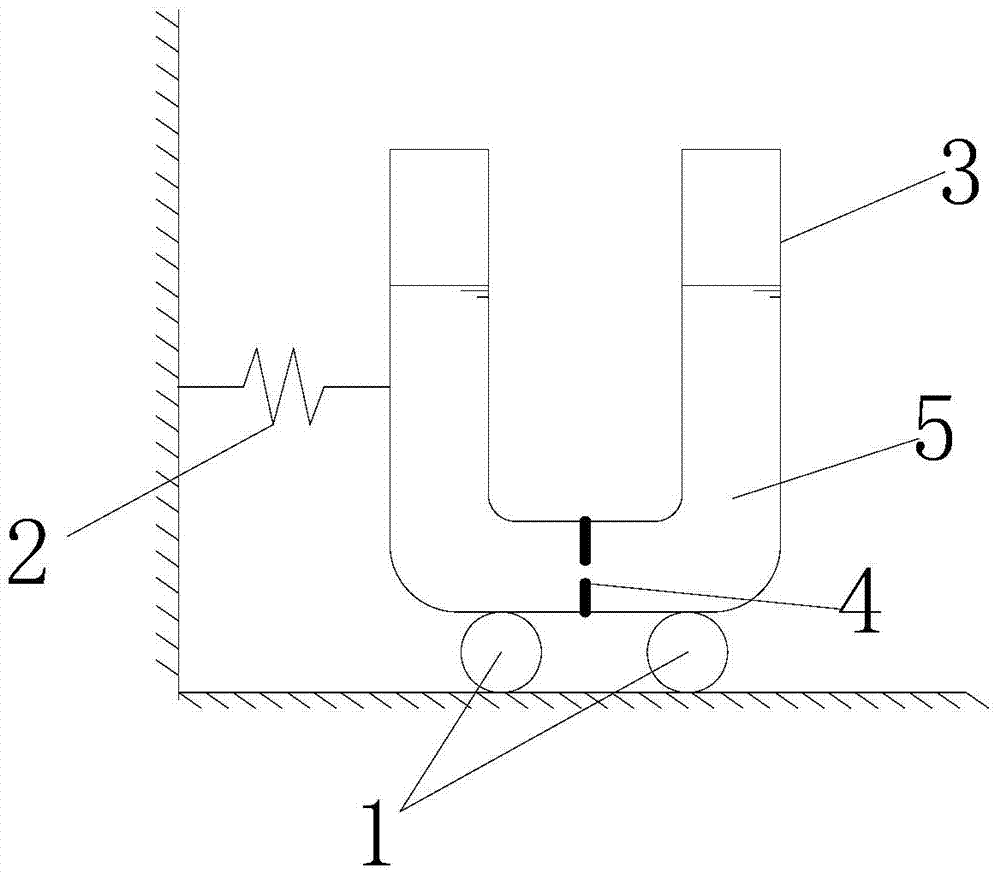

[0015] The double-tuned liquid cylindrical damper proposed by the present invention is as figure 1 shown.

[0016] The whole device is mainly composed of a lower horizontal sliding device 1, a lower horizontal spring 2, a U-shaped water tank 3, a water tank damping hole 4 and an appropriate amount of water tank liquid 5 and the like. One end of the lower horizontal spring 2 is connected to the structure, and the other end is connected to the U-shaped water tank 3, which has the function of self-resetting of the water tank; The structural vibration direction slides horizontally; the water tank damping hole 4 is set in the middle of the U-shaped water tank 3 horizontal pipe, and when the liquid 5 in the U-shaped water tank 3 passes through the water tank damping hole 4 when the water tank shakes, damping will be generated to d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com