Double-layer hollow concrete slab wall and its construction method

A double-layer hollow, concrete slab technology, applied in the direction of formwork/formwork/work frame, wall, building components, etc., can solve the problems of inconvenient formwork erection, reducing the utilization rate of construction materials, affecting the sound insulation effect of sandwich walls, etc. Dismantling, meeting the requirements of sound insulation, and the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

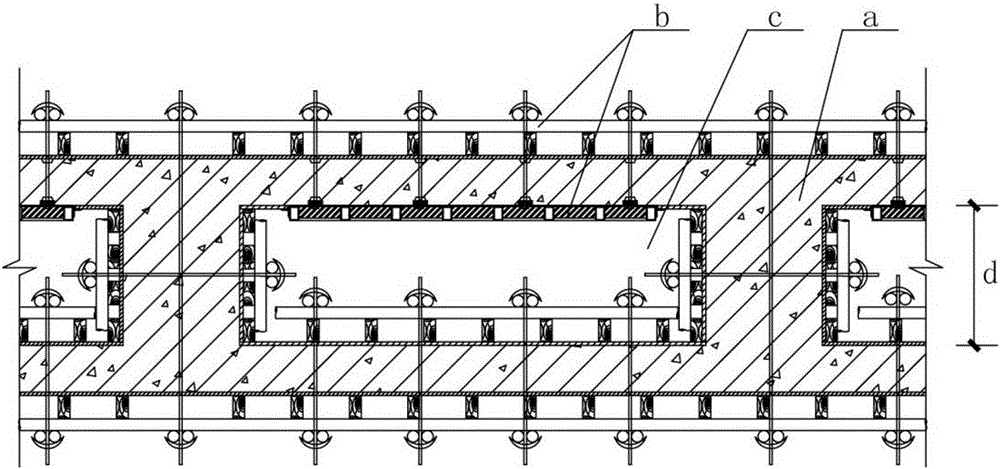

[0031] Example 1: Combination Figure 7 Explain that the double-layer hollow concrete slab wall of the present invention is formed by connecting several construction units. This embodiment takes a construction unit as an example to describe its structure and composition in detail. The construction unit includes two parallel and spaced concrete Slab 1; two ring beams connected between the two concrete slabs 1, namely the bottom ring beam 3 and the top ring beam 5; the two concrete slabs 1, the bottom ring beam 3 and the top ring beam 5 together form a closed Cavity 6'; among them, the bottom ring beam 3 is composed of the prefabricated slab compartment 1-2 connected between the two concrete slabs 1 and the concrete members cast on the prefabricated slab compartment 1-2, and the top ring beam 5 is connected by The prefabricated slab compartment 2 4 between the two concrete slabs 1 and the concrete components poured on the prefabricated slab compartment 2 4 are composed.

[0032] Th...

Embodiment 2

[0036] Embodiment 2: Combination Figure 2 to Figure 7 To illustrate the construction method of the double-layer hollow concrete slab wall of the present invention, the specific steps are as follows:

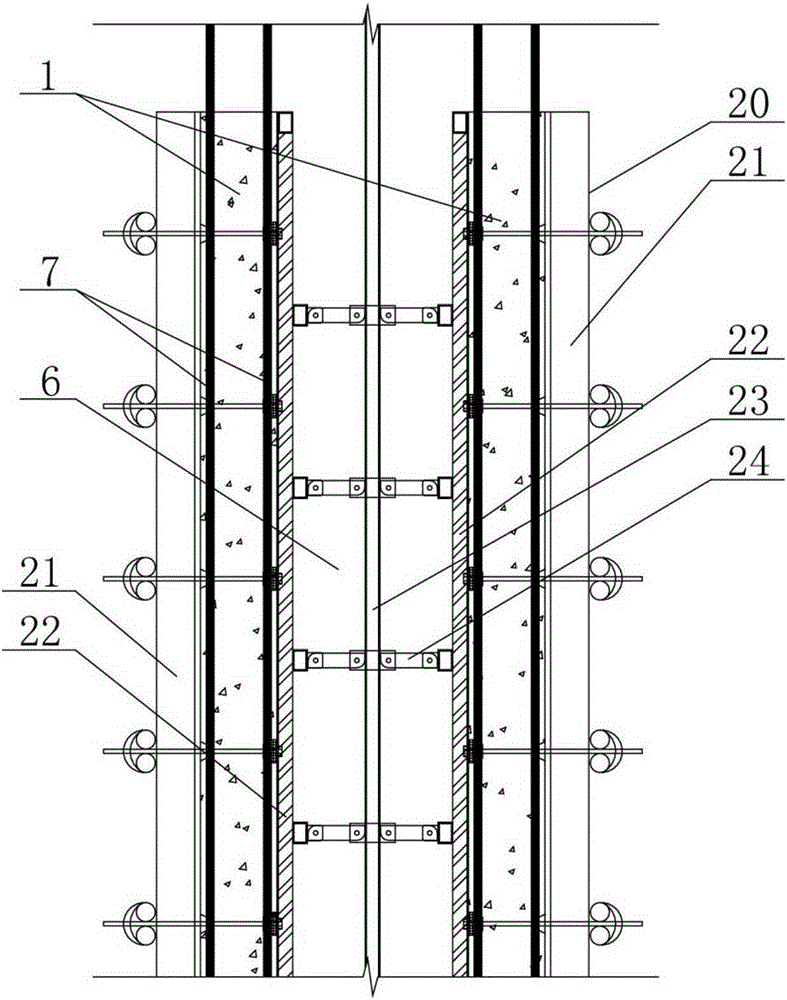

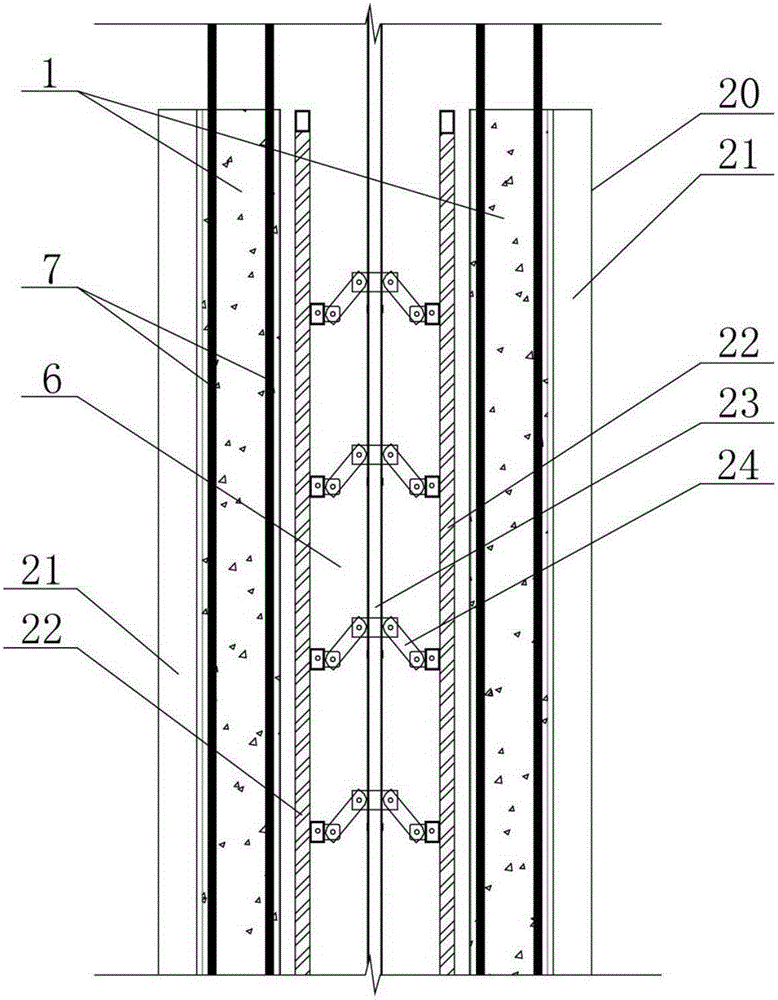

[0037] S101: Such as figure 2 with image 3 As shown, a formwork system 20 with two concrete slabs 1 is set up, and embedded steel bars 7 are set in the formwork system 20 and concrete is poured. After the concrete reaches the design strength, the formwork system 20 is removed to obtain the concrete slab 1;

[0038] S102: Such as Figure 4 As shown, between the two concrete slabs 1 produced in step S101, the prefabricated slab compartment 1-2 is horizontally arranged. Specifically, the prefabricated slab compartment 1-2 is fixed to the pre-embedded steel bars extending from the top of the concrete slab 1. 7, and enable the prefabricated slab compartment 1 2 to cover the cavity 6 between the two concrete slabs 1;

[0039] S103: Such as Image 6 As shown, with the prefabricated slab co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com