Large Slope Rock Drilling Machine

A large slope, roadheader technology, applied in the direction of propulsion, cutting machinery, slitting machinery, etc., can solve the problems of incomplete loading of coal and rock, waste of coal and rock, insufficient traction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

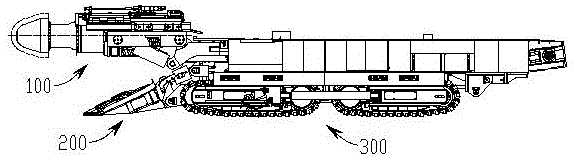

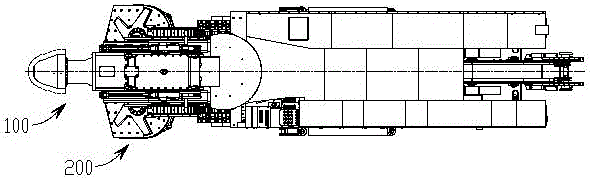

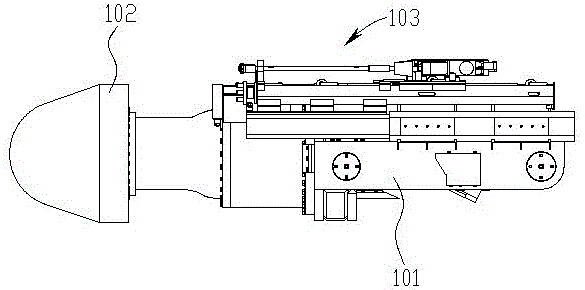

[0022] see first figure 1 , figure 2 , the large slope rock drilling machine of the present invention has a cutting part 100, a shovel part 200 and a walking part 300; see again image 3 - Figure 7 , the cutting part 100 includes a cutting bracket 101 and a cutting head 102 mounted on the cutting bracket 101; The side blades 202 on both sides, the middle and rear part of the main blade 201 are provided with a chute 203, and the side blades 202 are equipped with a star wheel 204; The crawler belt assembly 304, the walking part 300 also includes a leg member mounted on the side wall of the walking frame 301 and can be plunged into the ground; The shovel telescoping mechanism 205 on the outside. The side blade telescopic mechanism 205 has a telescopic blade 206, the middle rear part of the telescopic blade 206 is connected with the middle rear part of the side blade 202 through a first pin shaft 207, and is close to the rear end of the telescopic blade 206 Through the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com