Rolling bearing cage or segment for rolling bearing cage

A technology for rolling bearings and cages, applied in the field of rolling bearing cages or sections used for rolling bearing cages, can solve the problems of reducing the lubricating performance of lubricating materials, heating and damage of lubricating material rolling bearings, etc., and achieve good deformation, simple manufacturing, and simple fill effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

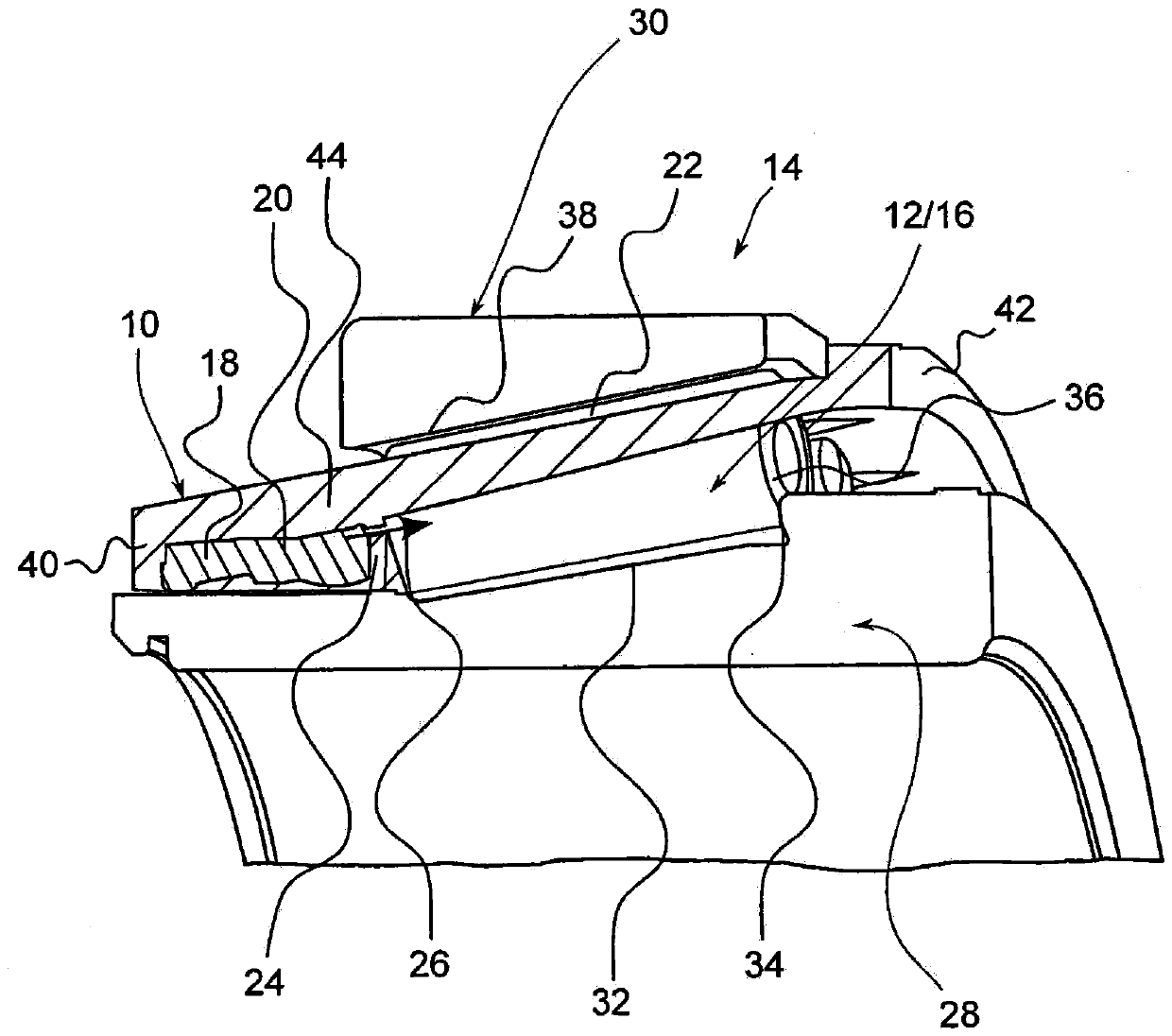

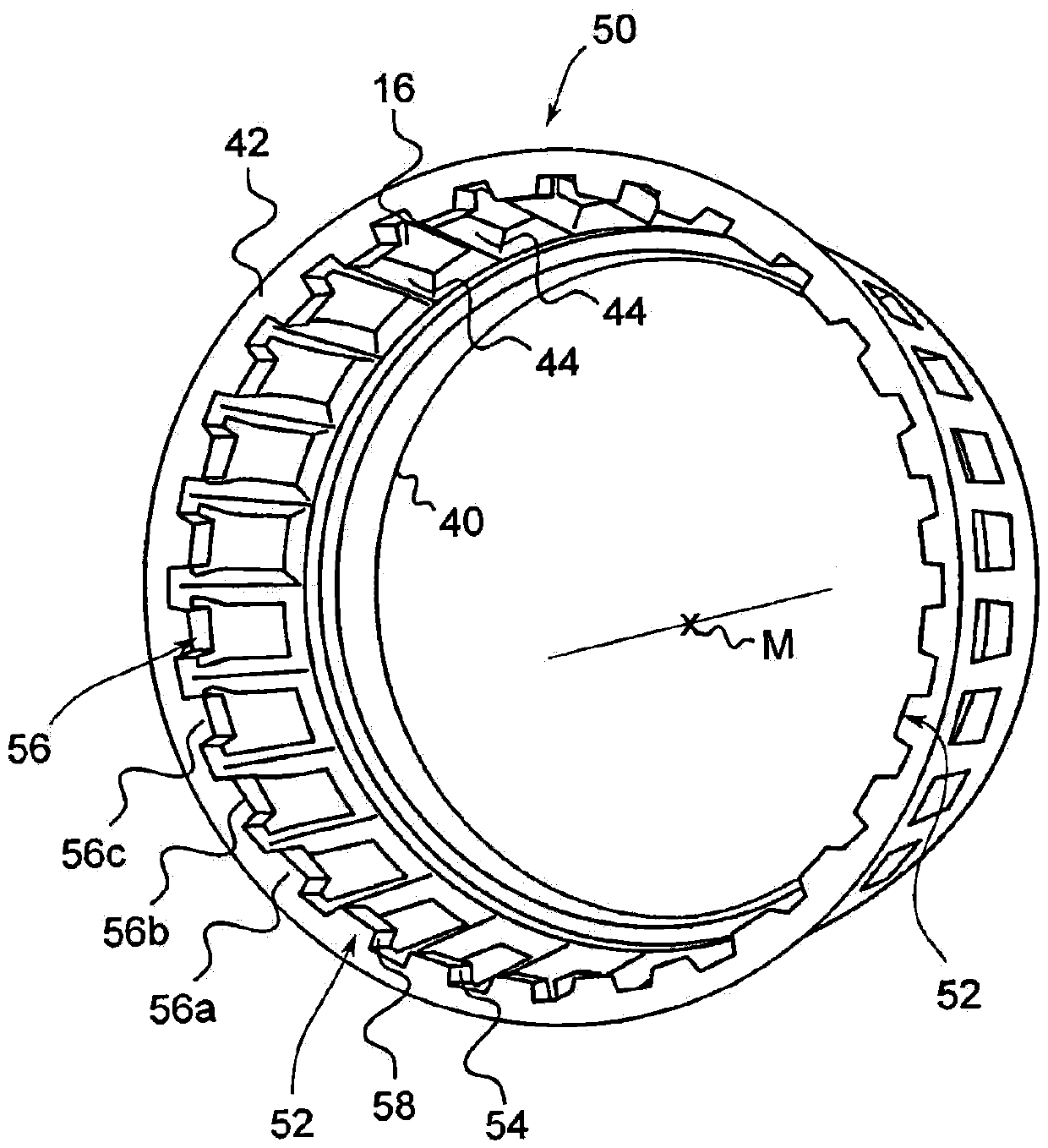

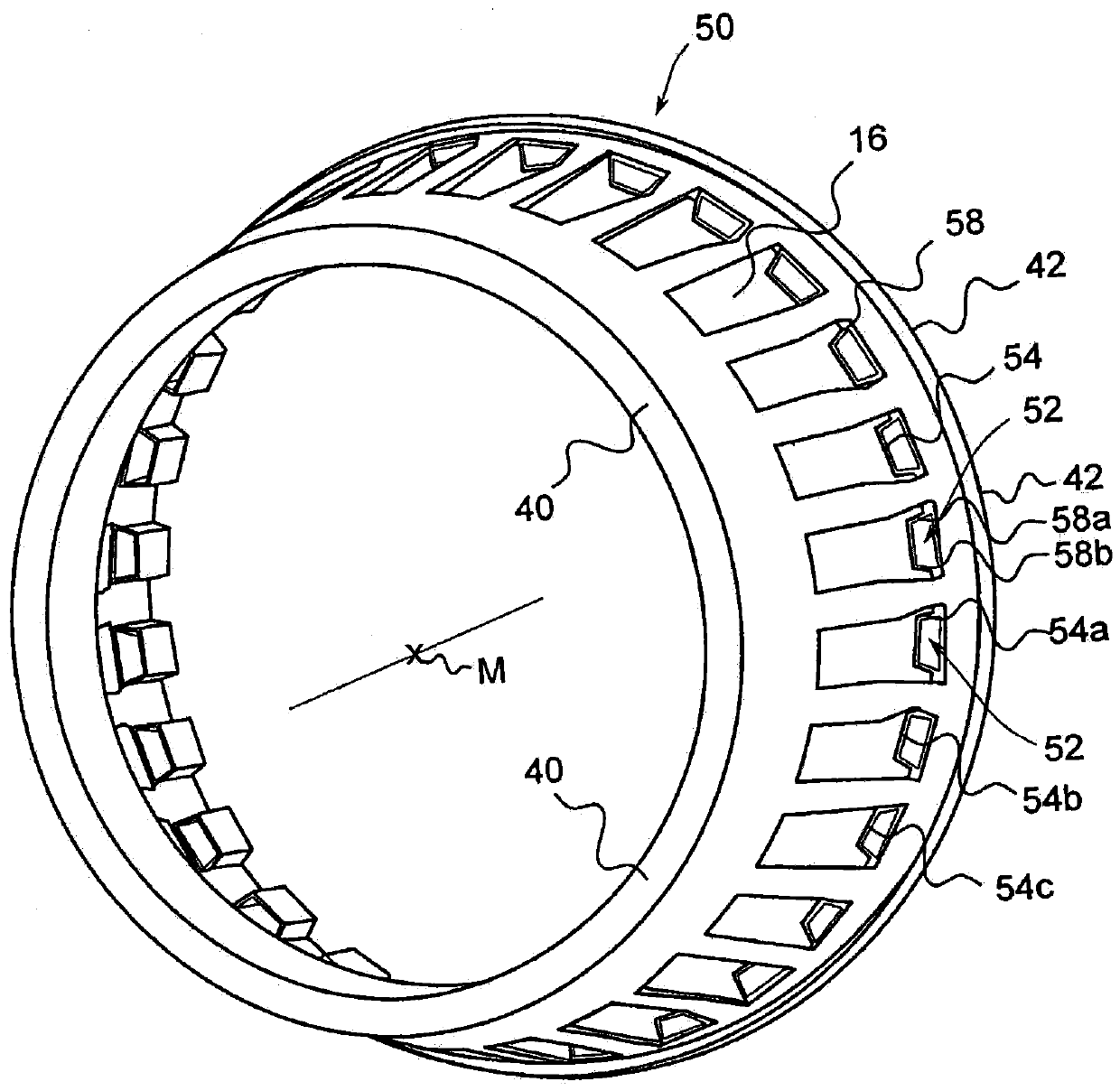

[0038] Various embodiments will now be explained in detail with reference to the accompanying drawings, in which some embodiments are shown. The thickness dimensions of lines, layers and / or regions in the drawings are exaggerated for clarity of illustration.

[0039] The following description of the drawings merely shows some exemplary embodiments, where like reference numerals designate like or similar elements. In addition, summative reference signs are used for elements and objects, which occur several times in the exemplary embodiment or illustration but describe one or more features together. One, several or all features of elements or objects identified by the same reference numerals, for example their dimensions, may be identical, but if necessary also be designed differently, provided that no other explicit conclusions are drawn from the description Or implied understanding.

[0040] Although the embodiments may be modified and changed in various ways, the embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com