relief valve

A technology for relief valves and slide valves, which is applied in the direction of safety valves, balance valves, valve devices, etc., and can solve the problem of inability to close the valve core of the slide valve, damage the pressure setting function of the relief valve, and the inability to stably control the pressure oil pressure and other problems to achieve the effect of suppressing the residual pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

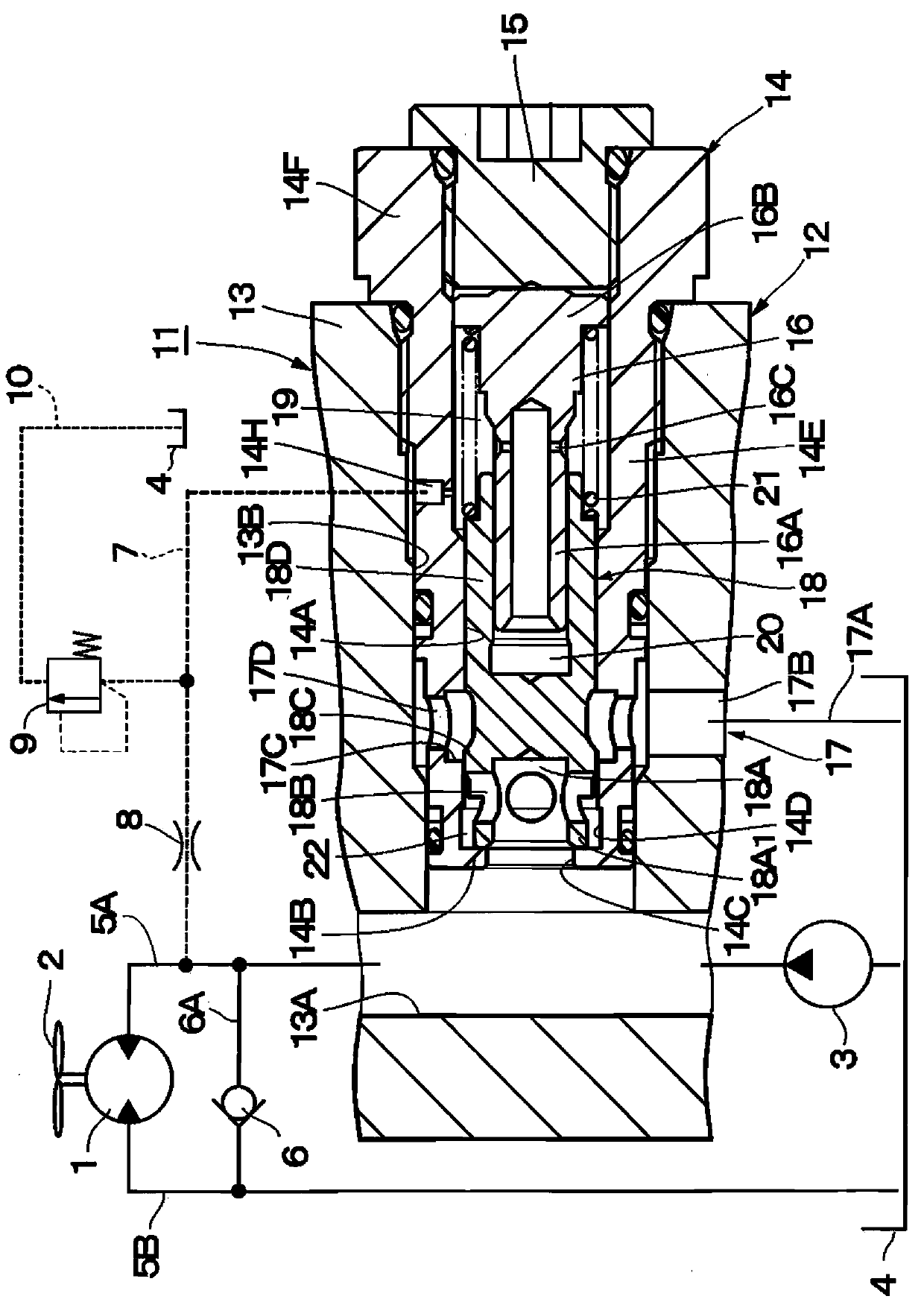

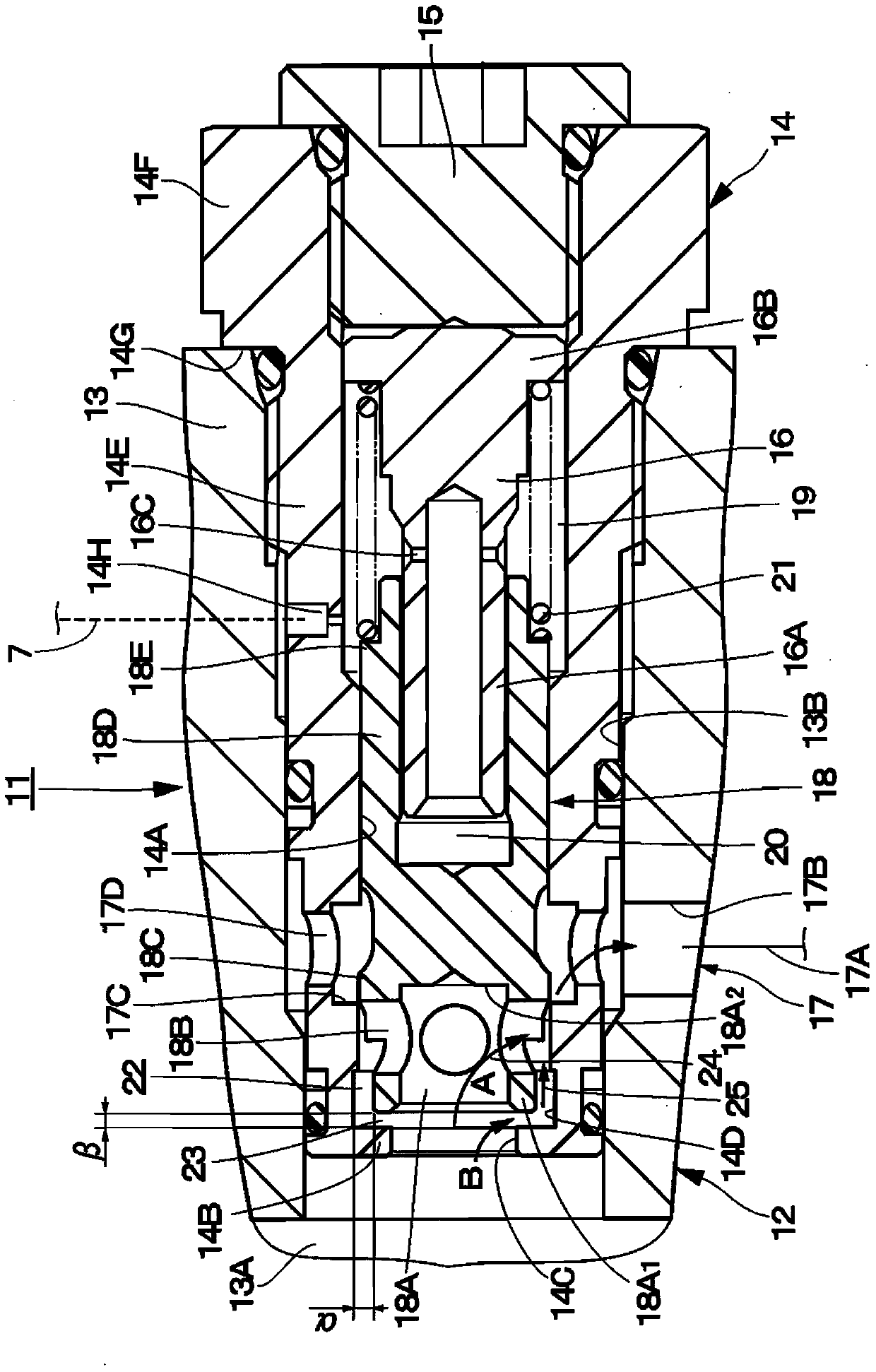

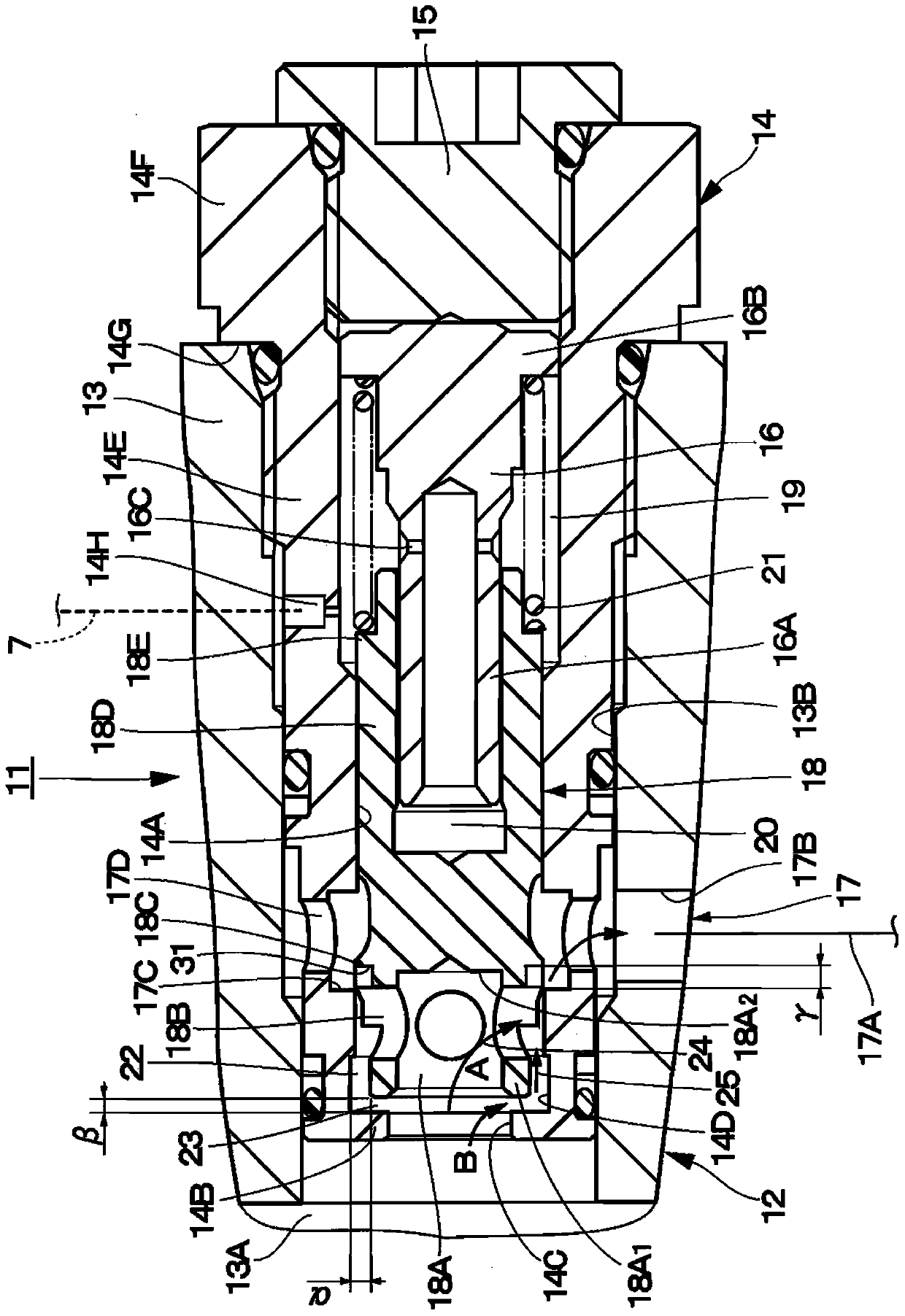

[0030] Below, refer to Figure 1 to Figure 6 The accompanying drawings will describe the relief valve in detail by taking the case where the relief valve according to the embodiment of the present invention is used in a drive circuit of a fan motor as an example.

[0031] here, figure 1 as well as figure 2 The first embodiment of the present invention is shown. In the figure, 1 is a fan motor as a hydraulic transmission device, and the fan motor 1 is composed of a hydraulic motor, and drives the cooling fan 2 to rotate. A construction machine represented by a hydraulic excavator is provided with heat exchangers such as a radiator for cooling engine cooling water and an oil cooler for cooling working oil (none of which are shown), and the cooling fan 2 supplies heat to the heat exchanger. cooling wind.

[0032]In addition, the heat exchanger provided in the construction machine is not limited to the above-mentioned radiator and oil cooler, and may include, for example, an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com