Small chassis mobile lng filling skid

A chassis and filling machine technology, applied in the field of LNG filling skid, can solve problems such as failure, difficult rescue, and long impact time, and achieve the effects of reducing the increase in LNG gasification, saving energy, and reducing pump wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

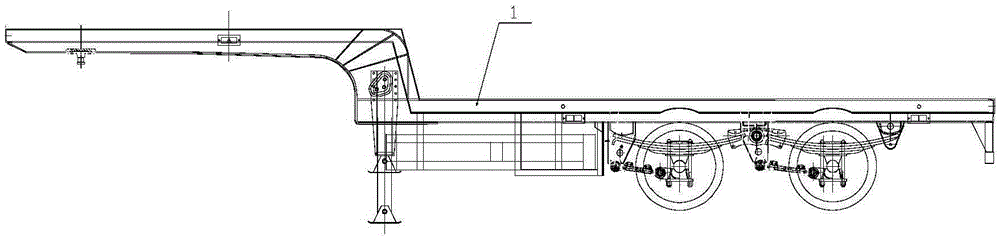

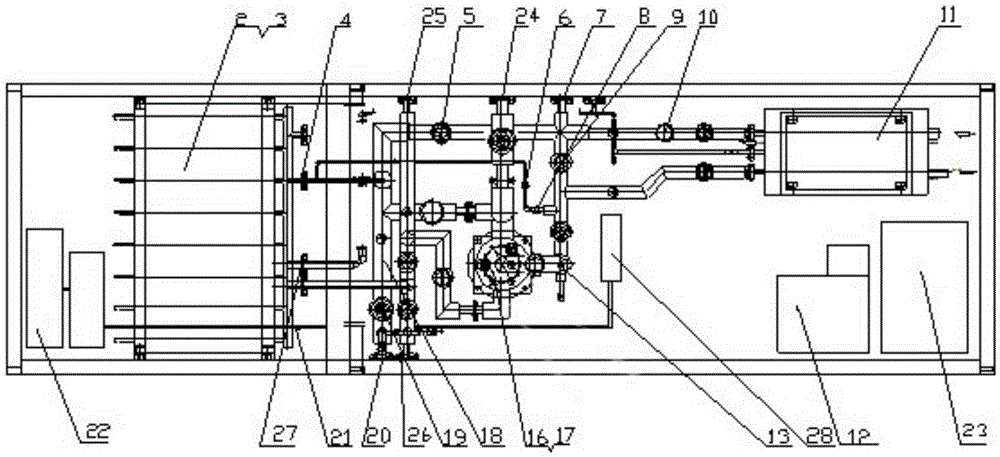

[0008] Such as figure 1 , 2 As shown, a filling machine 11, an explosion-proof electrical cabinet 12, a booster 2, an EAG heater 3, an explosion-proof air compressor 22, a pump pool 16, a submersible pump 17, a vacuum pipeline system 18, and an air compressor are fixed on a small chassis 1. Air pipeline system 21, filling machine electrical system 23 and pneumatic solenoid valve group 28. The filling machine electrical system 23 and the filling machine 11 constitute a filling system. The supercharger liquid inlet 4 is in sealing communication with the liquid phase port 20 of the tank truck, the liquid phase port 24 of the storage tank, and the liquid outlet port 13 of the submersible pump respectively, and the liquid outlet of the supercharger 2 is connected with the gas phase port 25 and the gas phase port of the storage tank respectively. The gas port 26 of the tank car is sealed and communicated to form a pressurization system. The inlet 27 of the EAG heater 3 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com