Antifreeze method of casing heat exchanger

A technology of heat exchanger and casing type, which is applied in the field of antifreeze of casing type heat exchangers, which can solve the problems of casing and refrigerant pipes that are easy to freeze and crack, and achieve good ductility and avoid freezing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

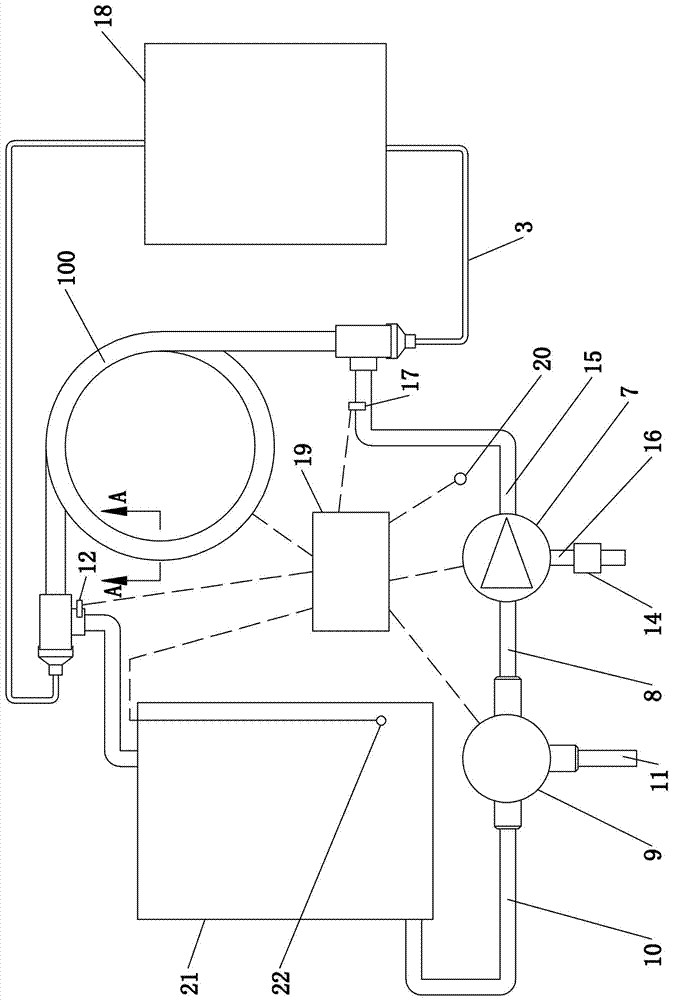

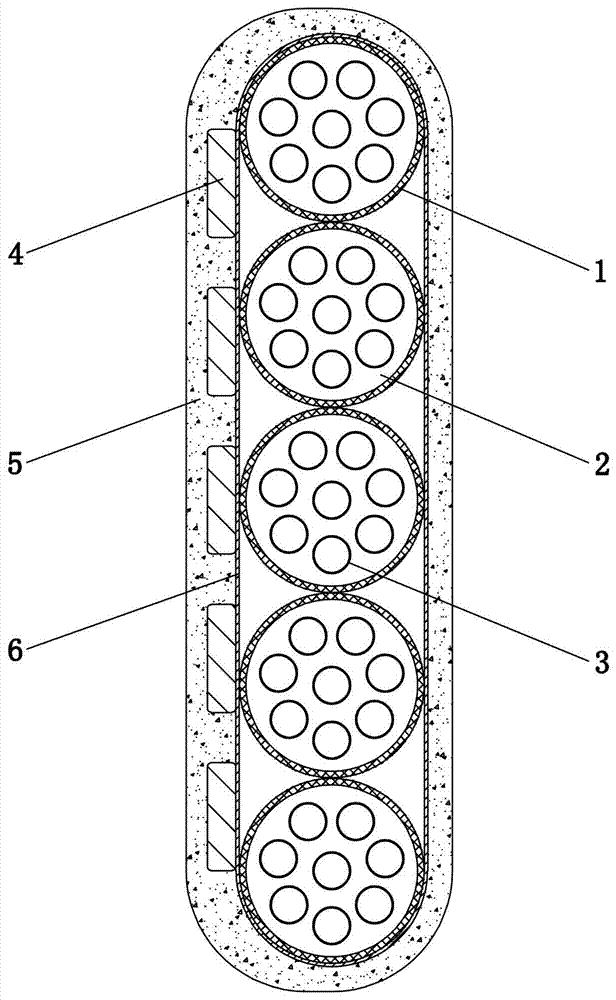

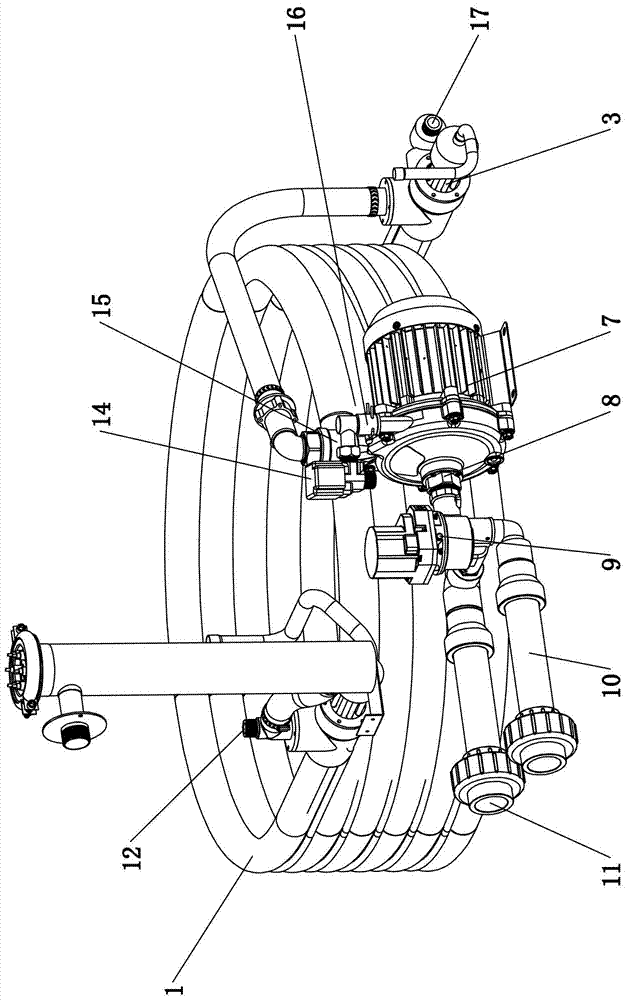

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0025] see Figure 1 to Figure 3 As shown, a casing heat exchanger 100 antifreeze structure includes a refrigerant pipe 3, a casing 1, a water storage tank 21 and a control circuit 19. The refrigerant pipe 3 is arranged in the casing 1, and the outer wall of the refrigerant pipe 3 is connected to the casing 1 The water heating chamber 2 is jointly surrounded by the inner walls, and one end of the water heating chamber 2 communicates with the water storage tank 21; it is characterized in that: it also includes a circulating water pump 7 electrically connected to the control circuit 19, an outdoor temperature sensor 20 and a water level switch 22; The circulating water pump 7 is provided with a water inlet 8 and a water outlet 15, and the water inlet 8 is respectively connected with the water inlet pipe 11 and the water storage tank 21 through the electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com