Method for controlling size of boiling liquid bubbles

A technology of bubbles and liquids, which is applied in the field of controlling the size of liquid boiling bubbles, and achieves the effects of novel structure, extensive scientific and application value, and unique methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

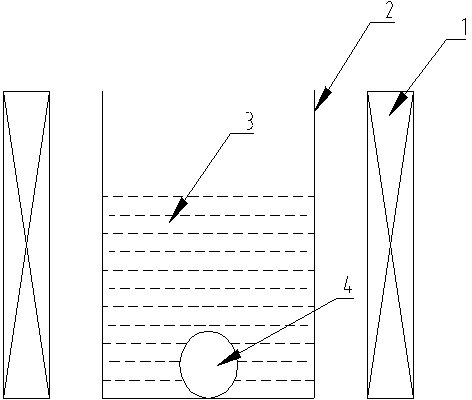

[0013] Such as figure 1 Shown, a kind of method of controlling liquid boiling bubble size, comprises the following steps:

[0014] a. The magnetic field generating device 1 is symmetrically arranged on both sides of the container 2, and the boiling liquid 3 is placed in the container 2;

[0015] b. The magnetic field generating device 1 generates a gradient magnetic field, and adjusts the gradient direction of the gradient magnetic field. When the gradient direction of the gradient magnetic field generated by the magnetic field generating device 1 is the same as the direction of gravity of the boiling liquid 3, the boiling liquid 3 is subject to the same magnetic force as the direction of gravity. , due to the combined action of the resultant force, the desorption size of the bubbles in the boiling liquid 3 becomes smaller, and the bubbles quickly desorb from the heating surface, which enhances the efficiency of boiling heat transfer. The larger the gradient of the gradient ...

Embodiment 2

[0018] The embodiment of this embodiment is basically the same as that of Example 1, the difference is that:

[0019] In this embodiment, the magnetic field generating device 1 is powered by an AC power supply, and the boiling liquid 3 is oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com