Heat exchange tube, manufacturing method of heat exchange tube and heat exchanger with heat exchange tube

A technology of heat exchange tubes and tubes, which is applied in the field of heat exchange, and can solve problems such as poor heat exchange efficiency, increased gas impedance, and fast passing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

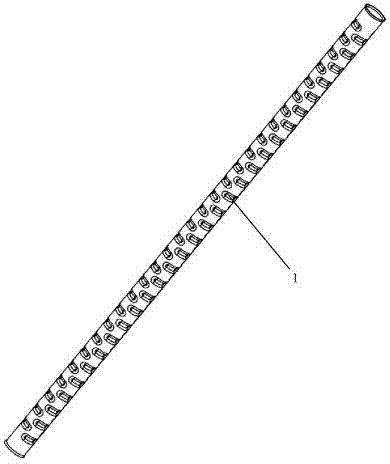

[0021] Such as figure 1 As shown, the present invention provides a heat exchange tube. Four rows of arc-shaped grooves are pressed on the surface of the heat exchange tube along the length direction. Each row of arc-shaped grooves is at the same horizontal position. The arc length of the arc-shaped grooves 0.25 times the circumference of the heat exchange tube section, the depth is 0.15-0.25 times the diameter of the heat exchange tube section circle, and the width is 0.15-0.25 times the heat exchange tube section circle diameter. The circumferential direction of the tube is staggered by 90 degrees, the distance between two adjacent arc-shaped grooves on the same row of arc-shaped grooves is equal to the diameter of the cross-sectional circle of the heat exchange tube, and the stagger between two adjacent rows of arc-shaped grooves is 0.5 times The cross-sectional diameter of the heat exchange tube.

Embodiment 2

[0023] A method of manufacturing a heat exchange tube, comprising the steps of:

[0024] (1) Fix the circular through pipe, and clamp both ends of the circular through pipe with the clamping device;

[0025] (2) Press the first row of arc-shaped grooves, start to press the arc-shaped grooves from the length of 1 times the diameter at one end of the circular through-pipe, and press the arc-shaped groove along the circumferential direction of the circular through-pipe. 0.25 times, the depth of the arc groove is 0.15-0.25 times the diameter of the cross-section circle of the circular through pipe, the width of the arc groove is 0.15-0.25 times the diameter of the cross-section circle of the circular through pipe, the distance between the arc grooves 0.5-1.5 times the circular diameter of the cross-section of the circular through pipe, and the other end of the circular through pipe has at least 1 times the diameter of the length of the unpressed area;

[0026] (3) Rotate the clam...

Embodiment 3

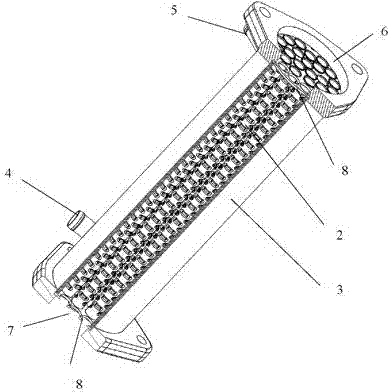

[0032] A heat exchanger, comprising, the heat exchange tube manufactured by the present invention, the shell, the water inlet pipe, the drain pipe, the air inlet, the air outlet and two tail plates, the two ends of the shell are respectively provided with a water inlet and a water outlet, A circular through hole with a diameter equal to the diameter of the heat exchange tube is opened on the end plate, and the two ends of the heat exchange tube are respectively sealed and welded to the circular through holes at the same position of the two end plates, and the two end plates are respectively sealed and fixed on the inlet. At the air port and the air outlet, the water inlet pipe and the water outlet pipe respectively seal the water inlet and the water outlet welded on the shell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com