Precision spindle test run device capable of simulating working conditions

A technology of working conditions and spindles, which is applied in the field of performance testing of machine tool spindles, and can solve problems such as spindle testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the content of the invention, features and effects of the present invention, the following embodiments are exemplified and described in detail with the accompanying drawings as follows:

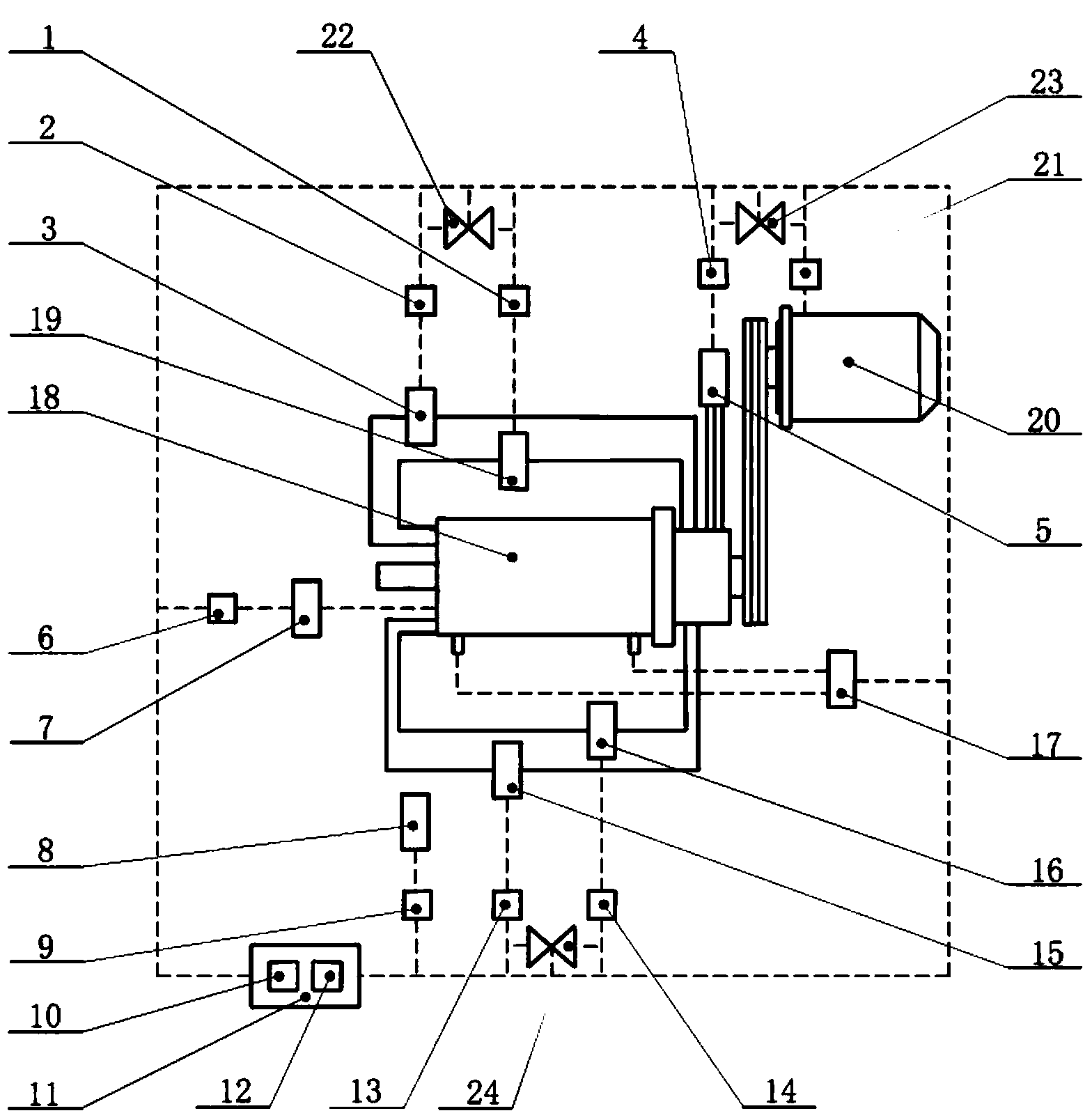

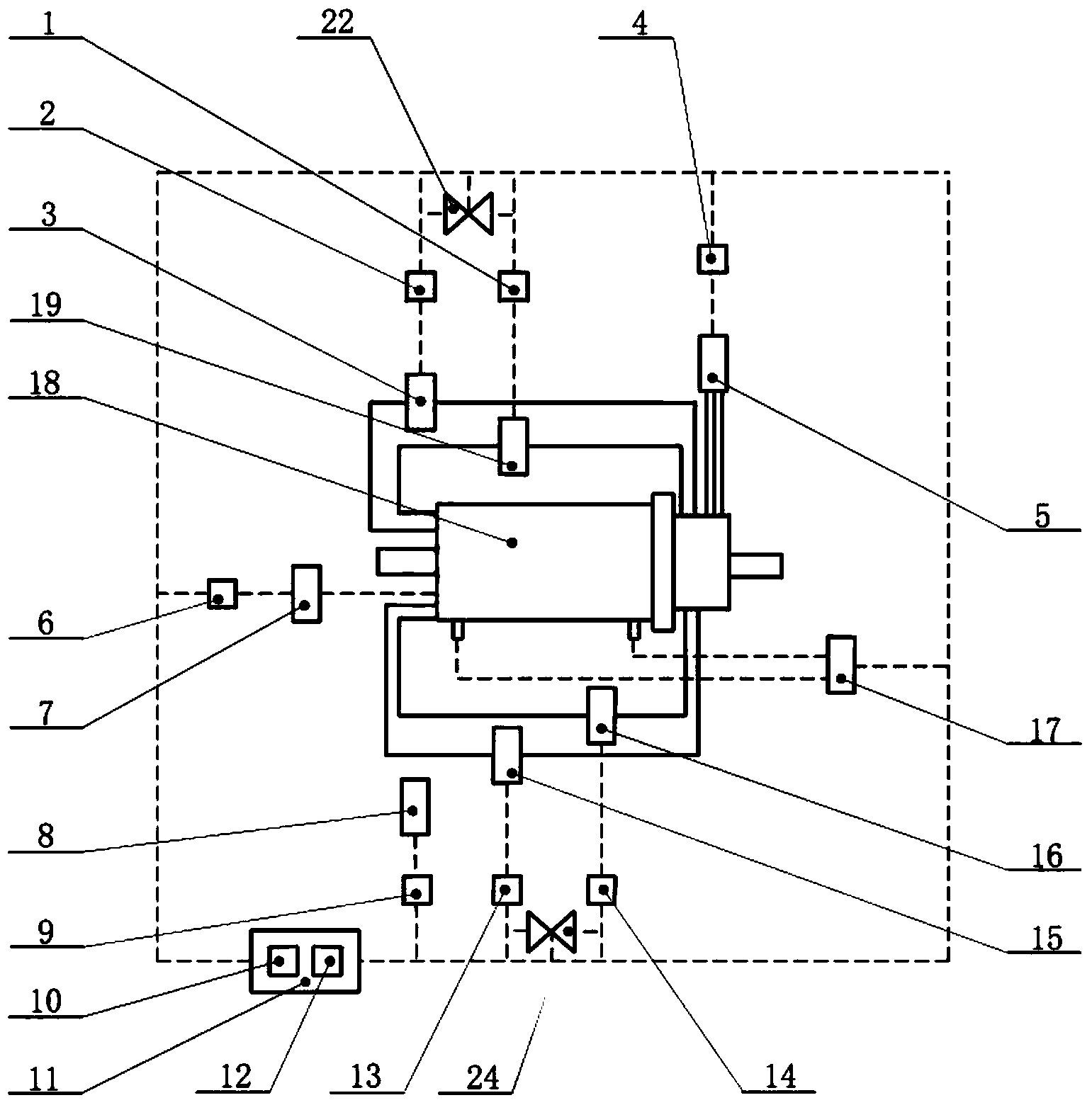

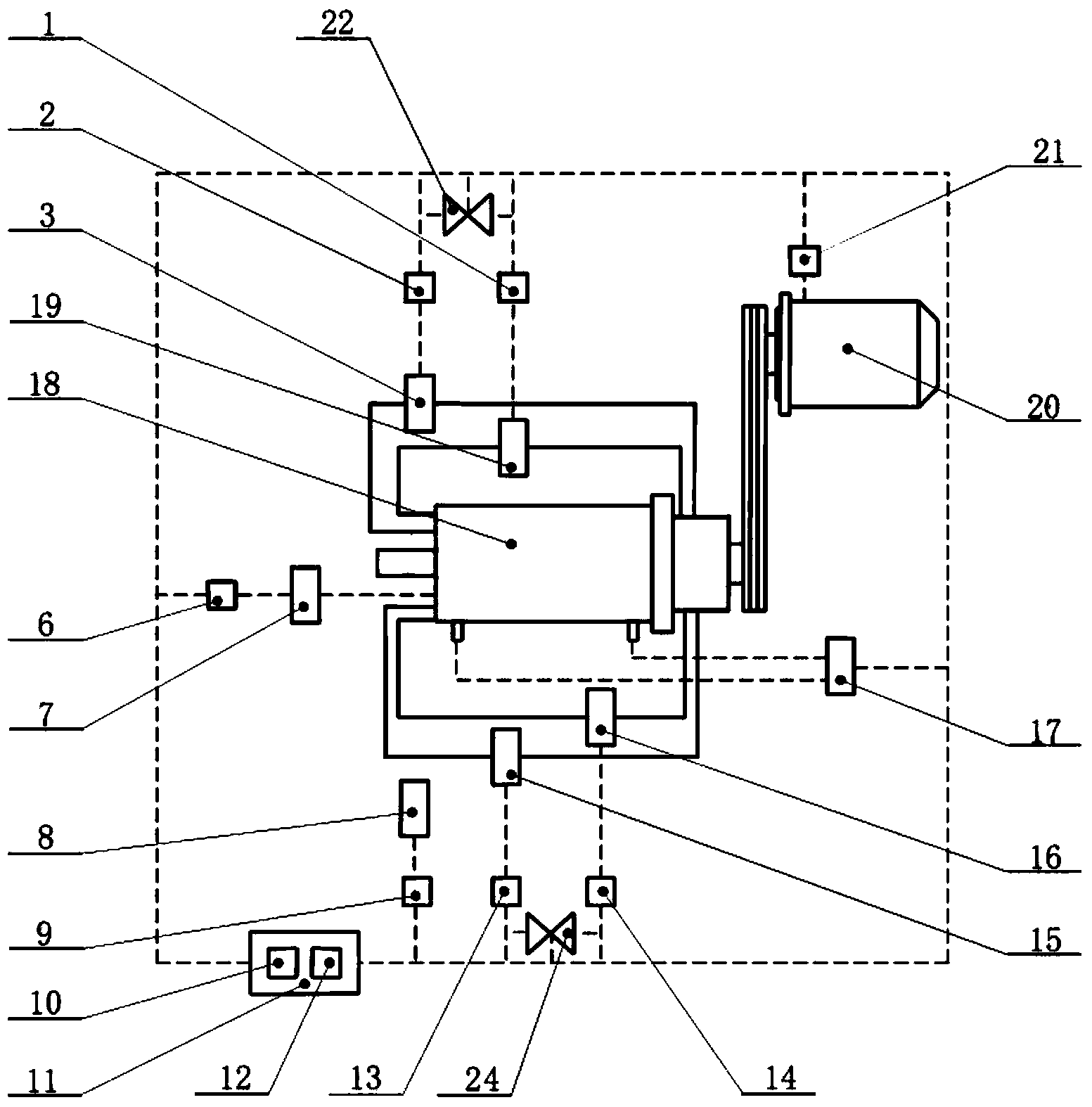

[0022] see Figures 1 to 3 , a precision spindle test device that can simulate working conditions, including two sets of lubricating circulation trunks, two sets of cooling circulation trunks, two sets of speed-torque drive devices, air sealing devices, constant temperature adjustment devices, temperature acquisition devices, Control system, the two sets of lubricating circulation trunks output different forms of lubricating fluid, each group of the lubricating circulation trunks includes a lubricating circulator and a sub-control unit for the lubricating circulator, and the lubricating circulator is provided with a lubricating fluid output A flow detection device and a mixing ratio detection device, the lubricating cycle machine sub-control unit is used ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap