Liquid sample drying device, dry sample test piece and preparation method thereof

A drying device and sample technology, applied in the field of dry sample test pieces, can solve problems such as the inability to use dry liquid samples, and achieve the effect of solving the aggregation phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

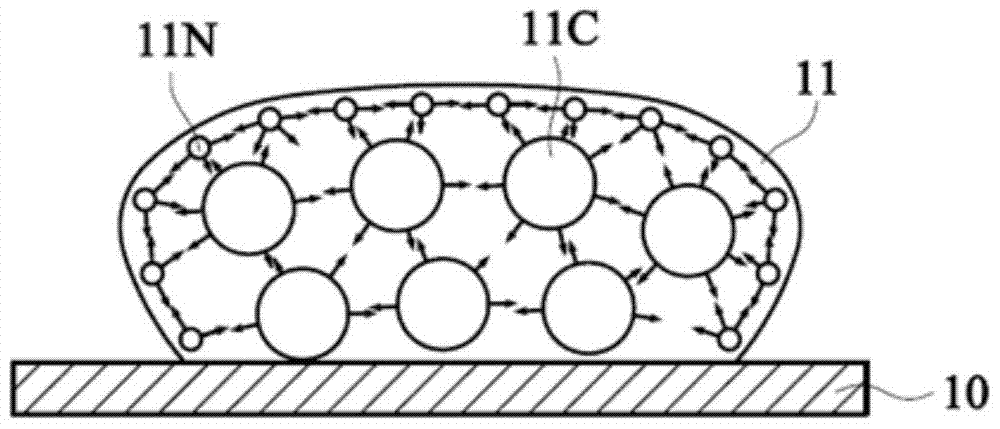

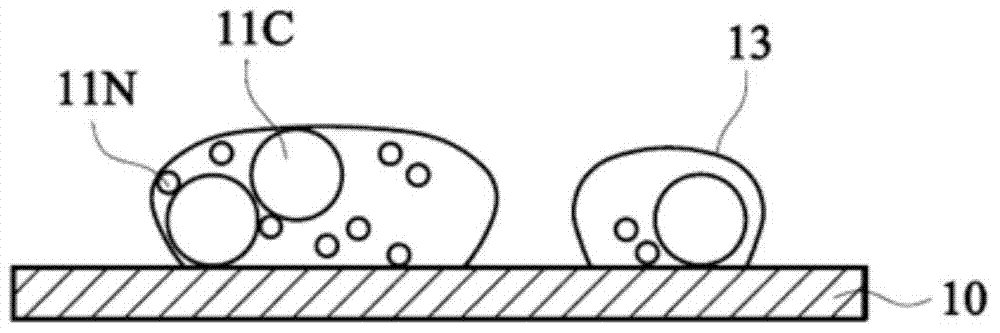

[0093] In order to better understand the concept of the present invention, multiple specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings. The same symbols represent members or devices having the same or similar functions. Wherein, the shapes, dimensions, proportions, etc. of the components shown in the drawings are only for illustration, and do not limit the implementation scope of the present invention. In addition, although any embodiment described in the following description discloses multiple technical features at the same time, it does not mean that all technical features in any one embodiment must be implemented at the same time. In addition, the manufacturing method of the liquid sample drying device of the present invention can be mass-produced through the existing semiconductor technology and / or MEMS technology. Wherein, the substrate is, for example, the first substrate 21 or the second su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com