Improved device for measuring air specific heat ratio through adopting vibration method

An improved technology of air specific heat capacity, which is applied in the field of measurement of physical constants, can solve problems affecting the accuracy of measurement, difficulty in realization, uncertainty, etc., and achieve the effects of reducing collision, reducing turbulence, and benefiting symmetry and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

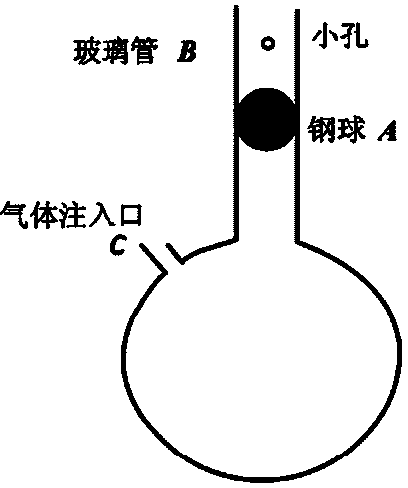

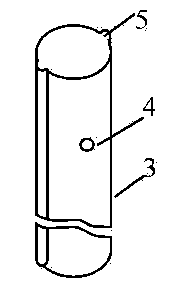

[0014] The same point as the prior art is that the parts of the device are the same, and all include a vibrating object and a glass tube 3, and a small hole 4 is arranged on the side of the glass tube 3.

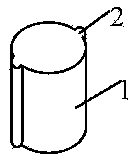

[0015] The steel ball in the prior art is replaced with a cylinder 1, and two or more ribs 2 are symmetrically distributed on the side of the cylinder 1, and the axes of all the ribs 2 are parallel to each other and the central axis of the cylinder 1, Preferably, 2-8 ribs 2 are blocked by the cylinder 1, and the distance between the cylinder 1 and the glass tube 3 is relatively small. Such a structure can effectively prevent the cylinder 1 from turning up and down.

[0016] Further, grooves 5 are set on the glass tube 3, and the number of grooves 5 corresponds to the number of ribs 2 on the side of the cylinder 1, that is, the number of grooves 5 is equal to the number of ribs 2 on the side of the cylinder 1. number, the rib 2 of the cylinder 1 slides up and down along the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com