Automatic autoclaved aerated concrete continuously matching system and control method thereof

A batching system, autoclaved gas filling technology, applied in the direction of electrical program control, program control, comprehensive factory control, etc., can solve the problems affecting production efficiency and cost, decentralized control of batching system, unable to monitor equipment, etc., to reduce hardware costs Expenditure, fully automatic control, high safety and reliability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with specific embodiments.

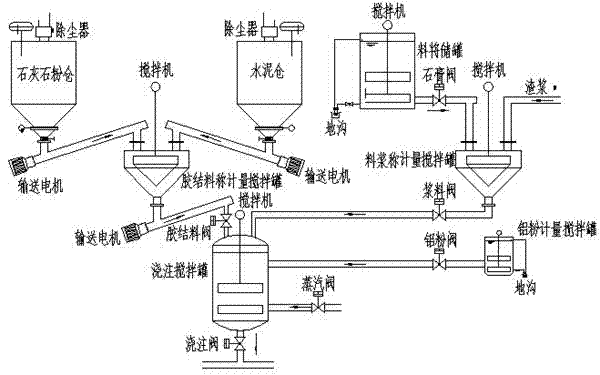

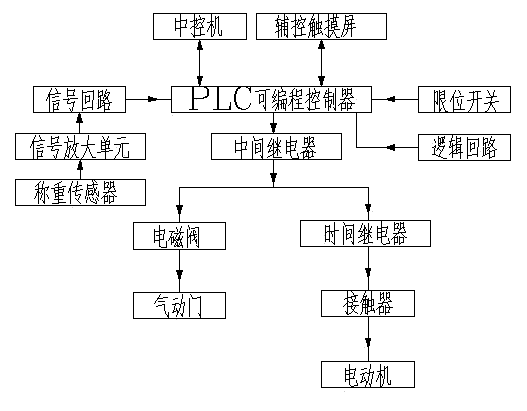

[0044] Such as figure 1 and figure 2 As shown, a control method for an autoclaved aerated concrete automatic continuous batching system includes the following steps:

[0045] Step 1. Set the formula data and production parameters required for ingredients through the upper computer, and issue production instructions. The upper computer

[0046] The machine is composed of a central control machine and an auxiliary control touch screen;

[0047] Step 2. Start the PLC programmable controller connected to the central control machine and the auxiliary control touch screen respectively by using the communication cable. The PLC programmable controller outputs and controls a plurality of intermediate relays to send control instructions to the execution components in the concrete mixing plant. Make each executive component act according to the production parameters set b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com