Wire winding device for rolling iron core transformer

A technology of winding device and transformer, applied in the direction of coil manufacturing, etc., can solve the problems of easy to produce core friction, easy softening of cardboard, long installation time, etc., to avoid damage to strength, fast assembly process, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further facilitate those of ordinary skill in the art to better understand the essence of the present invention, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

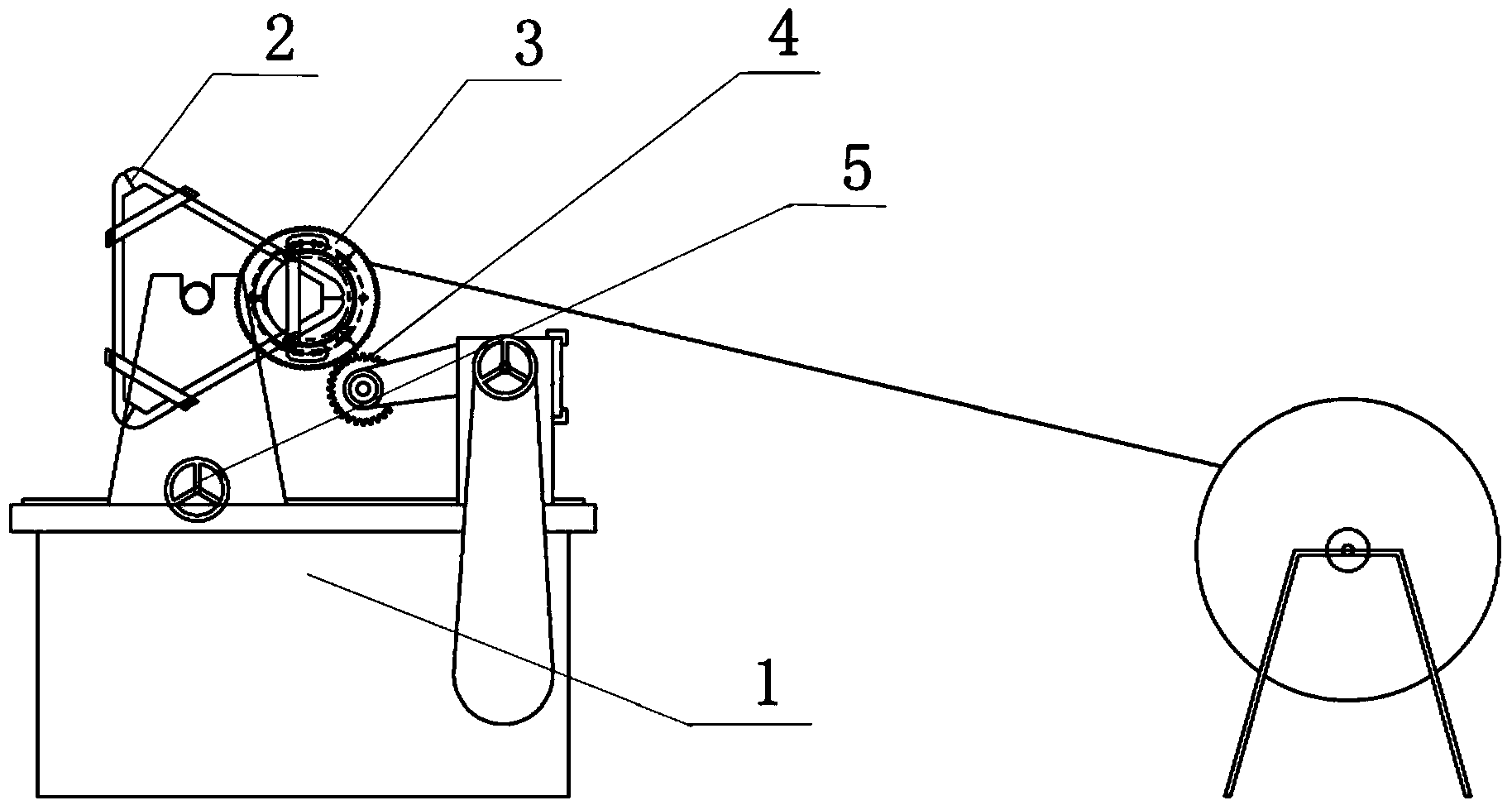

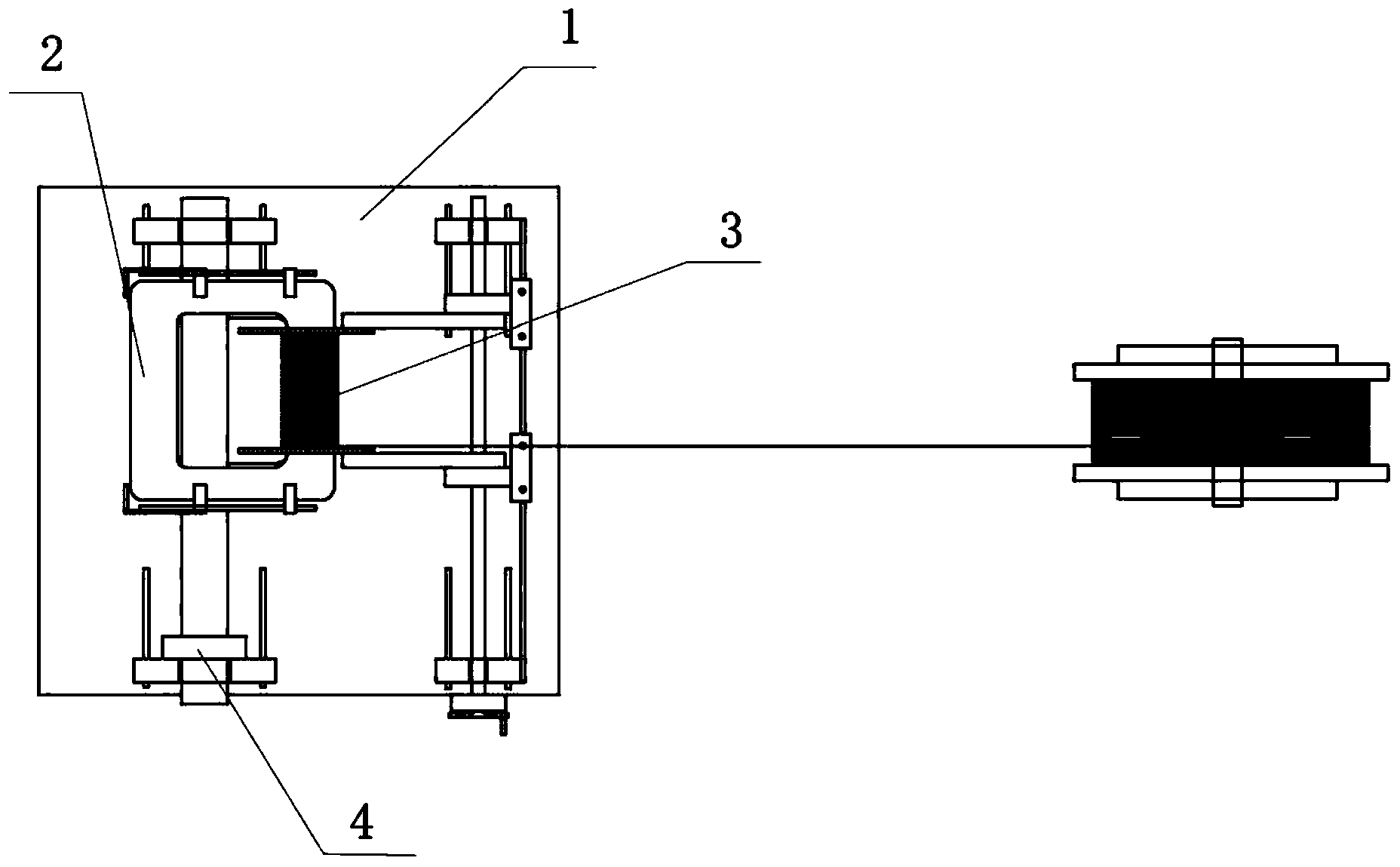

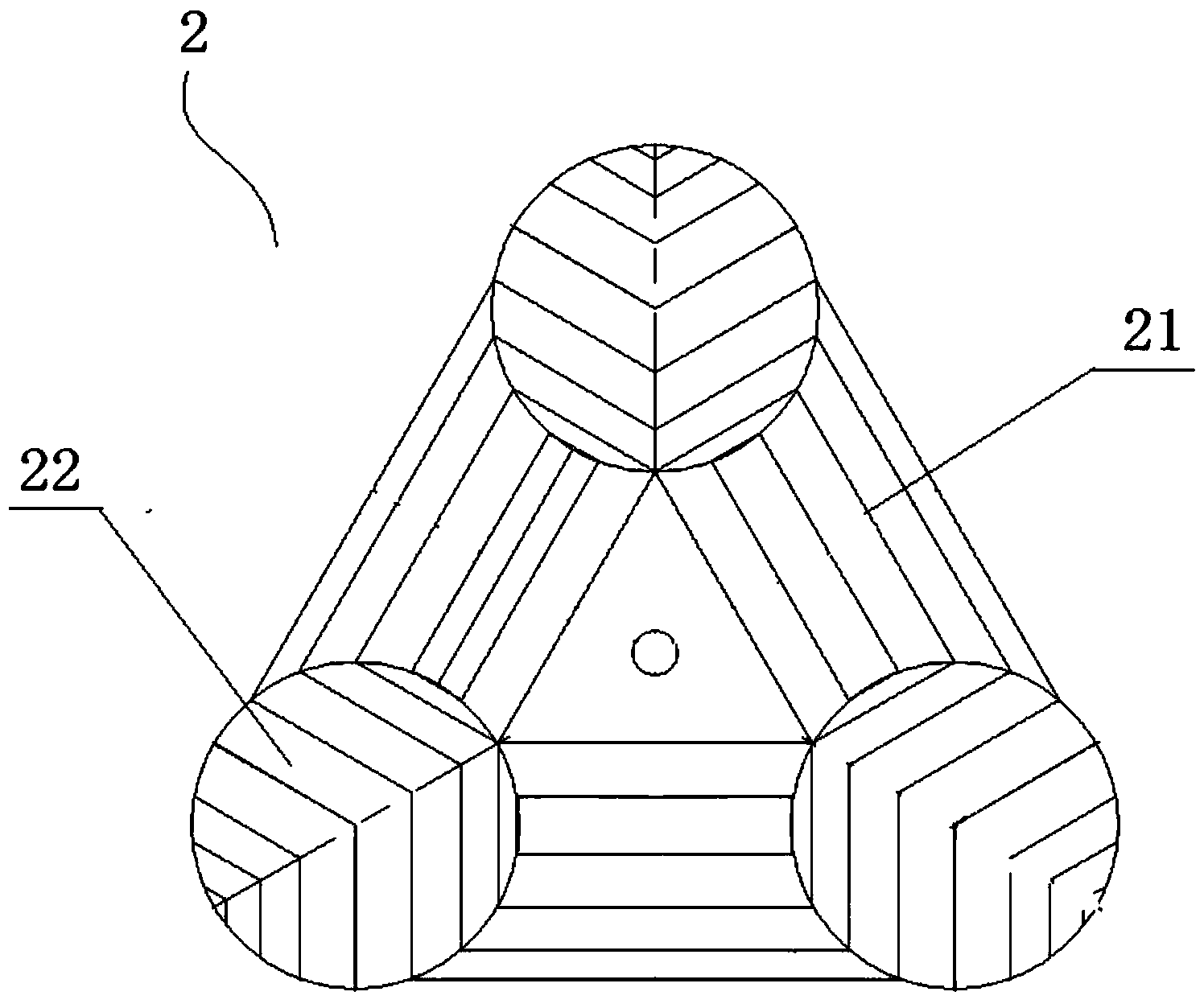

[0035] Such as Figure 1-Figure 2 As shown, a winding device for a wound core transformer includes: a frame 1 , an iron core 2 , a winding frame 3 , a driving gear 4 and a lifting device 5 .

[0036] The iron core 2 is installed on the machine base 1 through a lifting device 5 , and a winding frame 3 is movable outside the iron core 2 , and driving gears 4 are respectively arranged at both ends of the winding frame 3 . The iron core 2 is connected with the lifting device 5 through a turning gear, and a turning motor connected with the turning gear is provided on the machine base 1 .

[0037] During actual work, the driving gear drives the winding frame to rotate, thereby realizing winding. When the windi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com