Control processing method for extra-high voltage DC project operation in non-grounding-electrode mode

An ultra-high voltage DC, control processing technology, applied in the direction of DC network circuit devices, power transmission AC networks, electrical components, etc. The needs of engineering applications, the effect of reducing the current into the ground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

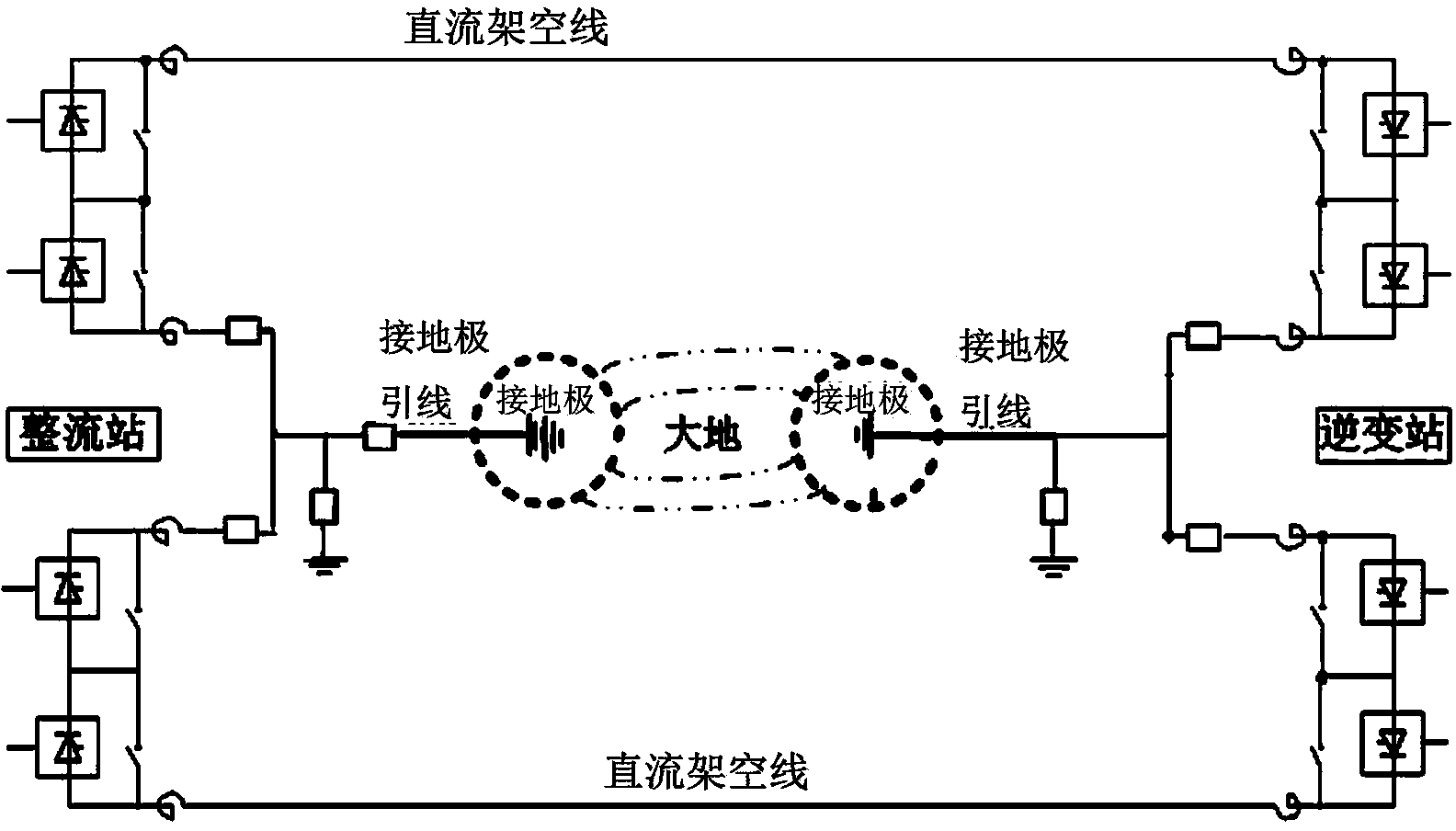

[0052] A control and processing method for UHV DC project without grounding electrode operation, which is aimed at such figure 2 The UHV DC project in the non-grounded mode is shown. compared to figure 1 , figure 2 The UHV DC system shown does not have the earth as the grounding electrode, but uses the grounding grid in the station as the grounding electrode. To operate effectively, it is necessary to maintain bipolar balance during operation.

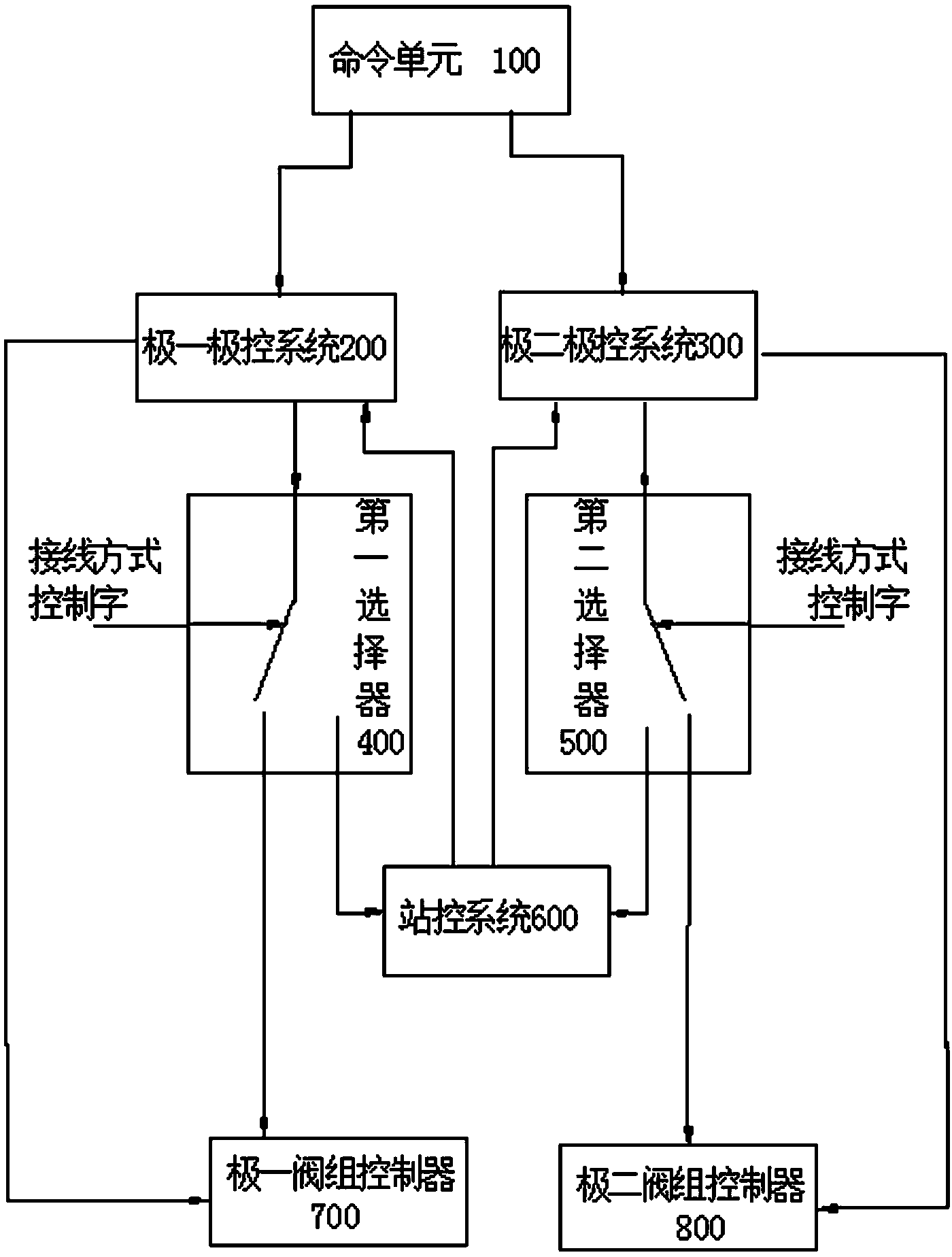

[0053] The invention is provided with a bipolar synchronous unlocking / blocking unit, a bipolar current following unit, a bipolar joint jump unit and an overload limiting unit. The bipolar synchronous unlocking / blocking unit performs bipolar synchronous unlocking / blocking processing, the bipolar current following unit performs bipolar current following processing, the bipolar joint jumping unit performs bipolar joint tripping processing, and the overload limiting unit performs limiting overload processing, The unlocking and emergen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com