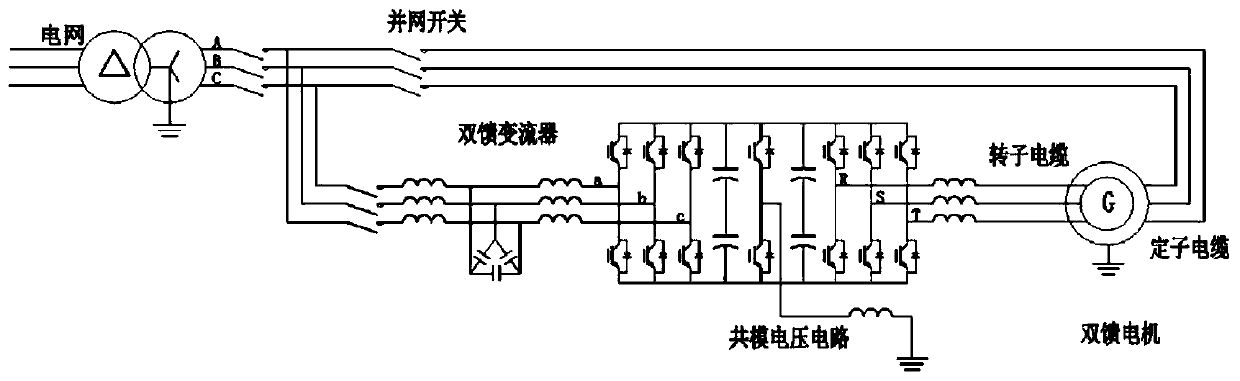

Common-mode voltage control method for doubly-fed motor converter system

A converter system, common mode voltage technology, applied in the generator control circuit, control system, control generator, etc., can solve the problems of rotor slip ring and rotor bearing failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

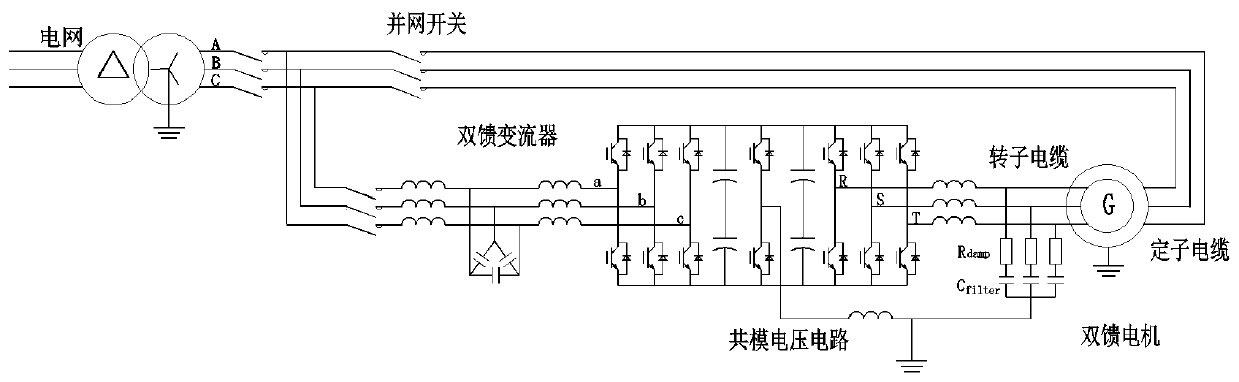

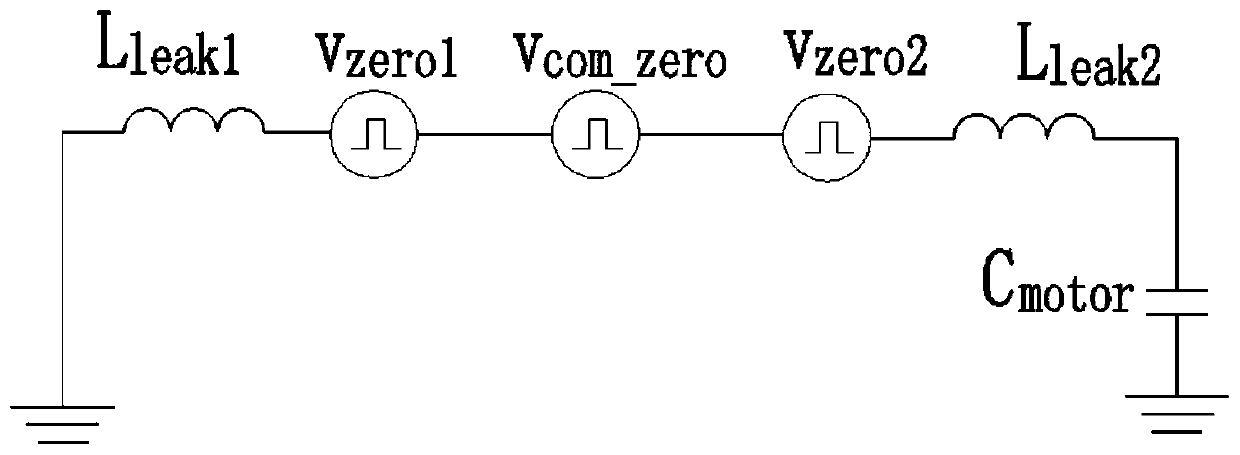

[0050] Such as Figure 1-4 As shown, 1. A doubly-fed generator converter common-mode voltage control method, a common-mode voltage generation circuit is added to the doubly-fed generator and converter circuit, the generation circuit adopts a bridge arm, connected to the DC On the bus; the control signal of the common-mode voltage injected into the bridge arm is the sum of the SPWM signals on the grid side divided by 3, and the sum of the SVPWM signals on the motor side divided by 3:

[0051]

[0052] That is: v com_zero2 (t)=v zero1 (t)+v zero2 (t),

[0053] Ideally: v zero1 (t)+v com_zero2 (t)+v zero2 (t) = 0;

[0054] Among them, the SPWM signal on the grid side is as follows: The SVPWM signal on the motor side is as follows:

[0055] The common-mode voltage injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com